4. ADJUSTMENT

RH-981A

52

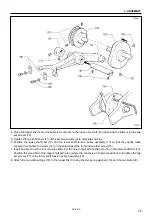

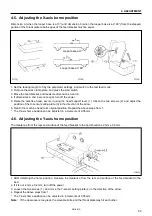

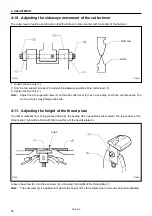

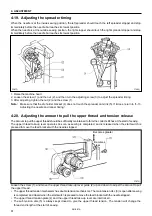

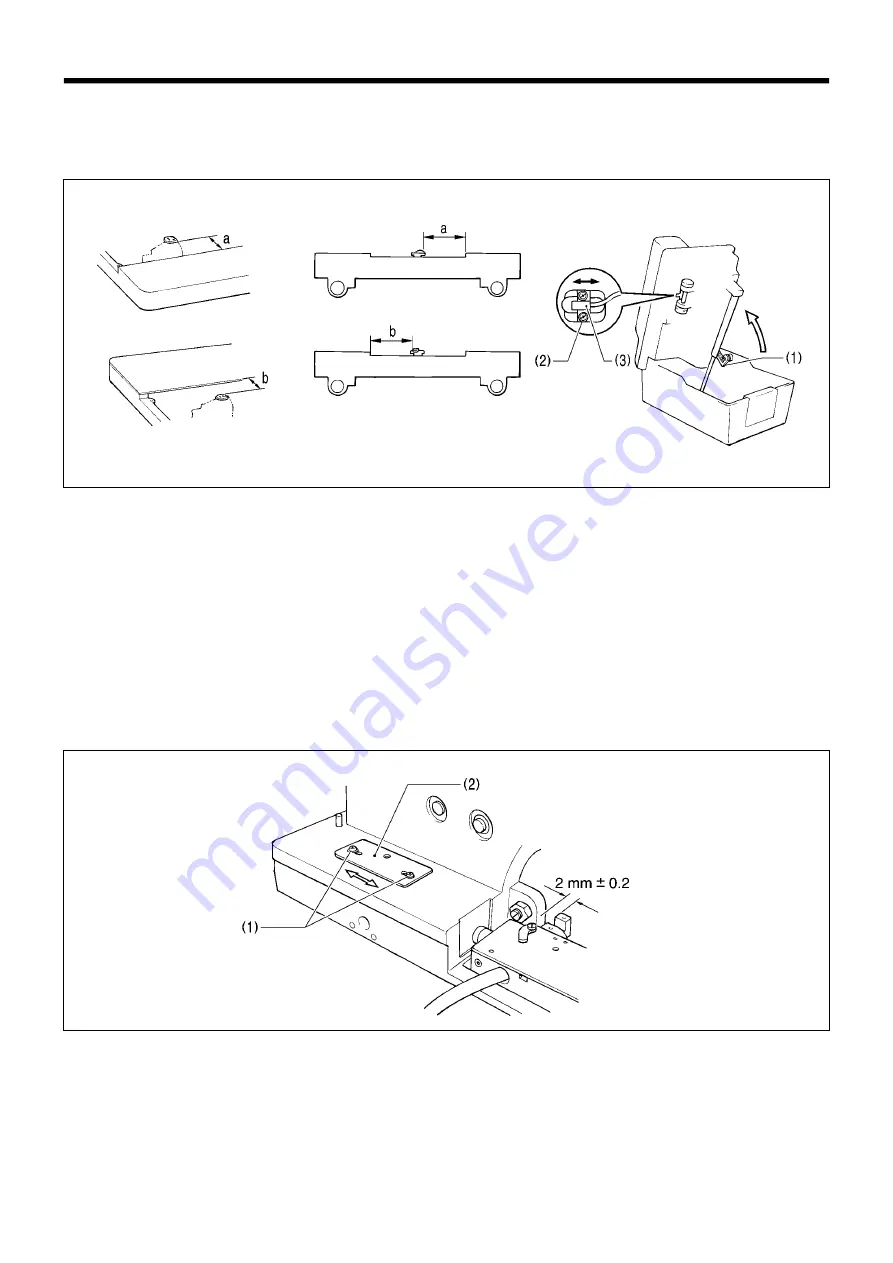

4-5. Adjusting the X-axis home position

Dimension a (when the looper base is at 0°) and dimension b (when the looper base is at 180°) from the stepped

portion of the throat plate to both edges of the feed bracket must be equal.

1. Set the tacking length to 0 by the parameter settings, and switch to the test feed mode.

2. Remove the work clamp plate, and press the start switch.

3. Move the feed bracket, and measure dimensions a and b.

4. If dimensions a and b are not equal, turn off the power.

5. Raise the machine head, secure it using the head support lever (1), loosen the two screws (2), and adjust the

position of the X-sensor setting plate (3) in the direction of the arrow.

6. Return the machine head to its original position. Repeat the above steps from 1.

* The X-axis home position can be adjusted in increments of 0.05 mm.

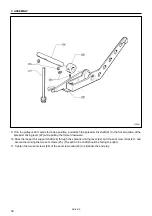

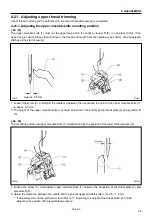

4-6. Adjusting the Y-axis home position

The clearance from the rear end surface of the feed bracket to the bed should be 2 mm ± 0.2 mm.

1. After detecting the home position, measure the clearance from the rear end surface of the feed bracket to the

bed.

2. If it is not 2 mm ± 0.2 mm, turn off the power.

3. Loosen the two screws (1), and move the Y-sensor setting plate (2) in the direction of the arrow.

4. Repeat the above steps from 1.

* The Y-axis home position can be adjusted in increments of 0.05 mm.

Note:

If the clearance is too great, the movable knife and the throat plate may hit each other.

3779Q

3777Q

3778Q

Looper base at 180°

Looper base at 0°

3780Q