6. USING THE OPERATION PANEL AND FRONT PANEL

RH-9800

19

6.

USING THE OPERATION PANEL AND FRONT PANEL

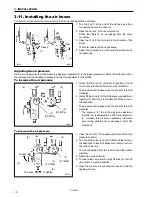

6-1. Panel button and switch names

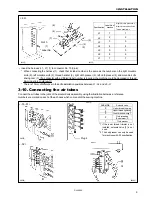

Operation panel part names

Front panel part name

POWER indicator

(A) SPEED indicator

1127Q

TROUBLE indicator

RESET button

Program number display window

CYCLE PROGRAM indicator

PROGRAM NUMBER button

AUTO mode Indicator

FEED mode indicator

MANUAL mode

indicator

PROGRAM mode indicator

MODE button

KNIFE button

AFTER indicator

OFF indicator

BEFORE indicator

(B) EYELET PATTERN indicator

(C) LENGTH indicator

(D) TACKING LENGTH indicator

(E) OFFSET indicator

(F) STITCH PITCH indicator

(M) SELECT button

(K) “Down” button

(I) KNIFE

POSITION indicator

(J) Front panel display

(L) “UP” button

(N) ENTER button

(H) CUTTING

SPACE

indicator

(G)No. OF

STITCHES

indicator

1126Q