Recommended Needle Style- 135x5, DPX5

(Equivalent Needle Styles-134, 135x7, 797, SY

1955)

Needle Size:

Thread Size and Type:

14/90

monofilament, 100 wt. silk, 60 wt.

polyester

16/100

monofilament, 60 wt., 50 wt. polyester or

cotton thread

18/110

40 wt. cotton and polyester, 30 wt.

cottons and polyester

20/125

any thread 30 wt. or heavier

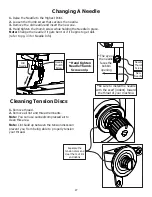

Needle Information

Change your needle:

• If you can hear your needle popping into your

fabric

• If your thread is breaking

• If you are getting skipped or uneven stitches

• If you are getting puckered or damaged

fabrics

• If there is a popping or clunking sound made

by the sewing machine, this may be a sign

that the needle is bent

• After 8 hours of use and at the beginning of

each project

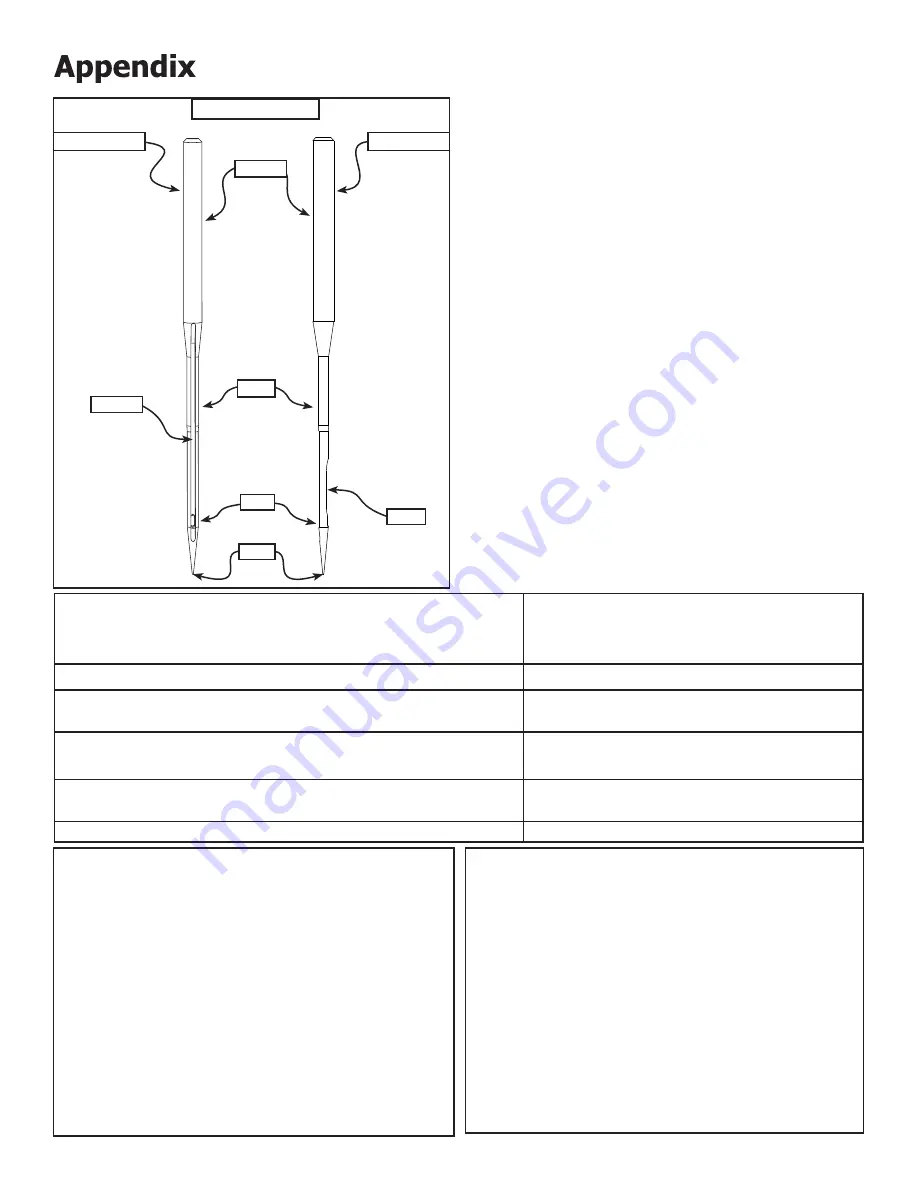

Shank -

The part of the needle that is held in the

needle bar

Shaft -

The long narrow part of the needle. The

diameter measurement is based on the shaft

Groove -

Allows the thread to pass through the

fabric more easily

Eye -

The hole near the tip of the needle for the

thread to pass through

Point -

The sharp end of the needle. There are

different types of points for different applications

It’s important that you change you needle when

the point dulls or you may damage your fabric

Scarf -

A cut away on the back of the needle

which allows the the hook on the bobbin

assembly to move past the needle and “hook” the

thread

Needle Diagram

Scarf

Eye

Point

Shaft

Shank

Front View

Side View

Groove

33

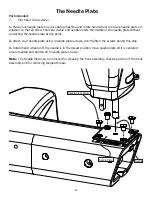

For the best results:

• Use the recommended needle style and make

sure it is properly positioned

• Change your needle after 8 hours of use and

at the beginning of each project

• Choose your needle size based on the weight

and type of the thread that you use

• Use a multidirectional needle