- 15 -

2.

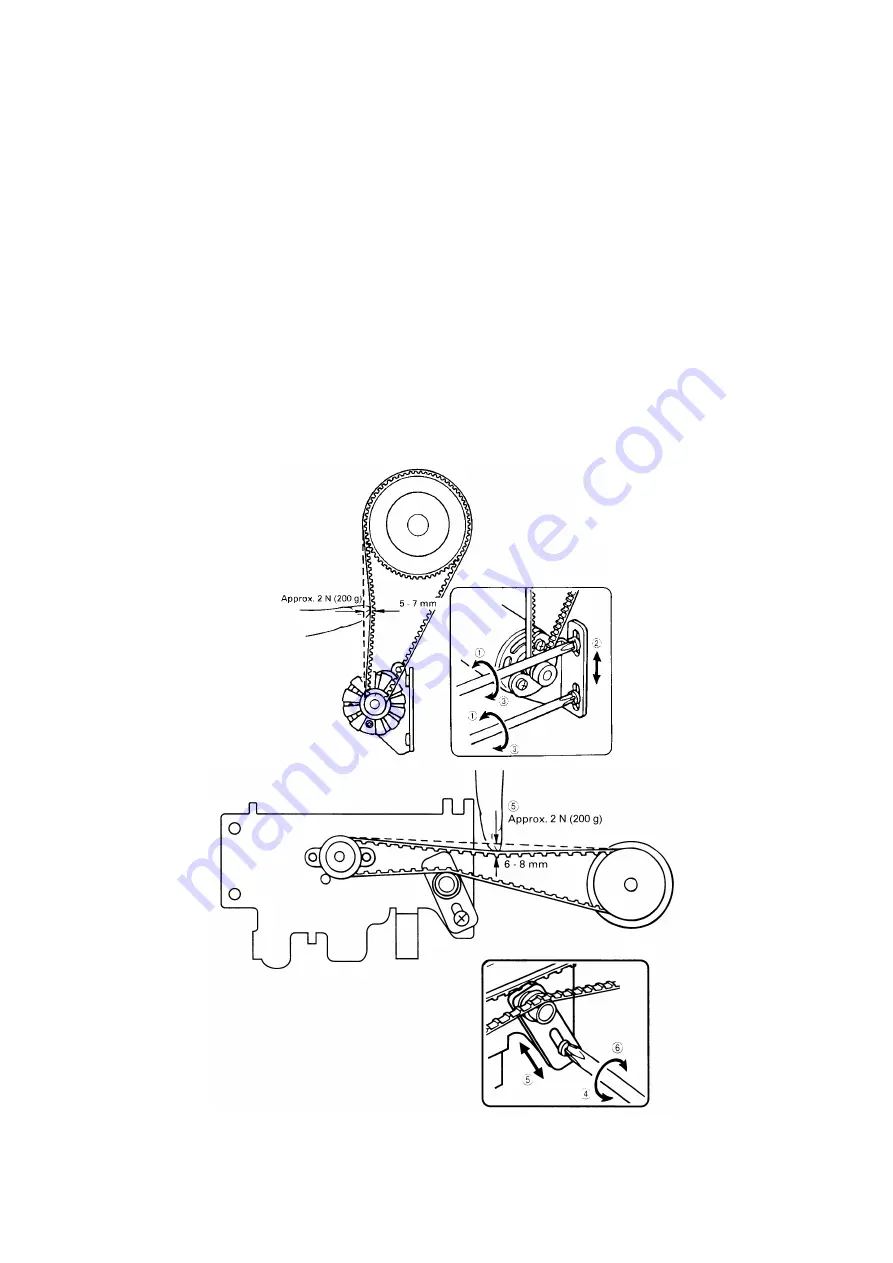

TENSION OF MOTOR DRIVE BELT AND ROTARY HOOK SHAFT BELT

STANDARD

Motor belt tension: The belt should move in by 5 - 7 mm when a force of approximately 2 N (200 g) is applied

midway between the drive pulley and motor shaft. Rotary hook shaft belt tension: The belt should move in by 6 - 8

mm when a force of approximately 2 N (200 g) is applied midway between the rotary hook shaft pulley and

vertical shaft pulley.

ADJUSTMENT

1.

Loosen the two screws of the motor holder.

2.

Move the motor holder to adjust the belt deflection to 5 - 7 mm.

3.

Tighten the two screws of the motor holder.

4.

Slightly loosen the screw of the eccentric shaft.

5.

Turn the eccentric shaft right or left to adjust the belt deflection to 6 - 8 mm.

6.

Tighten the screw of the eccentric shaft.