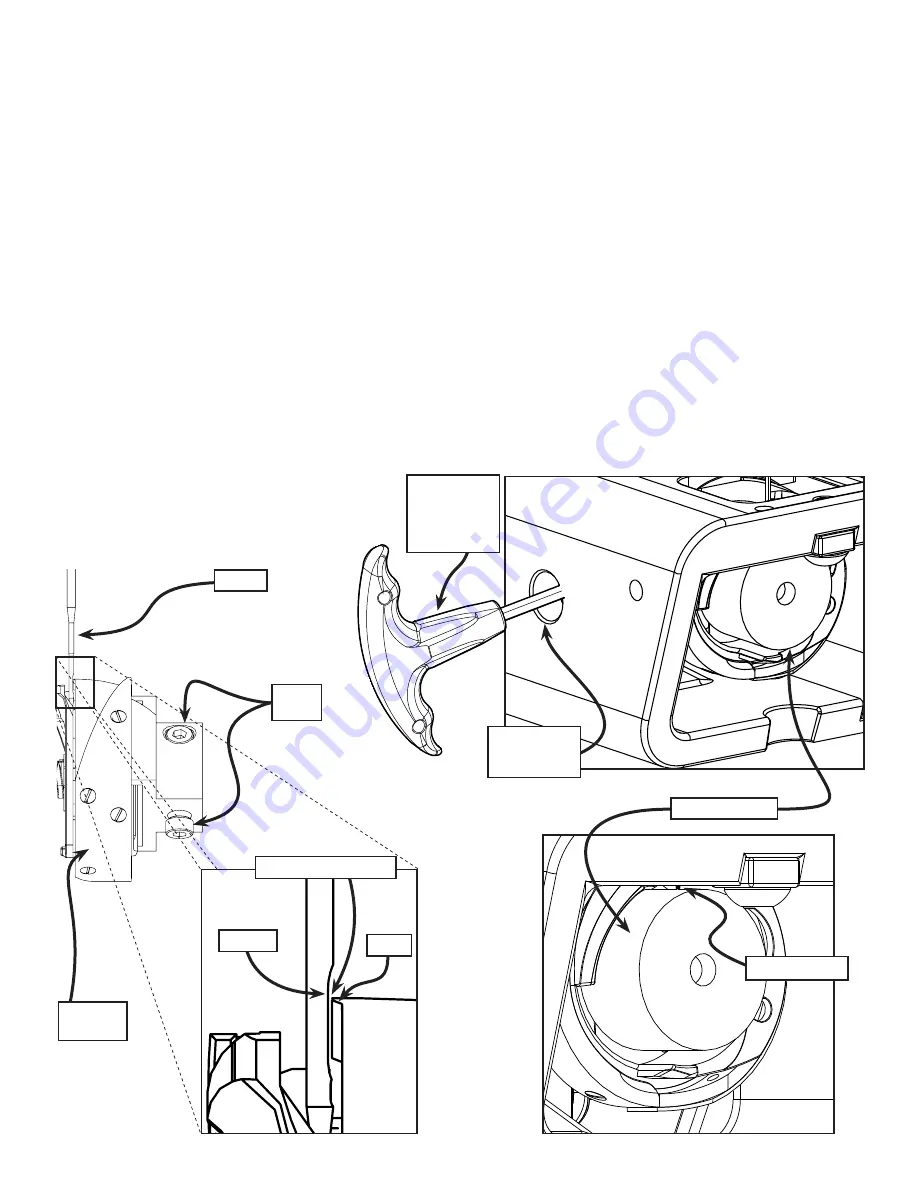

Timing The Machine

Parts Needed:

1. 2mm Allen Wrench

2. Timing Spacer

1.

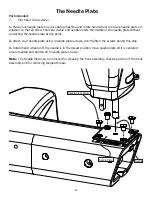

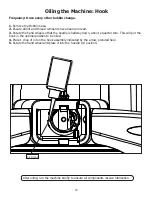

Loosen all three hook assembly set screws with a M2 allen wrench by inserting the wrench into

the machines timing hole when each set screw aligns with the hole.

2.

Rotate the handwheel clockwise from the front of the machine so needle is raising out of the hook

assembly.

3.

Bring the needle so it rests on the top of timing spacer, so the groove in the needle aligns in the

middle of the hook on the hook assembly. The needle should be as close as possible to the hook as-

sembly without touching, roughly between 0.02mm and 0.075mm.

4.

Tighten set screw, make sure needle doesn’t hit hook by watching to see if the needle bends

during rotation and there is no clicking noise. Rotate machine using the handwheel a full rotation to

ensure the needle doesn’t hit anywhere during rotation. If needle hits the hook assembly anywhere

during rotation adjust needle height up or down off center from hook in 0.25mm increments as ap

-

propriate to clear the collision.

5.

Tighten the two remaining set screws.

Note:

Only time the sewing machine if replacing hook assembly or machine comes out of timing.

Hook

Assembly

Needle

Set

Screws

Hook

Scarf

0.02-0.075mm Gap

Timing Hole

Cut Out

Timing Spacer

Tip Of Needle

2mm Allen

Wrench

26