2-7

Confidential

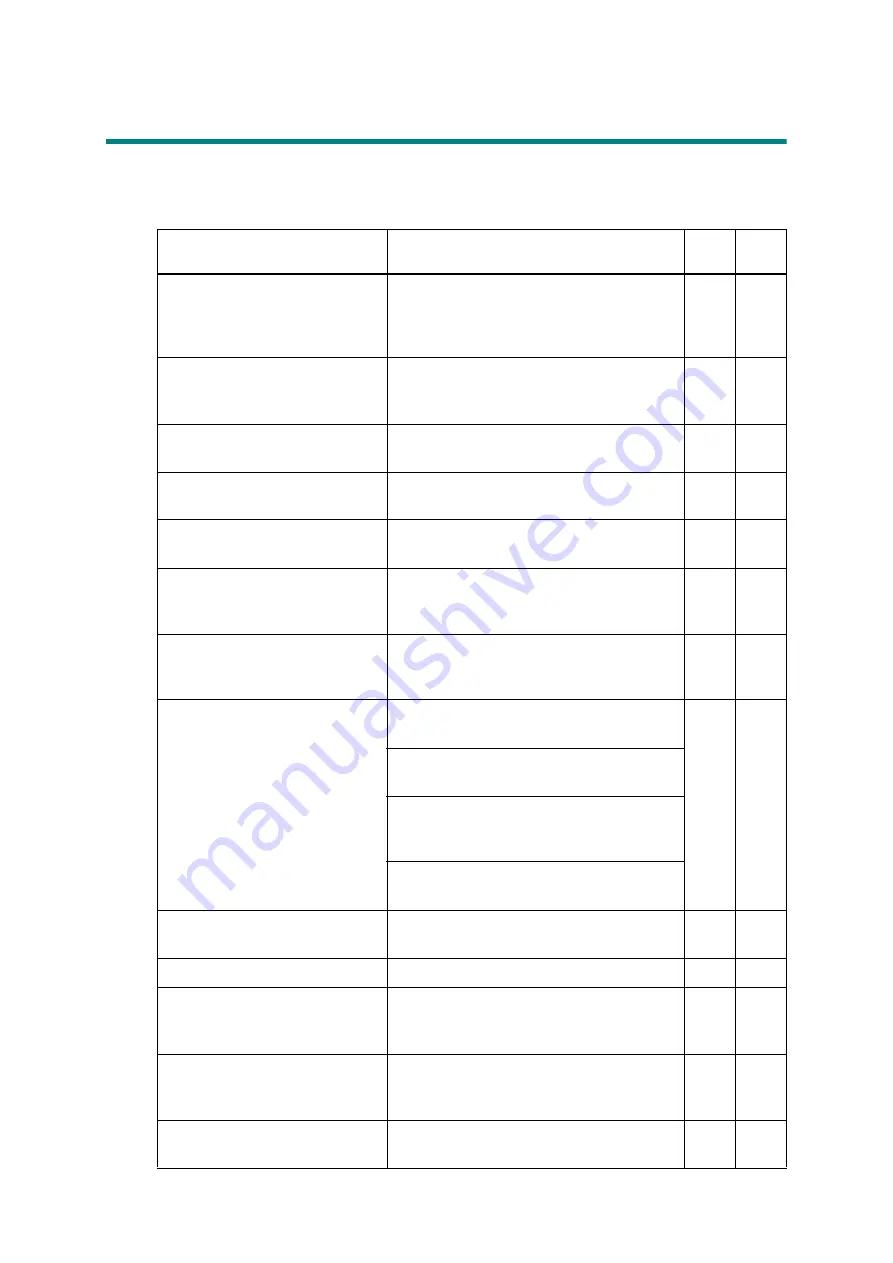

3. ERROR INDICATIONS

If the machine does not work normally it judges that an error has occurred, and indicates the

corresponding error message on the LCD, which in turn helps the service men to quickly find

out the problem.

LCD

Description

Error

codes

Refer

to:

ADF AFE LVDS test error.

When the power switch is turned ON, write

a certain value to second side LVDS

register then read again, the value is

different.

ADF AFE R/W test error.

When the power switch is turned ON, write

a certain value to second side AFE register

then read again, the value is different.

ADF cover open.

ADF cover sensor detected an open ADF

cover.

ADF front lamp error.

Light reception level of the first side CCD is

lower than the specified value.

ADF rear lamp error.

Light reception level of the second side

CCD is lower than the specified value.

AFE LVDS test error.

When the power switch is turned ON, write

a certain value to first side LVDS register

then read again, the value is different.

AFE R/W test error.

When the power switch is turned ON, write

a certain value to first side AFE register

then read again, the value is different.

Document Jam/too Long.

Scan sensor is ON when the power switch

is turned ON.

Paper jam sensor remains ON after the

specified time during document scanning.

Scan sensor detected that the smaller size

of paper was ejected during the document

feeding.

Scan sensor or paper detection sensor was

ON when the ADF cover was closed.

Document misfeed.

Paper detection sensor does not turn ON

within the specified time.

Download firmware error.

Failed to write firmware.

DRAM R/W test error.

When the power switch is turned ON, write

a certain value to DRAM then read again,

the value is different.

FlashROM R/W test error.

When the power switch is turned ON, write

a certain value to FlashROM then read

again, the value is different.

Learning error.

An error occurred when the serviceman tool

was running.

Summary of Contents for PDS-5000

Page 23: ...2 4 Confidential 2 2 Document Feed Path Fig 2 2 Front side Document feed path Back side ...

Page 45: ...3 2 Confidential 2 PACKING Fig 3 1 ...

Page 48: ...3 5 Confidential 5 LUBRICATION There are no parts that require lubrication ...

Page 49: ...3 6 Confidential 6 OVERVIEW OF GEARS Left side Fig 3 3 Right side Fig 3 4 ...

Page 138: ...5 1 Confidential CHAPTER 5 SERVICE FUNCTIONS Service mode is not equipped with this product ...