GETTING READY

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

24

CAUTION

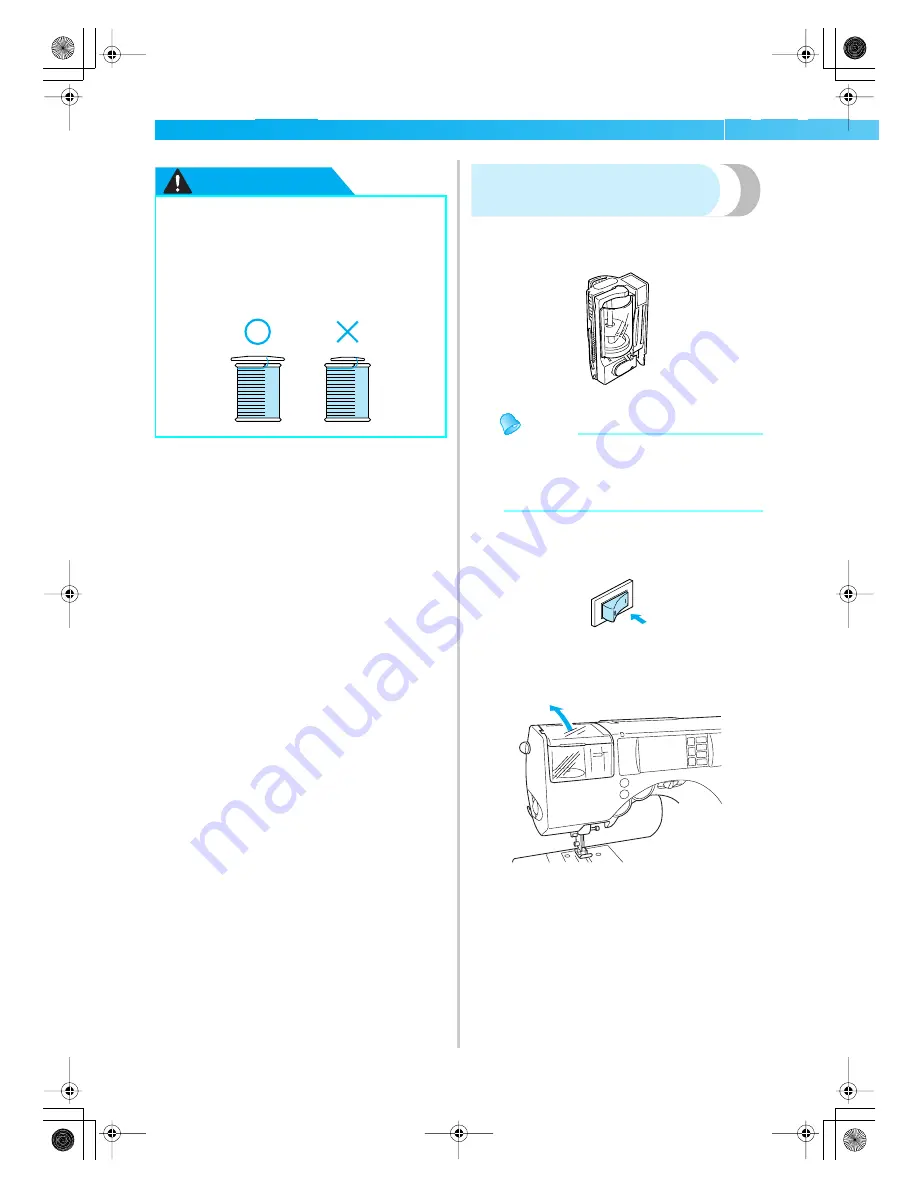

Loading the spool into the

thread cassette

Load the spool of thread into the thread cassette to

prepare the upper thread.

Memo

z

The order for threading the thread cassette is

indicated on the thread cassette. Also check

the markings on the thread cassette while

threading it.

a

Turn on the sewing machine.

b

Open the thread cassette compartment cover

at the top on the left side of the machine.

●

Two spool cap sizes are available,

allowing you to choose a spool cap that

best fits the size of spool being used. If

the spool cap is too small for the spool

being used, the thread may catch on the

slit in the spool or the needle may break.

SE-BrotherE_sgml.book Page 24 Monday, June 30, 2003 3:44 PM