8 - 1 5

Confidential

8.5.5 Operational Check of LCD

(Function code 12)

n

Function

This function allows you to check whether the LCD on the control panel works normally.

n

Operating Procedure

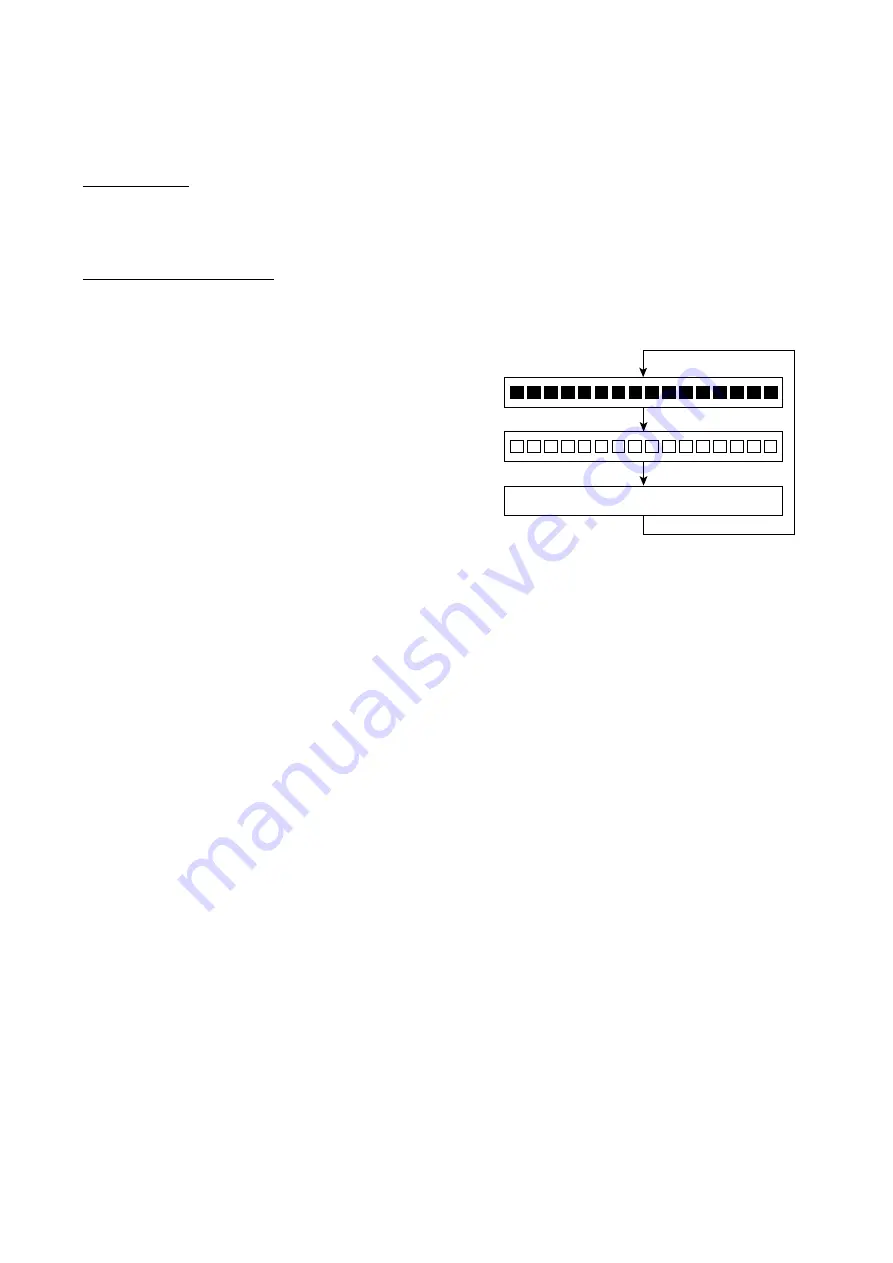

Checking the display state of the LCD:

(1) Press the

1

and

2

keys in this order in the initial

stage of the maintenance mode.

The LCD shows the screen given at right.

(2) Press the

Black

Start (Mono Start)

key.

Each time you press the

Black

Start (Mono

Start)

key, the LCD cycles through the

displays shown at right.

(3) Press the

Stop/Exit

key in any process of the above display cycle. The machine beeps for one

second and returns to the initial stage of the maintenance mode.

Black Start (Mono Start)

Black Start (Mono Start)

Black Start (Mono Start)

Summary of Contents for FAX 1840C

Page 1: ...Confidential FACSIMILE EQUIPMENT SERVICE MANUAL MODELS MFC3340CN 3240C FAX1940CN 1840C 1835C ...

Page 9: ...Confidential CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 18: ...Confidential CHAPTER 2 SPECIFICATIONS ...

Page 50: ...Confidential CHAPTER 3 THEORY OF OPERATION ...

Page 91: ...Confidential CHAPTER 4 TRANSFER OF DATA LEFT IN THE MACHINE TO BE SENT FOR REPAIR ...

Page 96: ...Confidential CHAPTER 5 DISASSEMBLY REASSEMBLY AND LUBRICATION ...

Page 167: ...5 69 Confidential Viewed from the left ...

Page 171: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...

Page 191: ...6 18 Confidential Vertical Alignment Check Patterns ...

Page 193: ...6 20 Confidential Margin Check Pattern ...

Page 202: ...Confidential CHAPTER 7 CLEANING ...

Page 205: ...Confidential CHAPTER 8 MAINTENANCE MODE ...

Page 216: ...8 9 Confidential Scanning Compensation Data List a b c d e f i ...

Page 236: ...8 29 Confidential 1st sheet 2nd sheet Vertical Alignment Check Patterns ...

Page 239: ...8 32 Confidential Margin Check Pattern ...

Page 249: ...Confidential CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING ...

Page 253: ...9 2 Confidential ...

Page 254: ...9 3 Confidential ...

Page 371: ...B Power Supply PCB U S A and Canadian models Confidential ...

Page 372: ...B Power Supply PCB European and Asian models Confidential ...

Page 401: ...Confidential February 05 SM FAX032 8XA901 5 Printed in Japan ...