KNOWING YOUR SEWING MACHINE

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

9

5

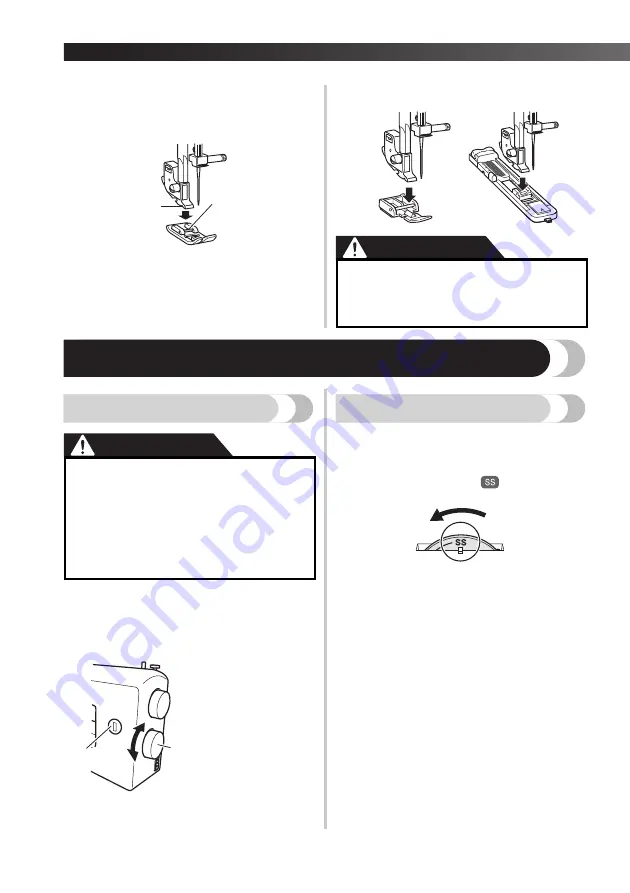

Lower the presser foot lever and fix the

presser foot onto the shank. If the presser

foot is in the correct place, the bar should

snap in.

1

Shank

2

Bar

■

Presser foot installation orientation

CAUTION

THE CONTROLS

Pattern selection dial

CAUTION

To select a stitch, simply turn the pattern selection dial,

located on the right side of the machine. The pattern

selection dial may be turned in either direction. The

next section shows recommended stitch lengths and

widths.

1

Pattern selection dial

2

Chosen pattern number

Stretch stitching

Raise the needle by turning the handwheel toward you

(counterclockwise) so that the mark on the wheel points

up.

Setting the stitch length dial to “

” changes the

selected pattern to a stretch stitch.

1

2

●

If the presser foot is not installed with

the correct orientation, the needle may

strike the presser foot, which may bend

or break the needle and cause injury.

●

When you use the pattern selection dial

to choose a pattern, raise the needle by

turning the handwheel toward you

(counterclockwise) so that the mark on

the wheel points up. If the needle is in

the down position when you turn the

pattern selection dial, the needle, presser

foot or fabric may be damaged.

• The pattern number

display does not rotate

endlessly. If you set

the pattern selection

dial to the highest or

lowest pattern and

continue to turn it in

the same direction, the

dial will spin freely but

the pattern will not

change.

1

2

Summary of Contents for JK2700NT

Page 50: ......

Page 51: ......

Page 52: ...English 885 X36 X38 888 X36 X38 Printed in Vietnam XF1764 1011 ...