Summary of Contents for PC8200 SUPER GALAXIE 2000

Page 1: ...SERVICE MANUAL FOR COMPUTERIZED SEWING MACHINE PC8200 SUPER GALAXIE 2000 9 1997 ...

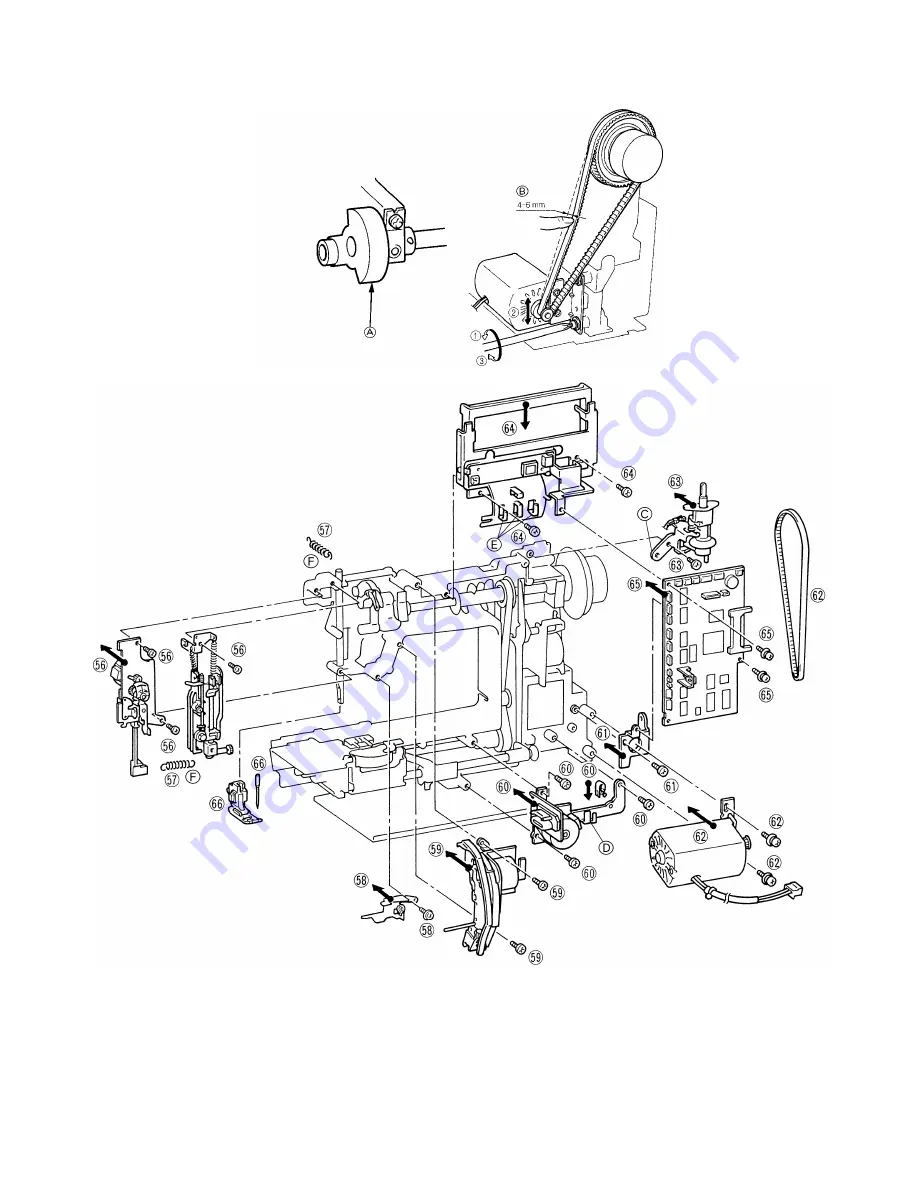

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART PC 8200 Model 985 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 16: ... 14 ...

Page 18: ... 16 ...

Page 20: ... 18 ...

Page 23: ... 21 2 LEAD WIRE ARRANGEMENT PC 8200 Model 985 ...

Page 53: ... 51 Main PC board Power supply unit ...

Page 54: ... 52 LCD unit Other PC boards 985 ...

Page 55: ... 53 PC8200 SG2000 H7070093 ...