78

APPENDIX

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

Troubleshooting

If the machine stops operating correctly, check the following possible problems before requesting service.

You can solve most problems by yourself. If you need additional help, the Brother Solutions Center offers

the latest FAQs and troubleshooting tips. Visit us at [http://solutions.brother.com].

If the problem persists, contact your dealer or the nearest authorized service center.

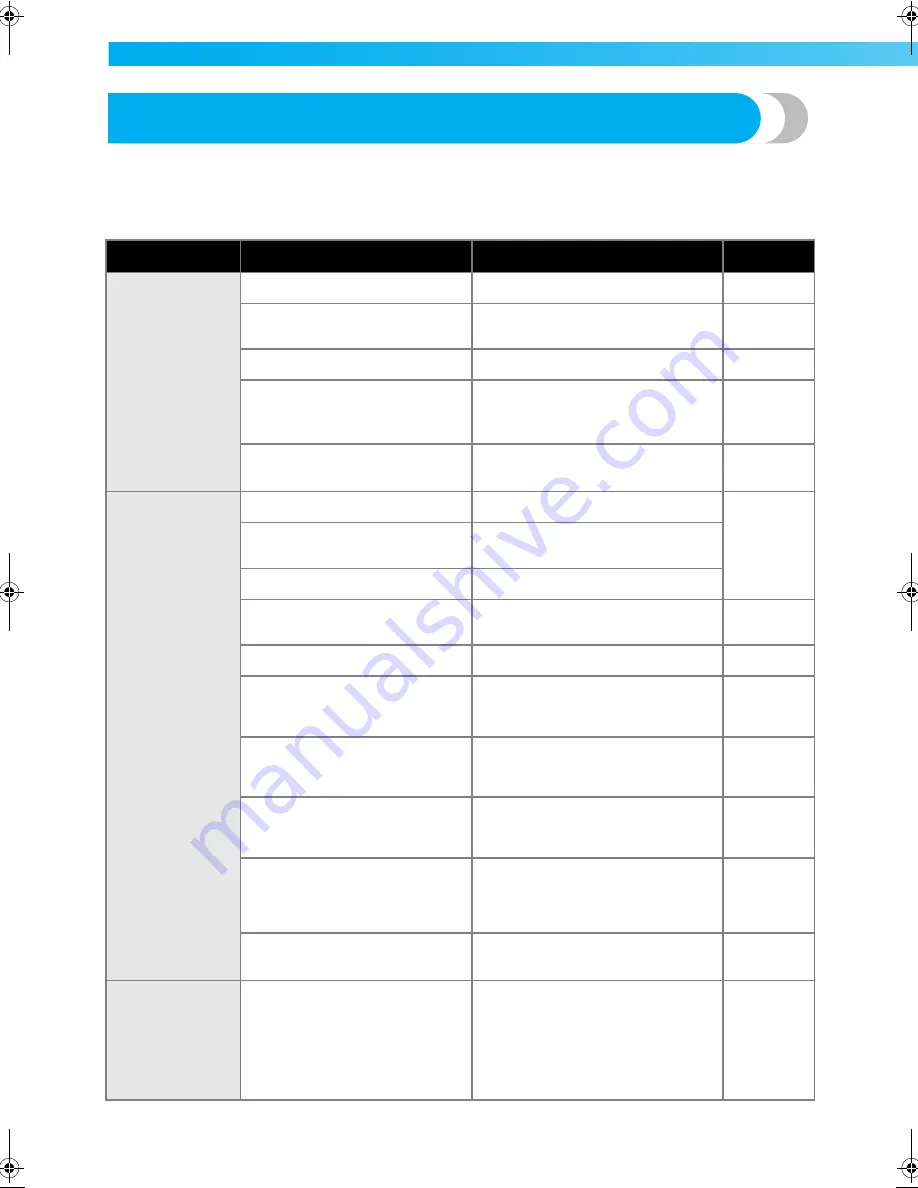

Symptom

Probable Cause

Remedy

Reference

The machine does

not operate.

The machine is not turned on.

Turn on the machine.

page 18

The start/stop button was not

pressed.

Press the start/stop button.

page 58

The presser foot lever is raised.

Lower the presser foot lever.

page 58

The bobbin winder shaft is on the

right side after winding the

bobbin.

Slide the bobbin winder shaft to the

left.

page 33

The embroidery unit is not

attached on the machine.

Attach the embroidery unit.

page 19

The needle breaks.

The needle is incorrectly installed. Correctly install the needle.

page 28

The needle clamp screw is loose.

Use the screwdriver to firmly tighten

the screw.

The needle is bent or blunt.

Replace the needle.

The upper thread tension is too

tight.

Loosen the upper thread tension.

page 63

The spool is incorrectly installed.

Correctly install the spool.

page 37

The area around the hole in the

needle plate is scratched, or has a

burr on it.

Replace the needle plate. Contact

your dealer or the nearest authorized

service center.

-

The area around the hole in the

embroidery foot is scratched, or

has a burr on it.

Replace the embroidery foot. Contact

your dealer or the nearest authorized

service center.

-

The bobbin case is scratched, or

has a burr on it.

Replace the bobbin case. Contact

your dealer or the nearest authorized

service center.

-

A bobbin designed specifically for

this machine is not used.

Incorrect bobbins will not work

properly. Only use a bobbin

designed specifically for this

machine.

page 29

The upper thread was not

threaded correctly.

Correct the upper threading.

page 38

The upper thread

breaks.

The upper thread was not

threaded correctly (for example,

the spool is not installed correctly,

the spool cap is too big for the

spool being used, or the thread

has come out of the needle bar

thread guide.)

Correct the upper threading.

Use the spool cap that best fits the

size of the spool being used.

page 37

appendix1 Page 78 Monday, August 18, 2008 8:08 PM

Summary of Contents for HE1

Page 2: ......

Page 16: ...14 ...

Page 91: ......

Page 92: ...English 885 V51 Printed in China XE5427 2013 ...