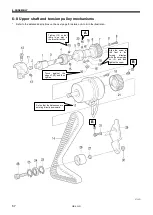

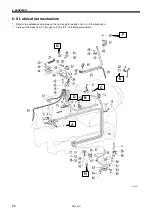

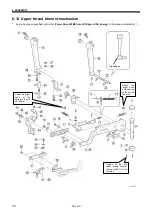

6. ASSEMBLY

HE-800B

73

G

1

)

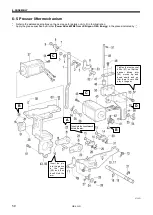

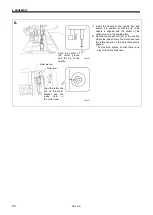

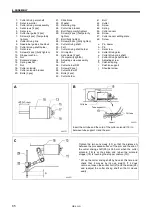

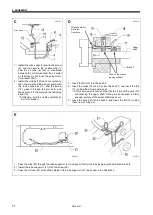

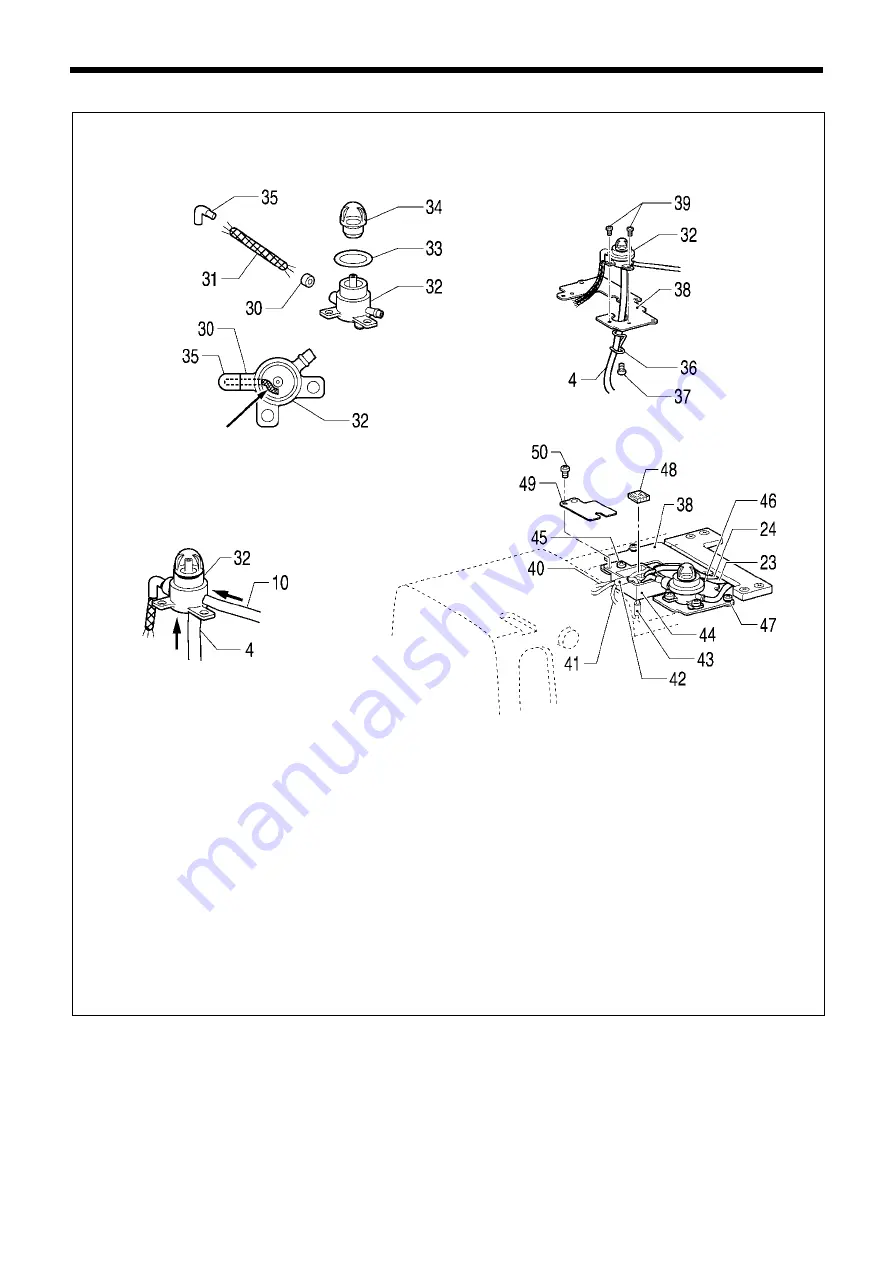

Pass the wick (31) through the collar (30), and then insert it into the oil terminal (32). Push the wick (31) firmly enough

into the groove as shown in the illustration.

2

)

Insert the packing (33) into the oil terminal (32), and then install the oil cap (34).

3

)

Pass the wick (31) through the oil pipe B (35), and then install it to the oil terminal (32).

4

)

Push the oil tube (10) that is connected between the oil terminal and the plunger pump into the oil terminal (32).

5

)

Push the oil tube (4) that is connected between the oil terminal and the oil outlet into the oil terminal (32).

6

)

Install the tube support (36) to the wick base support (38) with the screw (37).

7

)

Attach the oil tube (4) to the tube support (36), and then install the oil terminal (32) to the wick base support (38) with the

two screws (39).

8

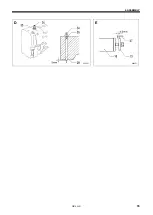

)

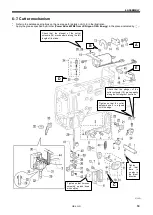

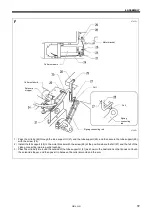

Pass the wick (40) of the needle bar bracket, the two wicks of the bush F, and the wick 41 coming from the thread

take-up support shaft through the oil tubes (42) and (43), and then install the wick base A (44) to the wick base support

(38) with the screw (45).

9

)

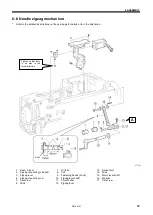

Install the oil tube (24) for lubricating the bush M and the zigzag lever shaft and the oil tube (23) for lubricating the

zigzag mechanism to the wick base support (38) with the fastening band (46).

10

)

Install the wick base support (38) with the two screws (47).

11

)

Insert the felt (48), and then install the cap (49) with the screw (50).

Push into the groove

0704D

0705D

0703D

0706D

Summary of Contents for HE-800B

Page 7: ...v HE 800B Oil tank accessory 4732M 4731M 4730M ...

Page 75: ...6 ASSEMBLY HE 800B 66 D E 0688D 0690D ...

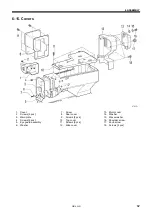

Page 126: ...9 ELECTRIC MECHANISM HE 800B 117 Power PCB Cutter PCB LCD panel PCB 0831D 0768D 0769D ...

Page 133: ...9 ELECTRIC MECHANISM HE 800B 124 0851D ...

Page 134: ...9 ELECTRIC MECHANISM HE 800B 125 0852D ...

Page 135: ...9 ELECTRIC MECHANISM HE 800B 126 0853D ...

Page 177: ...MEMO 168 HE 800B ...

Page 178: ...SERVICE MANUAL 2014 Brother Industries Ltd All Rights Reserved HE 800B I3061003D 2014 03 D 1 ...