9.

STANDARD ADJUSTMENTS

RH-9800

51

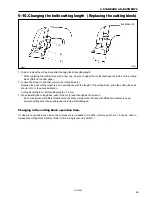

9-12. Replacing the knife

When replacing the knife with a new one, file the surface of the cutting block until smooth and until the knife does not

leave a mark on the cutting block.

Before replacing the knife, be sure to check that there is no gap between the knife (1) and the knife stopper (2).

1. Loosen the screw (3), and then remove the knife (1).

2. Insert the new knife (1) into the knife stopper (2), and then tighten it with the screw (3).

3. Adjusting the contact between the knife and cutting block. (Refer to the previous page.)

Note:

For L1 - L4 specifications, secure the knife stopper (2) in the position closest to you (the position indicated by the

dotted lines).

* When replacing the knife (1), make sure that the knife number matches the number for the eyelet shape.

Replace the knife and cutting block as a set.

If knives with different numbers are used on the same cutting block, accurate cutting will not be possible, and damage

to the knife may result.

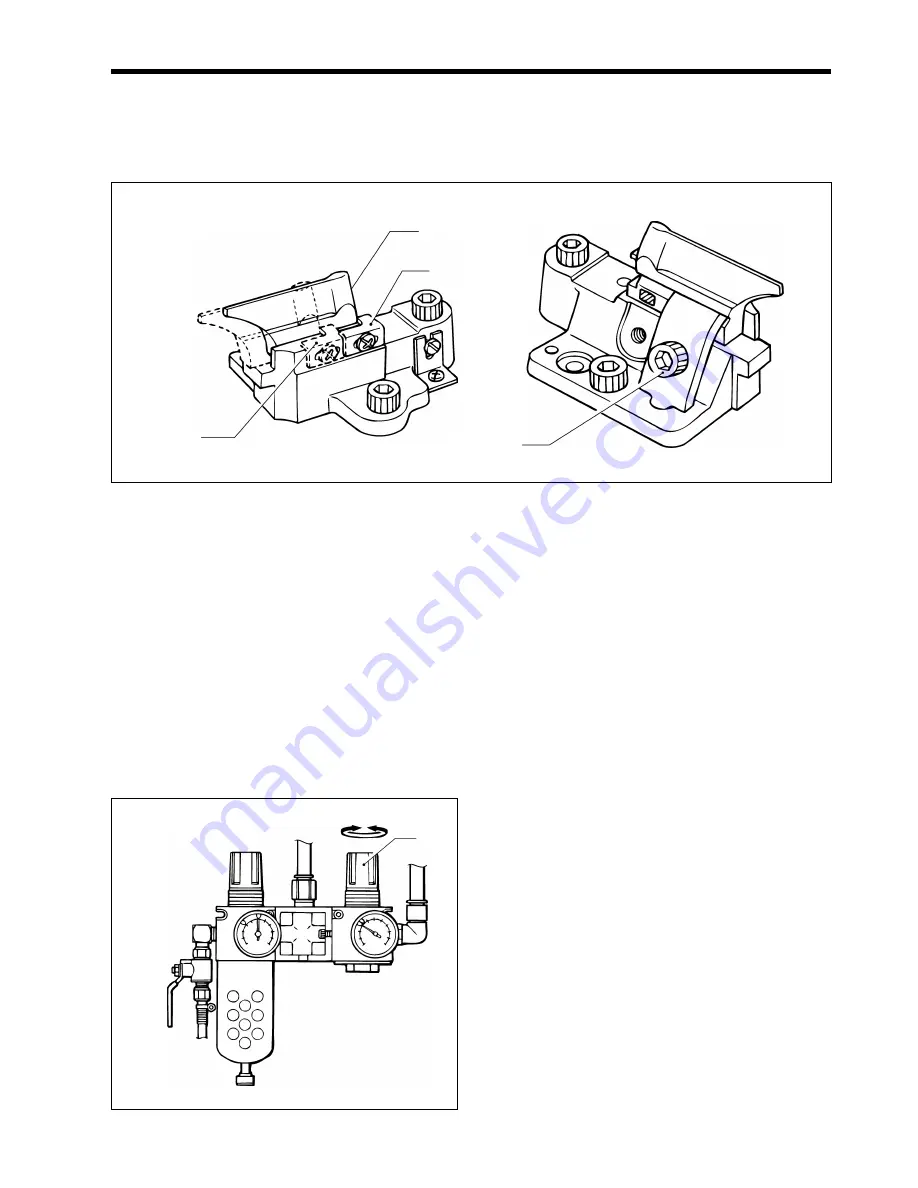

9-13. Adjusting the cutting pressure

Adjust the cutting pressure to the minimum pressure that still allows the material to be cut.

* If the knife cutting length is 20 mm, sufficient cutting performance can be obtained with an air pressure of 0.2 MPa.

To adjust the cutting pressure, adjust the air pressure of the knife pressure adjustment regulator (1) which is mounted

underneath the work table.

* If the cutting pressure is increased to more than is

necessary, it will cause the cutting block to become

worn or the knife to become damaged.

* If the material cannot be cut cleanly, do not increase

the cutting pressure over the maximum limit. Check

the contact between the knife and the cutting block,

while referring to "9-11. Adjusting the contact between

the knife and the cutting block".

(L 1 - L 4)

(1)

(2)

(3)

0973Q

0974Q

0975Q

(1)