4 - 11

Adjustment

Adjustment

Clearance between needle and rotary hook point

1. Attach the front cover assy..

2. Remove the presser foot, the needle plate B and the needle plate A, and then remove the inner rotary hook.

3. Remove the label.

4. Start the test mode.

5. Select the pattern number “02” (3-point needle drop mode).

6. Move the needle to the left with the

(Reverse stitch button), and then turn the power off.

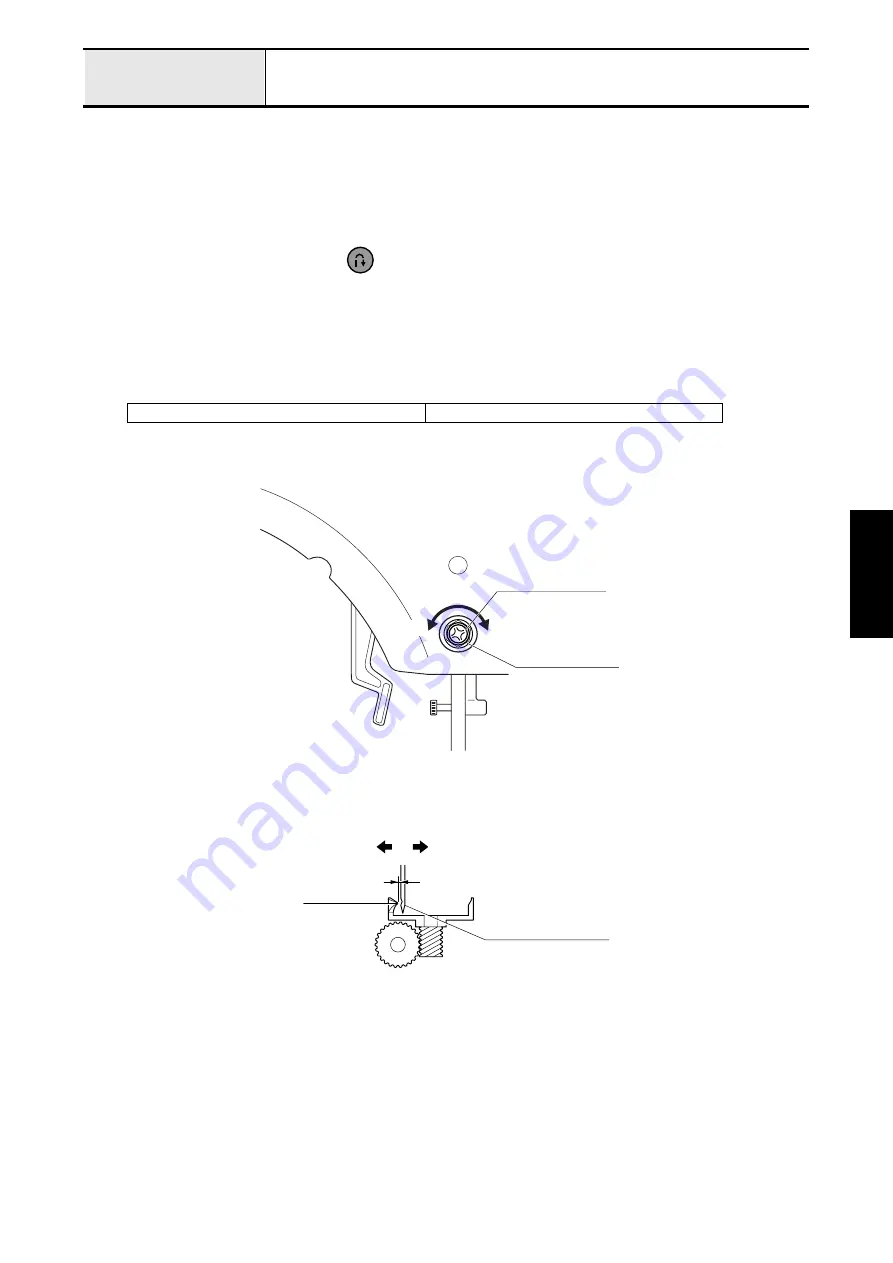

7. Loosen the screw (bind M3 x 25).

8. Turn the pulley by hand until the right edge of the needle aligns with the outer rotary hook point.

9. Turning the adjusting screw, adjust clearance between the needle and the outer rotary hook point (front and back)

to 0.1mm or less.

10. Tighten the screw (bind M3 x 25).

XE2396001

Box driver 7

Screw

(bind M3 x 25)

Adjusting screw

Rear cover

Hook point

0.1mm or less

Back

Front

Front

Size 75/11 needle

Back

Summary of Contents for HS-3000

Page 1: ......

Page 2: ......

Page 3: ......

Page 9: ...vi ...

Page 16: ...2 1 2 Disassembly Main parts 2 2 Feed unit 2 22 Needle presser unit 2 30 ...

Page 17: ...2 2 Main parts Main parts location diagram Main unit ...

Page 37: ...2 22 Feed unit location diagram Main unit ...

Page 45: ...2 30 Needle presser unit location diagram Main unit ...

Page 55: ...3 2 Main parts Main parts location diagram Main unit ...

Page 77: ...3 24 Main unit Main parts 36 Accessory table attachment 1 Attach the accessory table 1 1 ...

Page 78: ...3 25 Assembly Feed unit Feed unit location diagram Main unit ...

Page 90: ...3 37 Assembly Needle presser unit Needle presser unit location diagram Main unit ...

Page 163: ...7 12 ...

Page 164: ......