3. INSTALLATION

11

KE-434C,435C

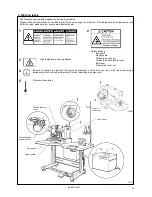

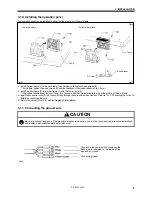

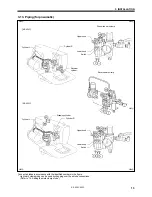

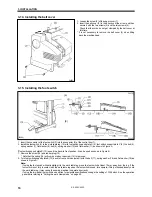

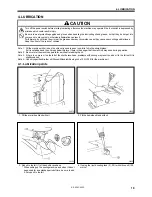

1. Gently tilt back the machine head.

Note:

After tilting back the machine head, do not push the face side or the pulley side from above.

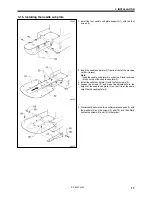

2. Pass the cord bundle (1) from the machine head through the hole (2) in the work table.

3. Gently return the machine head to its original position.

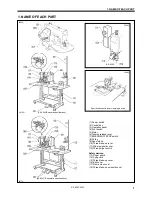

4. Remove the six screws (3), and then open the control box cover (main P.C. board mounting plate (4)).

Note:

When opening the cover, hold it securely so that it does not fall down.

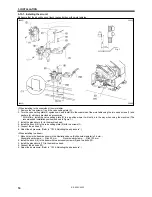

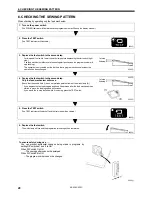

5. Loosen the two screws (5), and then open the cord presser plate (6) in the direction of the white arrow and pass the cord bundle

(1) through the opening.

6. Remove the screw (7), and then pass it through the terminal holes in the ground cord (8) from the machine head and the ground

cord (9) from the operation panel. Then re-tighten the screw (7) so that the ground cords (8) and (9) are secured as shown in the

illustration.

7. Remove the screw (10) , and then pass it through the terminal hole in the ground cord (11) from the upper shaft motor. Then re-

tighten the screw (10) so that the ground cord (11) is secured as shown in the illustration.

Note:

Make sure that the ground connections are secure in order to ensure safety.

