7

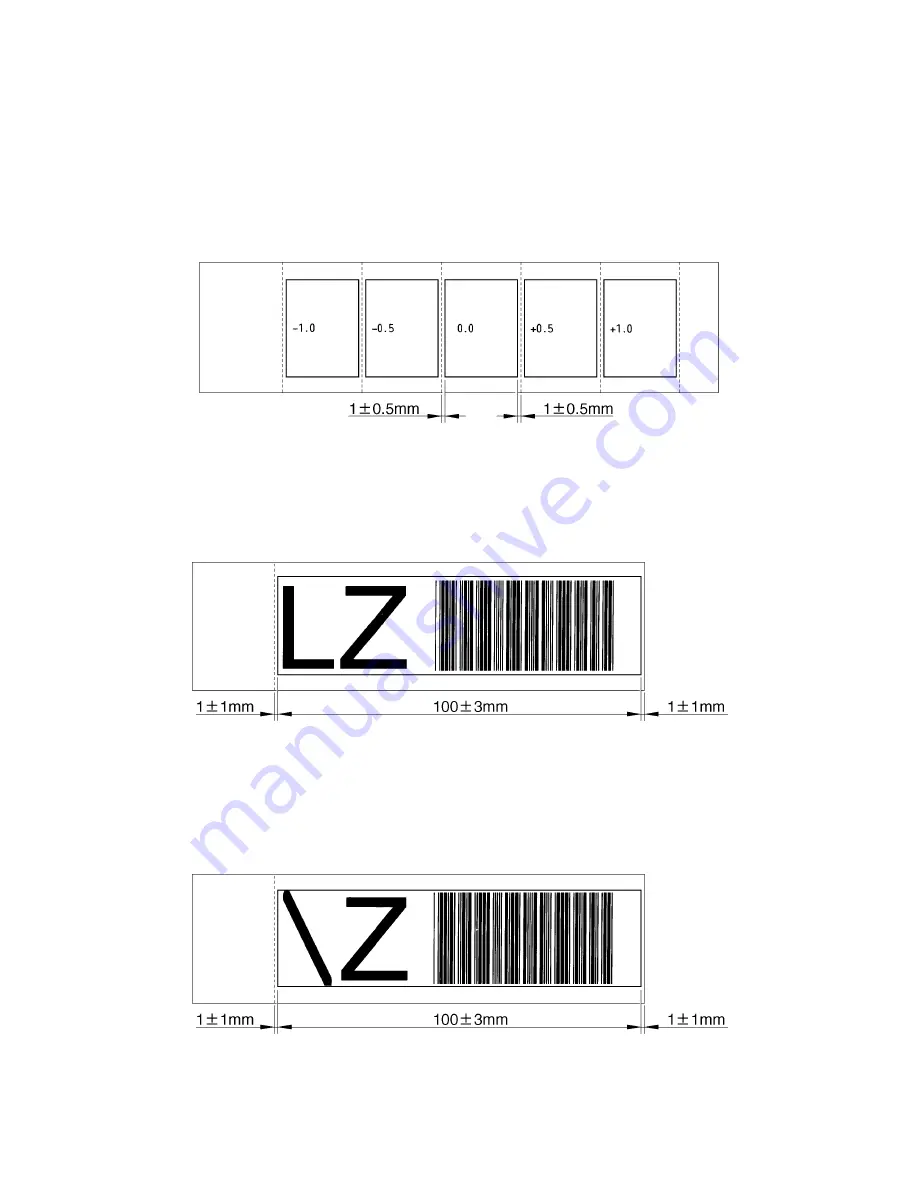

(14) E. Adjustment of half cut margins

* This mode is to adjust each margin amount of right and left ends to

±

0.5mm.

1) Mount the 36mm laminated tape cassette in the PT-9500PC and run the half cut operation

shifting the margins of both ends by 0.5mm from -1mm to +1mm.

2) Check that the sample result of half cut operation is proper. Then determine the position

where the margins at both ends are close to even.

3) Input the compensation value and click the OK button.

4) Check that each margin mount of both ends on the second sample printing is 1

±

0.5mm.

Fig. 7

(15) G. HG speedy printing (Skip this item if U.S.A. version.)

1) Mount the 36mm HG cassette in the PT-9500PC and run the HG speedy printing operation.

2) Check the printing length, the front and back margins and the printing quality of the printing

sample.

Fig. 8

(16) H. HG high resolution printing test (Skip this item if U.S.A. version.)

1) Mount the 36mm HG cassette in the PT-9500PC and run the HG high resolution printing

operation.

2) Check the printing length, the front and back margins and the printing quality of the printing

sample.

Fig. 9

Summary of Contents for PT-9500PC - P-Touch 9500pc B/W Thermal Transfer Printer

Page 1: ...SERVICE MANUAL MODEL PT 9500PC ...

Page 2: ...SERVICE MANUAL MODEL PT 9500PC ...

Page 86: ...IV 10 3 The LED does not turn on 4 No printing is performed ...

Page 87: ...IV 11 5 The interface malfunction 6 The tape is not cut ...

Page 88: ...IV 12 7 The tape is not fed correctly ...

Page 89: ...IV 13 ...

Page 90: ...IV 14 8 Half cut failure ...

Page 91: ...IV 15 9 Forced tape eject failure ...

Page 92: ...IV 16 10 The failure of pressure contact release of the roller holder ...

Page 103: ......

Page 104: ......

Page 105: ......