Troubleshooting

143

GETTING READ

Y

CONTENTS

SEWING BASICS

U

T

IL

IT

Y

S

T

ITCHES

APPENDIX

INDEX

Cancelling the operation

beep

When the sewing machine is purchased, it is set to

beep each time an operation panel key is pressed.

This setting can be changed so that the machine does

not beep.

1

Turn on the sewing machine.

X

The LCD comes on.

2

Press

(settings key) in the operation panel.

X

The settings screen appears.

3

Press , ,

and

(arrow

keys)

until

is selected.

4

Press

(OK

key).

X

The screen for changing the beep setting

appears.

5

Press

to

select .

To return to

, press

.

X

The machine is now set so that it will not

beep.

6

Press

(OK

key).

X

The initial stitch screen appears again.

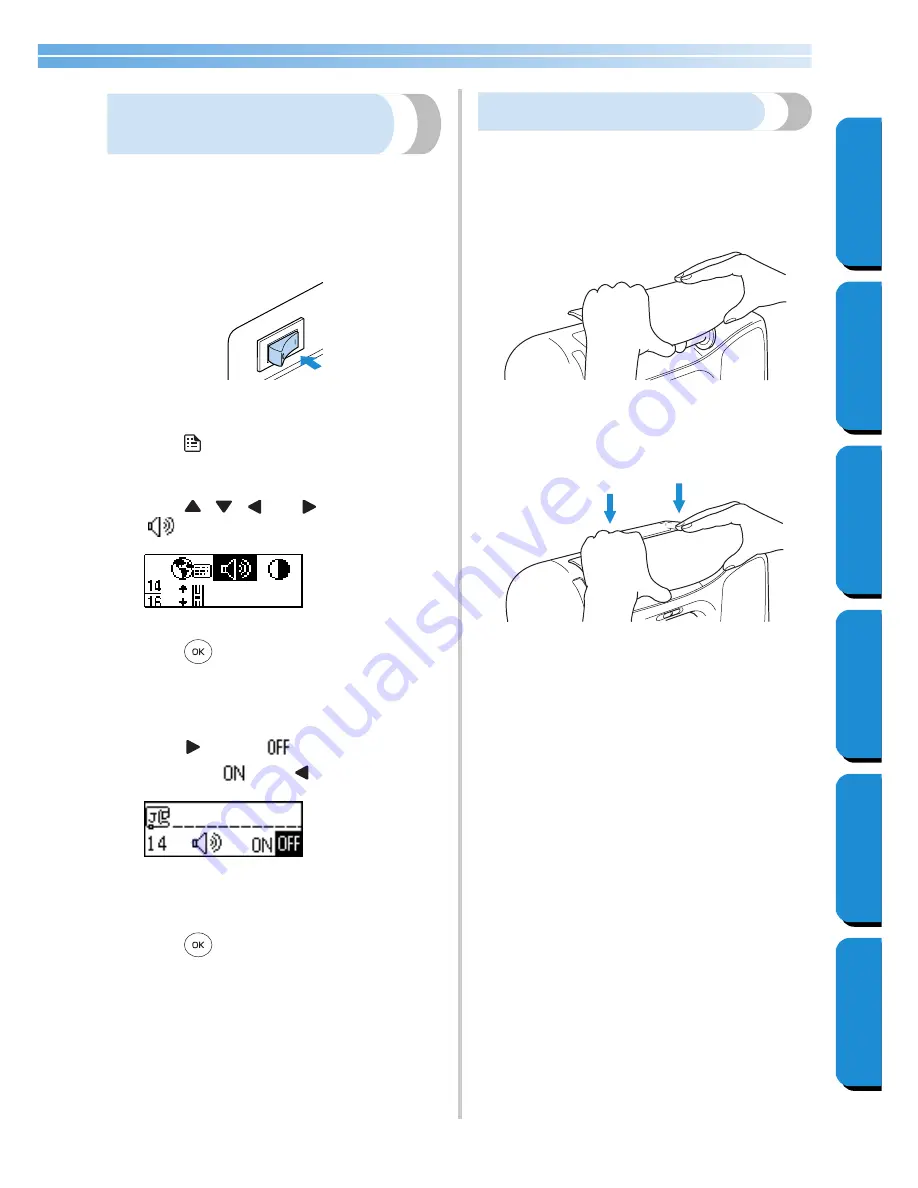

Removing the upper cover

If the upper cover of the sewing machine was

removed, re-attach it as described in the following

procedure.

1

Hold the upper cover level.

2

Push the upper cover down to re-attach it to

the machine.