- 31 -

4.

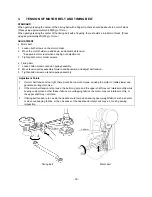

TIMING OF ROTATION SHUTTER AND UP-DOWN FEED CAM

STANDARD

When needle bar is in highest position, foundation hole of vertical shaft pulley should be facing front of sewing

machine.

At this time, base line of outer rotary hook pulley should also be facing front of sewing machine.

Phases of base line of rotation shutter even with screw hole and foundation hole of vertical shaft pulley should be

the same.

ADJUSTMENT

•

Vertical shaft and outer rotary hook pulleys

1.

Position so that base lines of vertical shaft and outer rotary hook pulleys are facing front of sewing machine.

Attach timing belt.

2.

Loosen both screws of the upper shaft gear.

3.

Turn pulley to raise needle bar to its uppermost position.

4.

Make sure that vertical shaft and outer rotary hook pulleys are positioned as indicated in 1. Then tighten both

upper shaft gear screws.

* After completing adjustments, make absolutely sure to check the backlash of the upper and vertical shaft

gears.

•

Rotation shutter

1.

Loosen rotation shutter screw.

2.

Adjust phases of base line of rotation shutter even with screw hole and foundation hole of vertical shaft

pulley.

3.

Tighten rotation shutter screw.

* Use only 2-4kg-cm of torque when tightening rotation shutter screw. Applying too much pressure could

wear out grooves in top of screw, making it impossible to fasten securely.

base line

foundation

hole

base line

Summary of Contents for PE-300S

Page 1: ... 2 1999 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART ...

Page 7: ... 5 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 11: ... 9 9 1 1 9 9 8 7 7 3 3 6 6 2 2 3 1 1 9 5 5 5 ...

Page 13: ... 11 12 11 17 20 20 15 16 19 20 18 13 14 10 10 ...

Page 15: ... 13 25 2 25 1 23 36 29 29 37 32 22 22 24 24 27 27 30 30 31 31 33 33 34 32 28 36 35 26 ...

Page 17: ... 15 39 39 38 ...

Page 19: ... 17 Diagram A 45 1 45 2 42 53 48 52 49 50 43 42 41 44 47 47 46 40 51 ...

Page 21: ... 19 Diagram A 55 60 56 54 58 64 64 65 61 61 59 59 54 57 ...

Page 23: ... 21 diagram A 74 69 69 68 69 75 73 72 70 67 67 ...

Page 25: ... 23 77 78 84 68 84 78 78 79 86 86 84 ...

Page 27: ... 25 5 3 2 2 2 2 3 4 1 5 ...

Page 28: ... 26 3 LEAD WIRE ARRANGEMENT ...

Page 57: ...PE 300S H8080132 ...