6-36

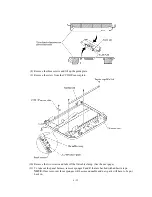

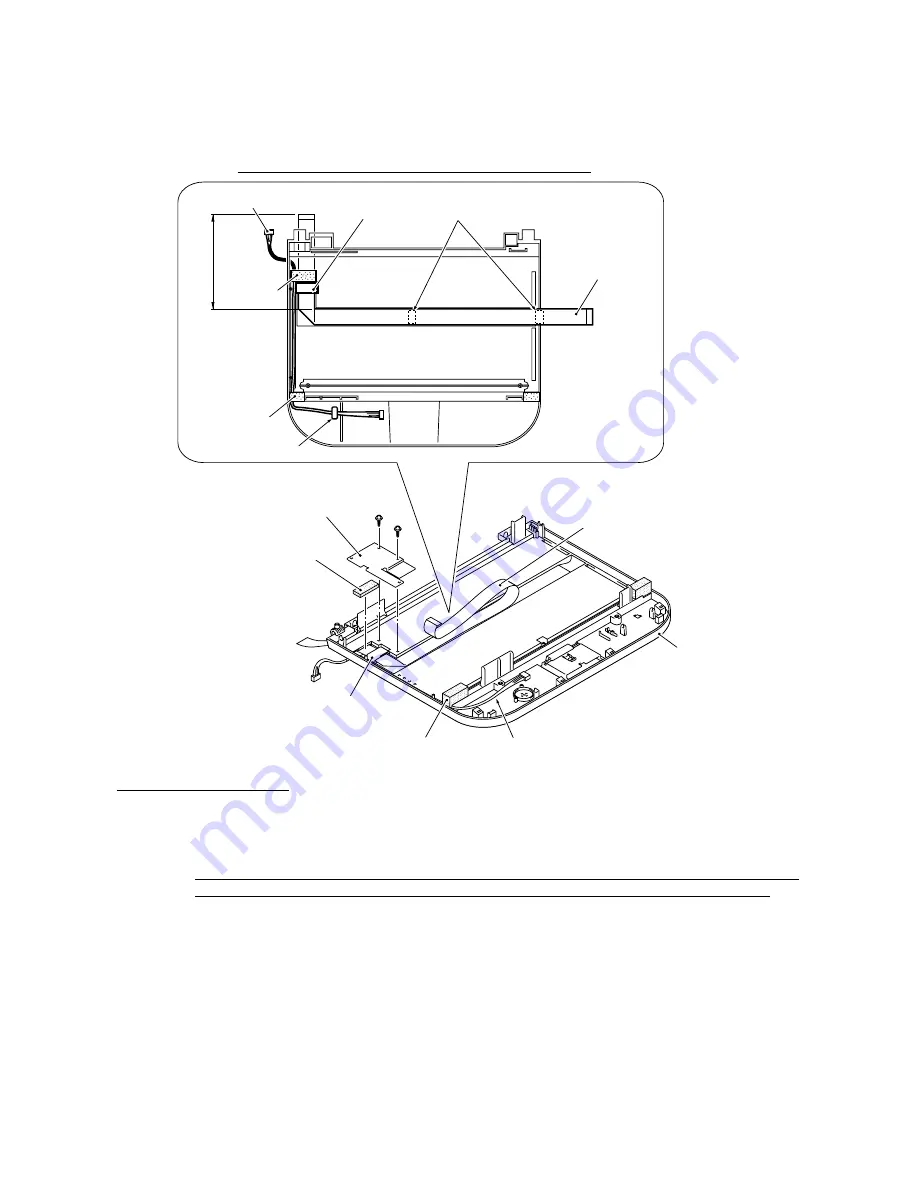

(12) To take out the CCD flat cable, remove sponge R.

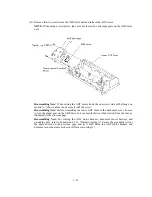

CCD flat cable and panel harness secured to the scanner base

Double-sided adhesive tape

CCD flat cable

Panel harness

Sponge F

Sponge R

210 mm

CCD flat cable

Flat cable clamp

Taptite,

cup B M3x8

Sponge R

(backed with adhesive tape)

Sponge F (backed with adhesive tape)

Panel harness

Scanner base

Ferrite core

Flat core

Flat core

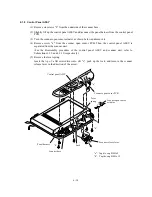

Reassembling Notes

• When using a new CCD flat cable, fold it and secure it to the scanner base with double-sided

adhesive tape and sponge R (backed with adhesive tape) as illustrated above.

