-17-

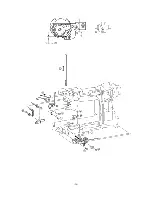

56. Attach the ZPM holder assembly using the two screws.

57. Attach the needle bar supporter assembly using the two springs. (Insert into the needle bar clamp and needle

bar crank rod)

58. Attach the needle bar supporter stud holder using the screw. (Insert the needle bar supporter arm into the pin on

the needle bar supporter.)

59. While inserting the thread guide cover assembly into the thread release link attach using the two screws.

60. Attach the SPM holder assembly using the three screws, and couple the horizontal feed plate and vertical feed

plate using the horizontal feed plate spring.

61. Attach the set plate D using the screws.

62. Connect the motor connector, attach the main motor using the two screws and catch the motor belt.

63. Attach the thread winder assembly using the screws.

64. Attach the handle holder assembly using the two screws.

65. Attach the main board assembly using the two screws. Connect the 15 connectors.

66. Attach the presser holder and needle.

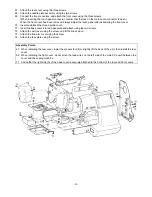

Assembly Points

56. When installing the ZPM holder assembly, the cloth selecting sensor lever should be put on the presser bar

clamp.

*

If the cloth selecting sensor lever slips down, the cloth selecting sensor cannot operate and the thread

tension cannot be adjusted.

57. Before installing the needle bar supporter assembly, insert it into the needle bar crank rod, insert the needle

bar supporter stud holder, then install a spring. Hook the longer end of the other spring (F) to the main unit.

58. Install the needle bar supporter stud holder from the needle bar supporter pin side, then attaching it using a 14

mm screw.

59. Before installing the thread guard cover, lower the presser foot lifter and move part (A) of the thread take-up

crank so that its front slants upward.

62. Apply a pressure of 200 g at the center of the motor belt, then adjust its tension until it only moves 4 to 6 mm

(B).

*

If the belt is too tight, the torque becomes too much, causing the motor to rotate slower and generate an

irregular noise. If the tension is too loose, the belt may jump and the upper shaft may not rotate smoothly

while sewing on denim and other thicker fabrics or overlapping fabrics.

63. When installing the bobbin winder assembly, align the tab (C) in the bobbin winder assembly holder with the

positioning hole in the sewing machine.

65. When installing the main PC board, insert the bottom left section of the PC board into the notch (D) in the SPM

holder assembly.

65. Insert the connectors correctly and pass the lead wires under the guides (E).

66. When installing the presser holder, install the presser foot lifter.

Summary of Contents for PC8200 SUPER GALAXIE 2000

Page 1: ...SERVICE MANUAL FOR COMPUTERIZED SEWING MACHINE PC8200 SUPER GALAXIE 2000 9 1997 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART PC 8200 Model 985 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 16: ... 14 ...

Page 18: ... 16 ...

Page 20: ... 18 ...

Page 23: ... 21 2 LEAD WIRE ARRANGEMENT PC 8200 Model 985 ...

Page 53: ... 51 Main PC board Power supply unit ...

Page 54: ... 52 LCD unit Other PC boards 985 ...

Page 55: ... 53 PC8200 SG2000 H7070093 ...