3-1

Confidential

CHAPTER 3 DISASSEMBLY AND

ASSEMBLY

1.

SAFETY PRECAUTIONS

To avoid creating secondary problems by mishandling, follow the warnings and precautions

below during maintenance work.

Note:

- Be careful not to lose screws, washers, or other parts removed.

- Be sure to apply grease to the gears and applicable positions specified in this chapter.

- When using soldering irons or other heat-generating tools, take care not to accidentally

damage parts such as wires, PCBs and covers.

- Static electricity charged in your body may damage electronic parts. When transporting

PCBs, be sure to wrap them in conductive sheets.

- When replacing the PCB and all the other related parts, put on a grounding wrist band and

perform the job on a static mat. Also take care not to touch the conductor sections on the flat

cables or on the wire harness.

- After disconnecting flat cables, check that each cable is not damaged at its end or

short-circuited.

- When connecting flat cables, do not insert them at an angle. After insertion, check that the

cables are not at an angle.

- When connecting or disconnecting harnesses, hold the connector body, not the cables.

If the connector is locked, release it first.

- After a repair, check not only the repaired portion but also handling of harnesses. Also check

that other related portions are functioning properly before operational checks.

- After an assembly, recommend the operation of “dielectric strength voltage check” and

“continuity check”.

- There must be no damage in the insulation sheet.

- After a repair, update the firmware to the latest version.

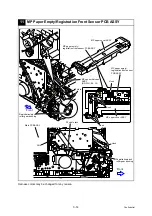

WARNING

Some parts inside the machine are extremely hot immediately after the machine is used.

When opening the front cover or back cover to access any parts inside the machine, never

touch the shaded parts shown in the following figures.