Then attach it to the underside of the CCD unit with double-sided adhesive tape.

• When reassembling the components inside the scanner unit, use screws (Taptite, cup B M3x8).

Never use longer ones (e.g., M3x10). Using longer ones will bore a hole in the scanner base.

• When setting the CCD drive belt back to the scanner base, refer to page 6-33. Set the rear end of

the belt within the range specified on that page. At the left front end, hook the belt spring over

boss "b" and then check that the distance from the end of rib "c" to that of the looped belt is 23.3

to 25.3 mm. If the distance is out of the specification, remove the belt clip and adjust the belt

length. After that, set the belt spring holder.

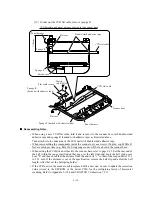

• If the CCD unit (or the scanner unit) is replaced with a new one, be sure to update the correction

value (stored in the EEPROM of the driver PCB) for the multiplying factor of horizontal

scanning. Refer to Appendix 2, A2.4 and CHAPTER 7, Subsection 7.5.11.

Summary of Contents for MFC-5200C

Page 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC5200C MFC890 ...

Page 7: ...CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 8: ...CHAPTER 1 PARTS NAMES FUNCTIONS CONTENTS 1 1 EQUIPMENT OUTLINE 1 1 1 2 CONTROL PANEL 1 3 ...

Page 13: ...CHAPTER 2 SPECIFICATIONS ...

Page 18: ...2 4 2 1 4 Environmental Condition ...

Page 23: ...CHAPTER 3 INSTALLATION ...

Page 26: ...3 2 3 2 UNPACKING THE MACHINE The equipment consists of the following major components ...

Page 34: ...CHAPTER 4 THEORY OF OPERATION ...

Page 54: ...CHAPTER 5 MAINTENANCE ...

Page 60: ...CHAPTER 6 DISASSEMBLY REASSEMBLY LUBRICATION AND ADJUSTMENT ...

Page 141: ...6 79 2 Separation roller and document feed roller 3 Document ejection roller ...

Page 146: ...6 84 11 Purge shaft EM4 Main chassis ...

Page 151: ...CHAPTER 7 MAINTENANCE MODE ...

Page 160: ...7 8 Scanning Compensation Data List ...

Page 174: ...7 22 Vertical Alignment Check Pattern ...

Page 183: ...CHAPTER 8 ERROR INDICATION AND TROUBLESHOOTING ...

Page 213: ...8 29 4 Close the manual feed cover ...

Page 214: ...MFC5200C MFC890 Appendix 1 Serial No Descriptions ...

Page 216: ... 2 PRINTER HEAD UNIT Location ...

Page 228: ...MFC5200C MFC890 Appendix 3 EEPROM Customizing Codes ...

Page 231: ...MFC5200C MFC890 Appendix 4 Firmware Switches WSW ...

Page 274: ...MFC5200C MFC890 Appendix 5 Re Packing Instructions ...

Page 276: ... 8 Place the machine in the original box with the original packaging material ...

Page 277: ...MFC5200C MFC890 Appendix 6 Wiring Diagram ...

Page 280: ...A Main PCB 1 4 MFC5200C ...

Page 281: ...A Main PCB 2 4 MFC5200C ...

Page 282: ...A Main PCB 3 4 MFC5200C ...

Page 283: ...A Main PCB 4 4 MFC5200C ...

Page 284: ...B Driver PCB 1 2 ...

Page 285: ...B Driver PCB 2 2 ...

Page 286: ...C NCU PCB MFC5200C ...

Page 287: ...D Control Panel PCB 1 2 MFC5200C ...

Page 288: ...D Control Panel PCB 1 2 MFC890 ...

Page 289: ...D Control Panel PCB 2 2 ...

Page 290: ...E Power Supply PCB MFC5200C ...

Page 291: ...F Carriage PCB ...

Page 292: ...G Media PCB 1 2 ...

Page 293: ...G Media PCB 2 2 ...