- 33 -

20.

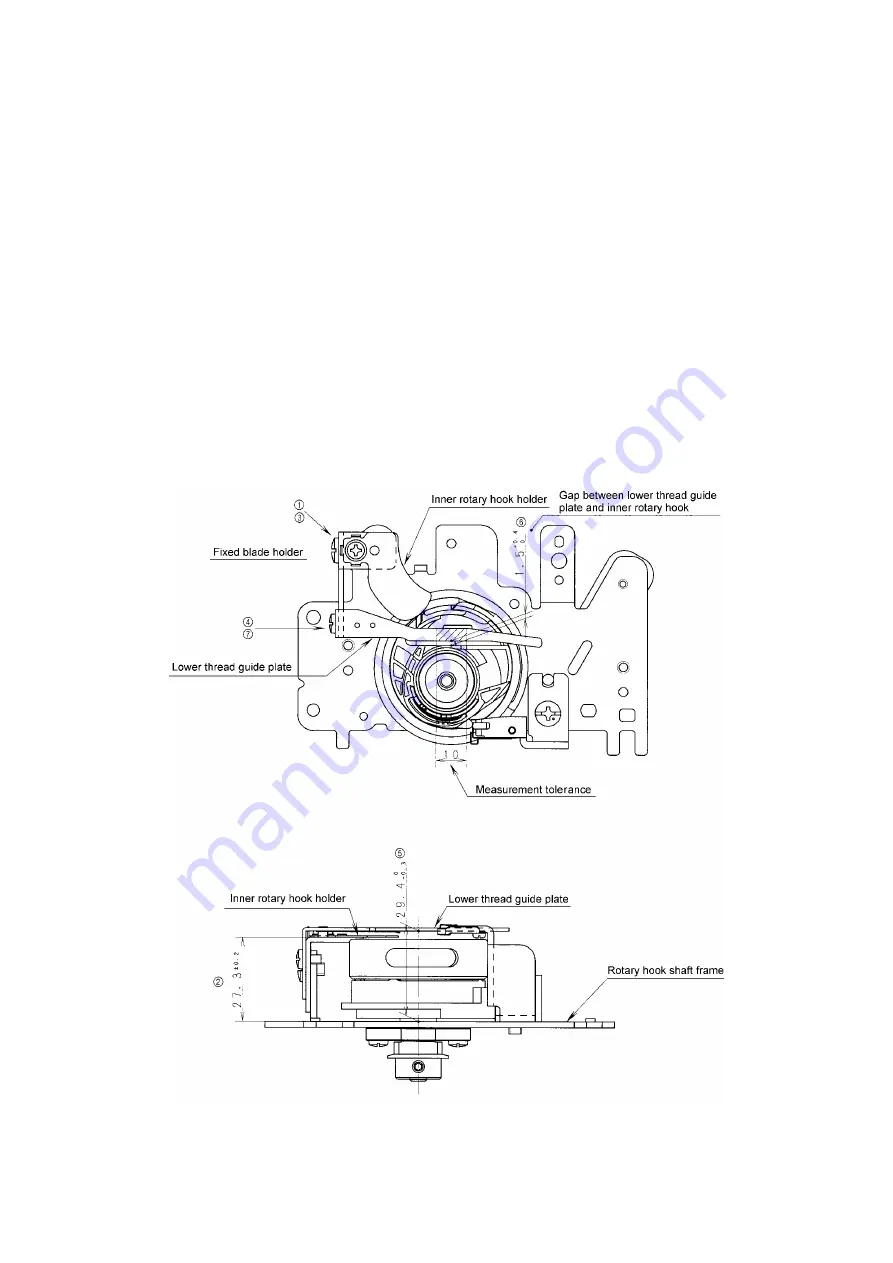

ADJUSTMENT OF INNER ROTARY HOOK HOLDER AND LOWER THREAD

GUIDE PLATE

STANDARD

•

The inner rotary hook holder should be 27.3±0.2 mm above the rotary hook shaft frame.

ADJUSTMENT

1.

Loosen the mounting screw of the fixed blade holder.

2.

Move the inner rotary hook holder so that it is 27.3±0.2 mm above the rotary hook shaft frame.

3.

Tighten the mounting screw of the fixed blade holder.

•

The lower thread guide plate should be 29.4 mm above the rotary hook shaft frame. In addition, the gap

between the lower thread guide plate and inner rotary hook should be 1.5 mm.

4.

Loosen the mounting screw of the lower thread guide plate.

5.

Move the lower thread guide plate so that it is 29.4 mm above the rotary hook shaft frame.

6.

Move the lower thread guide plate so that it is 1.5 mm from the inner rotary hook.

7.

Tighten the mounting screw of the lower thread guide plate.

0

- 0.3

+ 0.4

0

0

- 0.3

+ 0.4

0