V

- 15

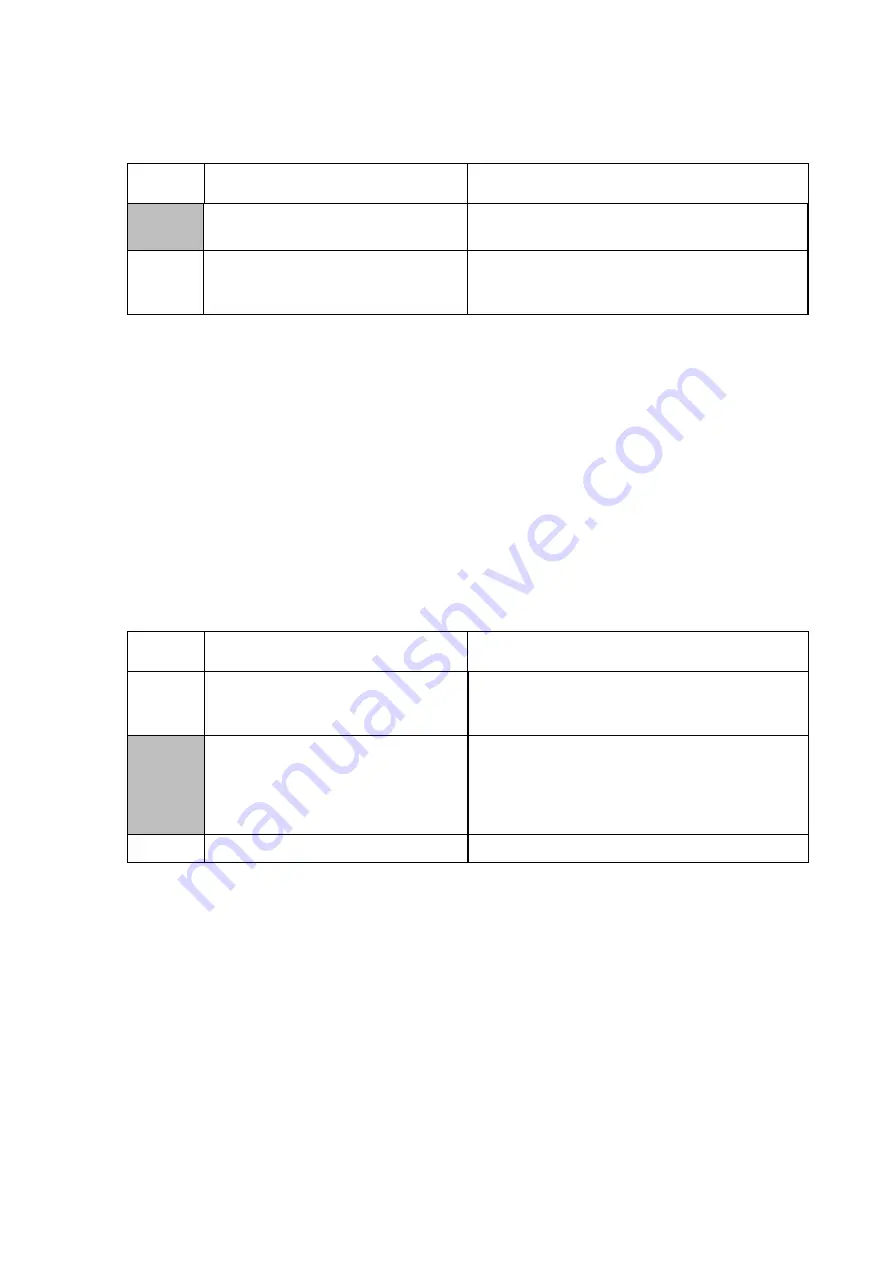

WSW23

(Communications setting)

Selector

No.

Function

Setting and Specifications

1

Starting point of training check

(TCF)

0: From the head of a series of zeros

1: From any arbitrary point

2

|

8

Not used.

l

Selector 1:

Starting point of training check (TCF)

At the training phase of receiving operation, the called station detects for 1.0 second a training check

(TCF) command, a series of zeros which is sent from the calling station for 1.5 seconds to verify

training and give the first indication of the acceptability of the line.

This selector sets the starting point from which the called station should start counting those zeros. If

this selector is set to "0," the called station starts counting zeros 100 ms after the head of a series of

zeros is detected.

If it is set to "1," the called station starts counting zeros upon detection of 10-ms successive zeros 50

ms after the head of a series of zeros is detected. In this case, if the detection of 10-ms successive

zeros is too late, the data counting period will become less than 1.0 second, making the called station

judge the line condition unacceptable.

WSW26

(Function setting 1)

Selector

No.

Function

Setting and Specifications

1

|

5

Not used.

6

7

No. of CNG cycles to be detected

(when the line is connected via the

external telephone in the external

TAD mode or via the facsimile

equipment in F/T mode)

No. 6

7

0

0

:

0.5

(A)

0

1

:

1

(B)

1

0

:

1.5

(C)

1

1

:

2

(D)

8

Not used.

NOTE:

Selectors 6 and 7 are applicable to those models equipped with a built-in TAD.

l

Selectors 6 and 7: No. of CNG cycles to be detected

The equipment interprets a CNG as an effective signal if it detects a CNG signal by the number of

cycles specified by these selectors when the line is connected via the external telephone in the

external TAD mode or via the facsimile equipment in F/T mode.

Summary of Contents for MFC-7050C

Page 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC7050C ...

Page 4: ...CHAPTER I GENERAL DESCRIPTION ...

Page 10: ...CHAPTER II INSTALLATION ...

Page 11: ...CONTENTS 1 INSTALLING THE UPDATE DATA TO THE FACSIMILE EQUIPMENT II 1 ...

Page 14: ...CHAPTER III THEORY OF OPERATION ...

Page 16: ...III 1 1 OVERVIEW ...

Page 27: ...III 12 Location of Sensors and Actuators ...

Page 30: ...III 15 ...

Page 35: ...CHAPTER IV DISASSEMBLY REASSEMBLY AND LUBRICATION ...

Page 41: ...IV 4 n n Disassembly Order Flow ...

Page 93: ...IV 56 1 33 Ink Foam 1 Take up the ink foam from the lower cover ...

Page 94: ...IV 57 1 34 Harness Routing ...

Page 96: ...IV 59 2 Control panel locks 3 Scanner frame ASSY and separation roller gear ...

Page 97: ...IV 60 4 Top cover lock spring 5 Gear plate ASSY ...

Page 98: ...IV 61 6 Hinges 7 Frame chassis ASSY ...

Page 99: ...IV 62 8 Idle pulley holder 9 Maintenance ASSY ...

Page 100: ...IV 63 10 Exit roller ASSY 11 Large feed roller ASSY ...

Page 101: ...CHAPTER V MAINTENANCE MODE ...

Page 108: ...V 6 Scanning Compensation Data List ...

Page 123: ...CHAPTER VI ERROR INDICATION AND TROUBLESHOOTING ...

Page 135: ...May 99 SM8XD115 Printed in Japan ...

Page 136: ...MFC7050C Appendix 1 EEPROM Customizing Codes ...

Page 153: ...E Power Supply PCB ...