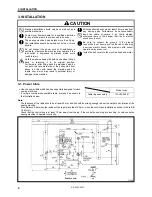

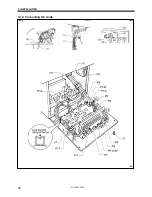

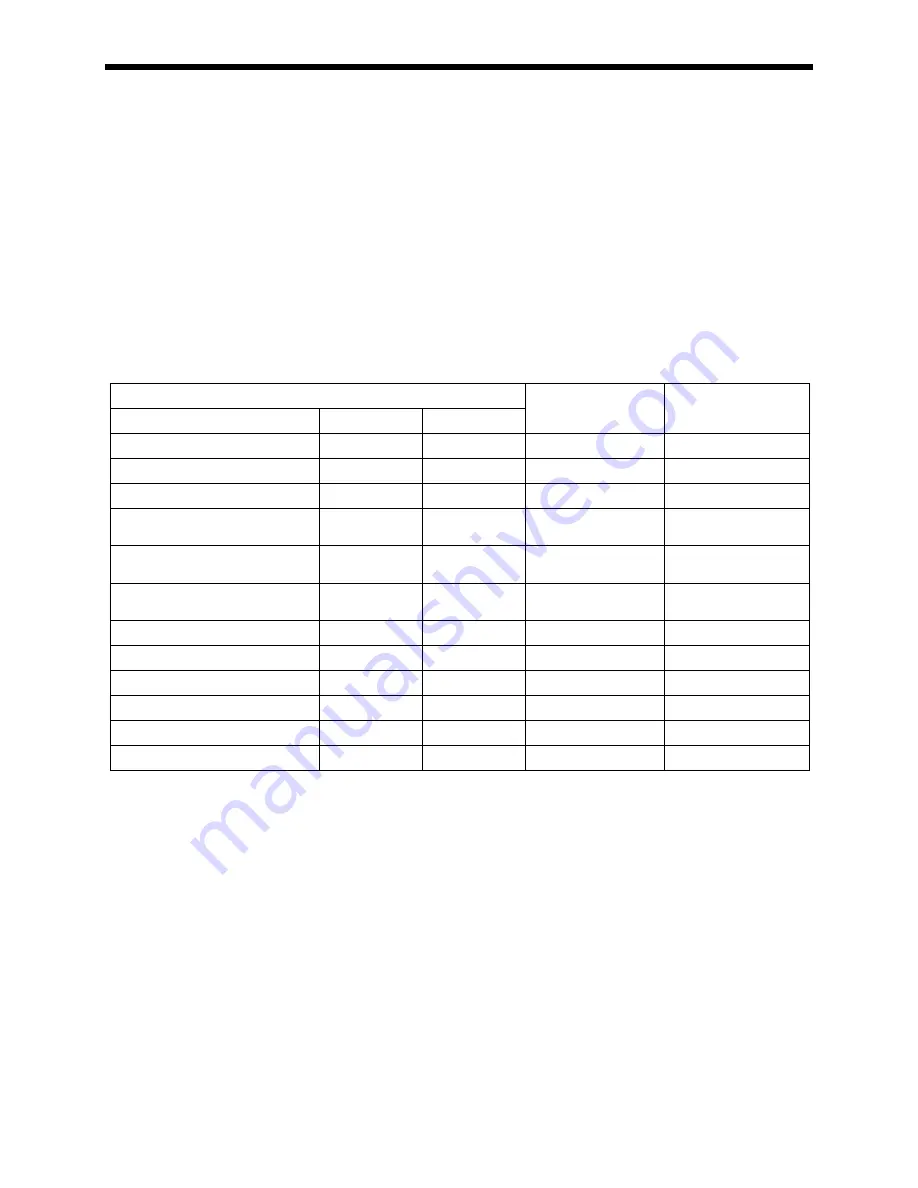

8. Securely connect connectors P1 to P8, P11, P14 (for pneumatic) and P18 as indicated in the table below.

Note:

Check that the connector is facing the correct way, and then insert it firmly until it locks into place.

Furthermore, lock the cord clamp at the top.

Machine head connectors

Connection location

No. of pins

Cord mark

Connection location

on circuit board

Cord clamps used

Head position switch

9-pin

[1A]

P1 - A (ORG1)

None

X, Y, Sewing sensor

12-pin

[1]

P1 - B (ORG2)

None

Synchronizer

5-pin

[2]

P2 (SYNCHRO)

(G)

Machine specification

select connector

8-pin

[3]

P3 (SELECT)

None

Thread wiper solenoid*

Thread take-up solenoid

5-pin

[4]

P4 (SOL2)

(G) (H)

Presser solenoid

Thread trimmer solenoid

4-pin

[5]

P5 (SOL)

(G) (H)

Pulse motor, Y

4-pin (blue)

[6]

P6 (YPM)

(G) (H)

Pulse motor, X

4-pin

[7]

P7 (XPM)

(G) (H)

Operation panel

26-pin

None

P8 (PANEL)

None

Upper shaft motor

3-pin

None

P11 (UVW)

(A)(B)(C)(D)(E)(F)

EMERGENCY STOP switch

6-pin

[18]

P18 (HEAD)

None

Solenoid valve (for pneumatic)

12-pin

None

P14 (AIR)

(A)(B)(C)(D)

* Provided as an option for solenoid specifications.

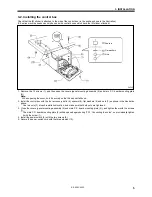

9. Secure the cord bundle (1) with the cord clamps (12) and (13).

10. Close the cord presser plate (6) in the direction of the black arrow, and secure it by tightening the screws (5).

Note:

Check that the cords do not get pulled when the machine head is tilted back gently.