II - 13

1.5

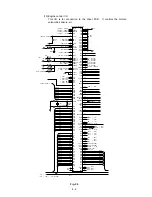

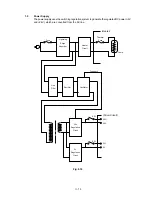

Power Supply

The power supply uses the switching regulation system to generate the regulated DC power (+5V

and +24V), which are converted from the AC line.

Heater

Circuit

Thermal

Fuse

Lightning

Surge

Absorber

Feedback

Line

Filter

Fuse

Rectifier

Oscillator

24V

Regulation

Circuit

5V

Regulation

Circuit

SW

SW

24VI

24V

5VI

5V

Lamp

(Heater)

(Driver Circuit)

Fig. 2.18