Summary of Contents for MFC-5200C

Page 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC5200C MFC890 ...

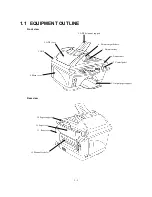

Page 7: ...CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 8: ...CHAPTER 1 PARTS NAMES FUNCTIONS CONTENTS 1 1 EQUIPMENT OUTLINE 1 1 1 2 CONTROL PANEL 1 3 ...

Page 13: ...CHAPTER 2 SPECIFICATIONS ...

Page 18: ...2 4 2 1 4 Environmental Condition ...

Page 23: ...CHAPTER 3 INSTALLATION ...

Page 26: ...3 2 3 2 UNPACKING THE MACHINE The equipment consists of the following major components ...

Page 34: ...CHAPTER 4 THEORY OF OPERATION ...

Page 54: ...CHAPTER 5 MAINTENANCE ...

Page 60: ...CHAPTER 6 DISASSEMBLY REASSEMBLY LUBRICATION AND ADJUSTMENT ...

Page 141: ...6 79 2 Separation roller and document feed roller 3 Document ejection roller ...

Page 146: ...6 84 11 Purge shaft EM4 Main chassis ...

Page 151: ...CHAPTER 7 MAINTENANCE MODE ...

Page 160: ...7 8 Scanning Compensation Data List ...

Page 174: ...7 22 Vertical Alignment Check Pattern ...

Page 183: ...CHAPTER 8 ERROR INDICATION AND TROUBLESHOOTING ...

Page 213: ...8 29 4 Close the manual feed cover ...

Page 214: ...MFC5200C MFC890 Appendix 1 Serial No Descriptions ...

Page 216: ... 2 PRINTER HEAD UNIT Location ...

Page 228: ...MFC5200C MFC890 Appendix 3 EEPROM Customizing Codes ...

Page 231: ...MFC5200C MFC890 Appendix 4 Firmware Switches WSW ...

Page 274: ...MFC5200C MFC890 Appendix 5 Re Packing Instructions ...

Page 276: ... 8 Place the machine in the original box with the original packaging material ...

Page 277: ...MFC5200C MFC890 Appendix 6 Wiring Diagram ...

Page 280: ...A Main PCB 1 4 MFC5200C ...

Page 281: ...A Main PCB 2 4 MFC5200C ...

Page 282: ...A Main PCB 3 4 MFC5200C ...

Page 283: ...A Main PCB 4 4 MFC5200C ...

Page 284: ...B Driver PCB 1 2 ...

Page 285: ...B Driver PCB 2 2 ...

Page 286: ...C NCU PCB MFC5200C ...

Page 287: ...D Control Panel PCB 1 2 MFC5200C ...

Page 288: ...D Control Panel PCB 1 2 MFC890 ...

Page 289: ...D Control Panel PCB 2 2 ...

Page 290: ...E Power Supply PCB MFC5200C ...

Page 291: ...F Carriage PCB ...

Page 292: ...G Media PCB 1 2 ...

Page 293: ...G Media PCB 2 2 ...