-23-

11.

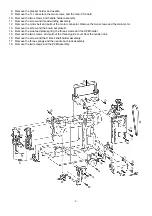

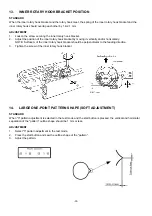

POSITION OF BUTTONHOLE SWITCH LEVER

STANDARD

When the buttonhole lever is lowered, the clearance of front part of buttonhole foot is 1.5 mm and the presser foot

lever is lowered BH 0 should touch BH 1.

ADJUSTMENT

1.

Turn on power switch and select pattern .

2.

Fit the buttonhole foot (A). Adjust the clearance to 1.5 mm,

and lower the presser foot lever.

3.

Adjust the position of buttonhole lever so that BH0 touches

BH1 when the buttonhole eccentric shaft is rotated.

NOTE: In case that the legs are shorter than the standard,

bend the BH 1 to be far from BH 0.

In case that the legs are longer than the standard,

bend the BH 2 to be close to BH 0.

12.

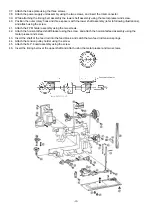

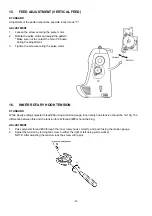

BOBBIN WINDER

STANDARD

The thread should be wound parallel to the bobbin and around about 85-

90% of the bobbin at low speed.

The clearance between the bobbin winder switch and the bobbin winder

assembly should be 0.5-1.0 mm.

ADJUSTMENT

1. Loosen the bobbin winding guide screw.

2. Adjust the bobbin thread amount so that the thread is evenly wound

around the bobbin by moving the bobbin winding guide vertically.

3. Tighten the bobbin winding guide screw.

4. Loosen the screw securing the bobbin presser slightly.

5. Turn the bobbin presser to adjust the

bobbin thread amount.

6. Tighten the screw of the bobbin presser.

7. Set the bobbin winder assembly to the left.

8. Loosen the screw of the bobbin winder

switch.

9. Adjust the clearance between the bobbin

winder switch and the bobbin winder assembly

to 0.5-1.0 mm.

10. Tighten the screw of the bobbin winder switch.

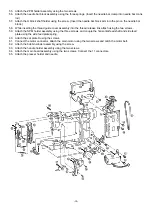

13.

INNER