2-39

Confidential

4.

TROUBLESHOOTING

4.1 Error Cause and Remedy

■

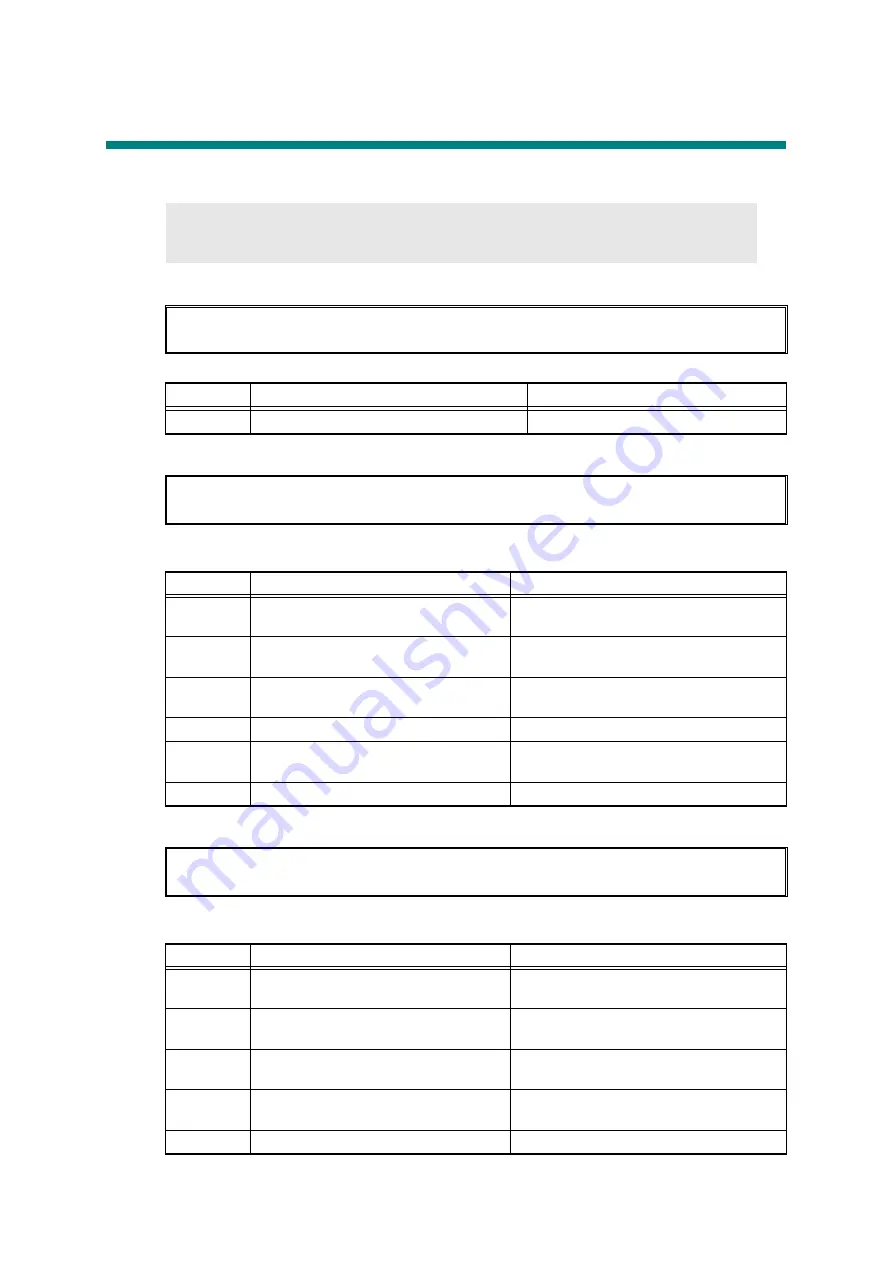

Error code 0100

ASIC error or motor driver error occurred.

■

Error code 0201

Synchronization signal from the main motor cannot be detected. Or the main motor speed is

unstable after a set period of time.

■

Error code 0202

Synchronization signal from the process motor cannot be detected. Or the process motor

speed is unstable after a set period of time.

Note:

This page shows LCD display for models without touch panel. It may differ from display

shown on models with touch panel.

Print Unable 01

Turn the power off and then back on again.

Step

Cause

Remedy

1

Main PCB failure

Replace the main PCB ASSY.

Print Unable 02

Turn the power off and then back on again.

Step

Cause

Remedy

1

Connection failure of the main motor

harness

Reconnect the main motor harness.

2

Connection failure of the low-voltage

power supply PCB harness

Reconnect the low-voltage power

supply PCB harness.

3

Part in the process drive unit

damaged

Replace the process drive unit.

4

Fuser unit damaged

Replace the fuser unit.

5

Low-voltage power supply PCB

failure

Replace the low-voltage power supply

PCB unit.

6

Main PCB failure

Replace the main PCB ASSY.

Print Unable 02

Turn the power off and then back on again.

Step

Cause

Remedy

1

Connection failure of the process

motor harness

Reconnect the process motor harness.

2

Connection failure of the low-voltage

power supply PCB harness

Reconnect the low-voltage power

supply PCB harness.

3

Part in the process drive unit

damaged

Replace the process drive unit.

4

Low-voltage power supply PCB

failure

Replace the low-voltage power supply

PCB unit.

5

Main PCB failure

Replace the main PCB ASSY.