- 21 -

8.

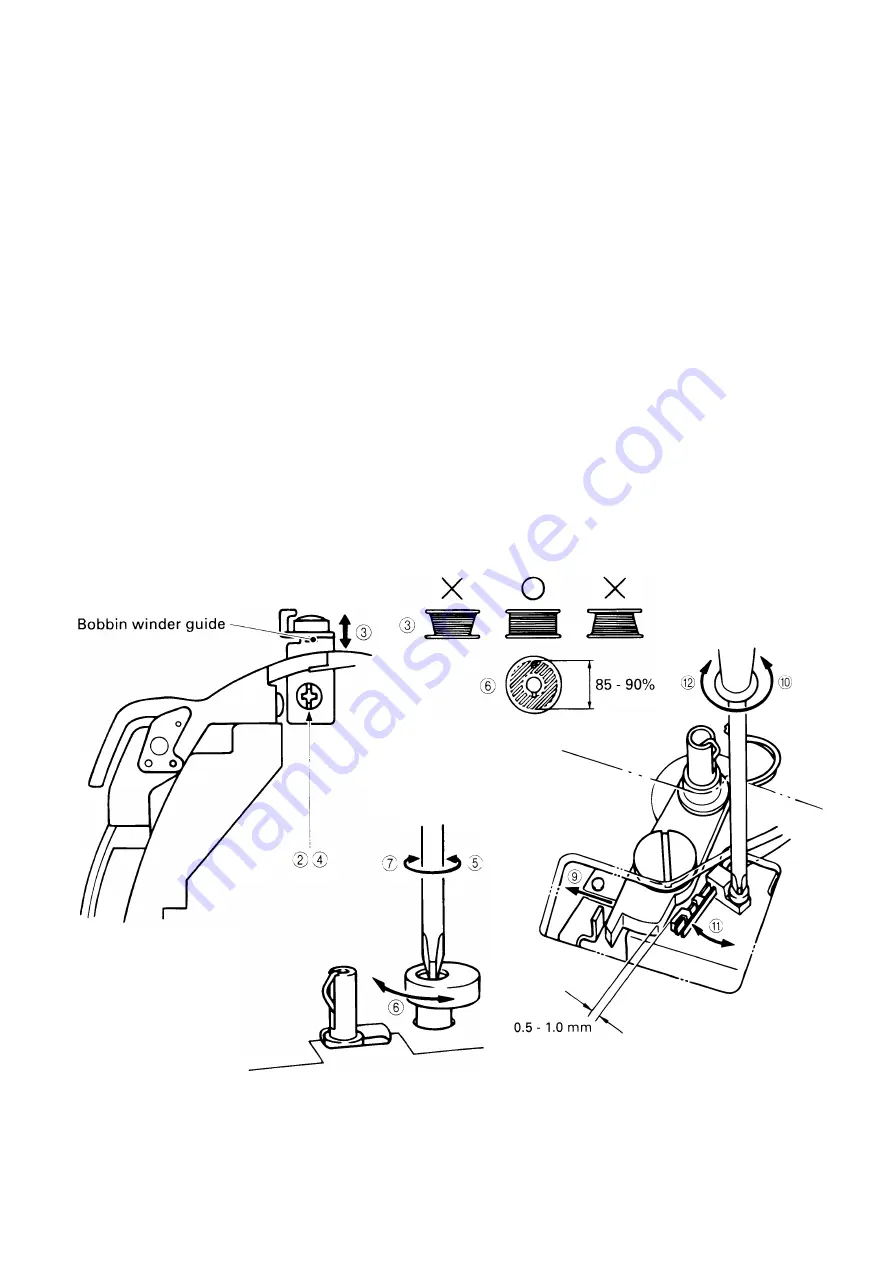

ADJUSTMENT OF BOBBIN WINDING

(ADJUSTMENT OF BOBBIN WINDER SWITCH)

STANDARD

The thread should be wound parallel to the bobbin core to 85% - 90% of the outside diameter of the bobbin.

The gap between the bobbin winder switch and the bobbin winder spindle base should be 0.5 - 1.0 mm.

ADJUSTMENT

1.

Remove the face plate. (Refer to page 9.)

2.

Loosen the screw of the bobbin winder guide.

3.

Adjust the bobbin winding by moving the bobbin winder guide.

4.

Tighten the screw of the bobbin winder guide.

5.

Slightly loosen the screw of the bobbin presser.

6.

Turn the bobbin presser to adjust the bobbin winding amount.

7.

Tighten the screw of the bobbin presser.

8.

Remove the rear cover. (Refer to page 9.)

9.

Set the bobbin winder spindle to the left and turn the bobbin winder switch off.

10. Loosen the screw of the bobbin winder switch.

11. Adjust the gap between the bobbin winder switch and bobbin winder spindle base to 0.5 - 1.0 mm.

12. Tighten the screw of the bobbin winder switch.