EMBROIDERING TUTORIAL

———————————————————————————————————————————————————

26

5. Specifying Embroidering Setting

When

in the pattern editing screen is touched, the embroidering settings screen appears. From this

screen, the entire pattern can be edited and embroidering settings can be specified. In addition, the

embroidering position can be checked and a pattern can be saved for later use.

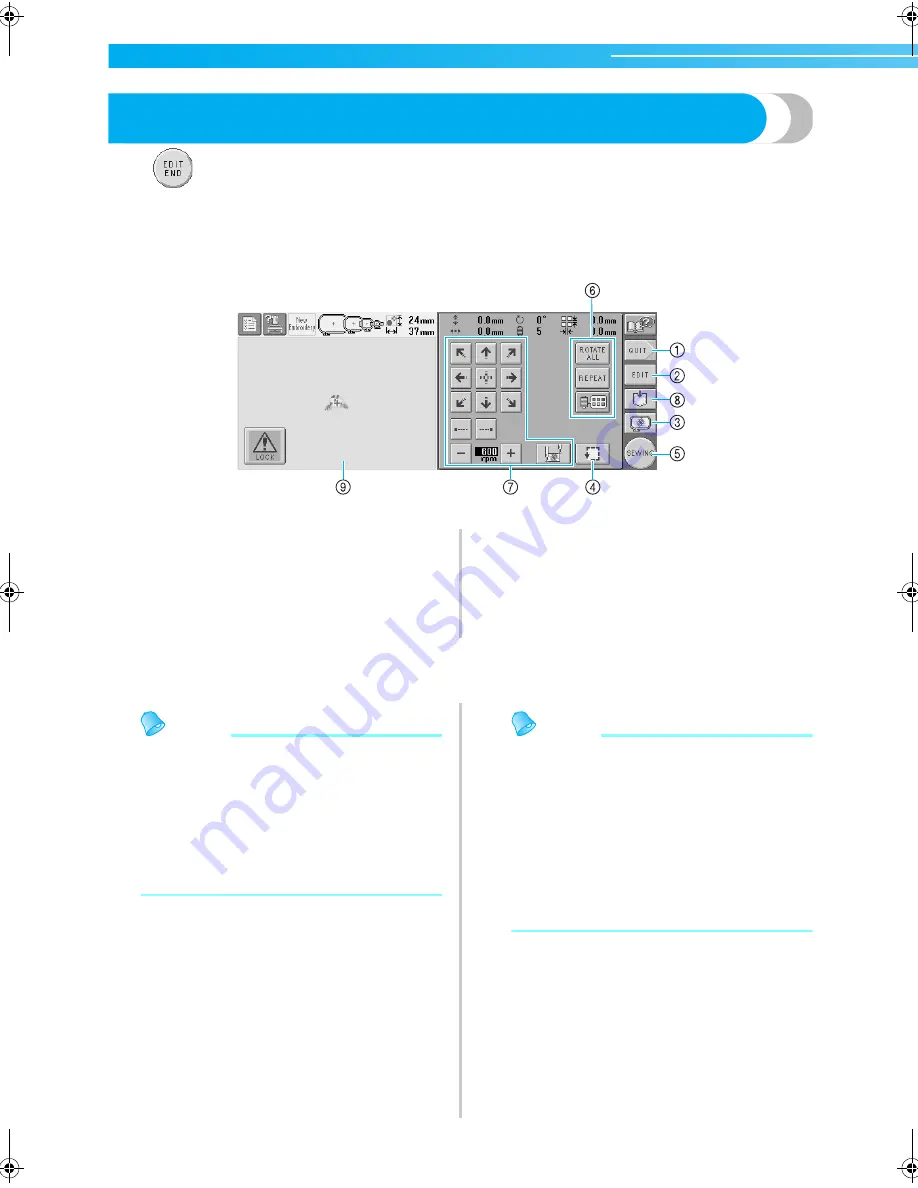

Embroidering settings screen

(For details on the keys and other information on the screen, refer to page 54.)

1

Restarts from the beginning

2

Returns to the pattern editing screen

3

Displays a preview image

4

Touch to check the embroidering area.

5

Continues to the next screen

6

Touch to edit the pattern.

7

Touch these keys to specify how the pattern will

be embroidered.

8

Touch to store the pattern.

9

In the embroidering settings screen, the

embroidery frame guide in the pattern display

area indicates the size of the installed embroidery

frame.

In this example, we will not specify any of the embroidering settings. Continue with the next operation.

Memo

●

If the embroidery frame is not positioned

correctly when continuing to the

embroidering settings screen, the

embroidery frame is moved to the correct

position at the same time that the

embroidering settings screen is displayed.

(Refer to “Embroidery Frame Position and

Movement” on page 70.)

Memo

●

If an operation in the embroidering settings

screen is interrupted and the machine is

turned off, the operation can be continued

after the machine is turned on again. When

the machine is turned on again, you will be

asked if you wish to continue the previous

operation or begin a new one. (Refer to

“Resume the Operation Being Performed

Before the Machine Was Turned OFF” on

page 62.)

Sapphire_brother.book Page 26 Thursday, November 17, 2005 2:48 PM

Summary of Contents for PR-600II

Page 1: ...EMBROIDERY MACHINE PR 600 O P E R A T I O N M A N U A L ...

Page 77: ...EMBROIDERING TUTORIAL 60 ...

Page 115: ...EMBROIDERING SETTINGS 98 ...

Page 171: ...BASIC SETTINGS AND HELP FEATURE 154 ...

Page 229: ...APPENDIX 212 ...

Page 236: ...Index 219 7 ...

Page 237: ......