4. ADJUSTMENT

RH-981A

73

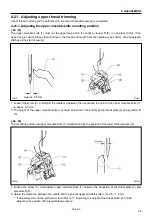

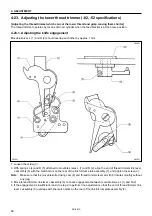

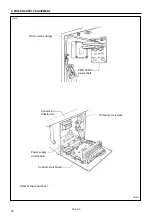

4-23-6. Adjusting the auxiliary clamp arm

The auxiliary clamp arm holds the material until the lower thread and the gimp are trimmed after the work clamp

rises.

The auxiliary clamp arm should be adjusted so that it can operate when the feed bracket is at the home position, and

will be stationary on the needle plate without subjecting it to any pressure.

1. Loosen the bolt (1), and position the auxiliary clamp arm (2) on the needle plate so that the auxiliary clamp arm

(2) can hold the material next to work clamp.

Note:

Be sure that the auxiliary clamp arm (2) does not make contact with clamp arm L-J (3).

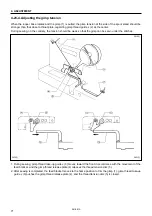

2. Turn on the power to set the home position.

3. Turn off the air, and loosen the two screws (4).

4. With the rod of the auxiliary clamp arm cylinder (5) fully extended, adjust so that the auxiliary clamp arm (2) can

be stationary to the needle plate without subjecting it to any pressure.

Note:

If excessive pressure is applied to the auxiliary clamp arm when the feed bracket is at the home position,

the feed bracket may be in an inappropriate position in the Y direction.

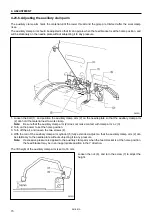

The lift height of the auxiliary clamp arm is set to 16 mm.

Loosen the nut (6), and turn the screw (7) to adjust the

height.

3824Q

3825Q