7. ADJUSTMENTS

S-7300A

114

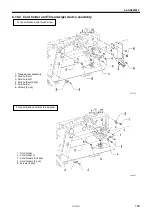

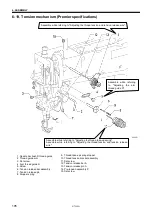

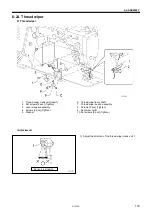

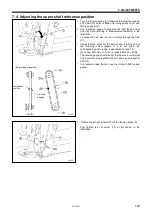

7-1. Thread tension spring

<Thread tension spring position>

The standard position of the thread take-up spring (1) is 6 to

7 mm (for -3 specifications) or 4 to 5 mm (for -5

specifications) above the surface of the arm thread guide (3)

when the presser foot (2) is lowered.

1.

Lower the presser foot (2).

2. Loosen the set screw (4).

3. Turn the thread tension bracket (5) to adjust the spring

position.

4. Securely tighten the set screw (4).

*

If the lifting lever or other method has been used to raise

the presser foot when adjusting the thread take-up spring,

the movement amount of the thread take-up spring will be

limited by the thread take-up spring stopper.

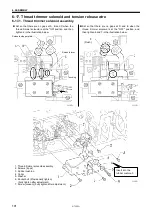

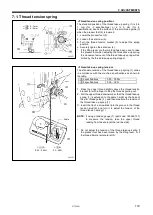

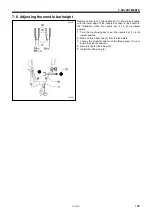

<Thread take-up spring tension>

The standard tension of the thread take-up spring (1) varies

in accordance with the machine specifications as shown in

the table.

-[][]3 specifications

0.25 - 0.35N

-[][]5 specifications

0.30 - 0.5N

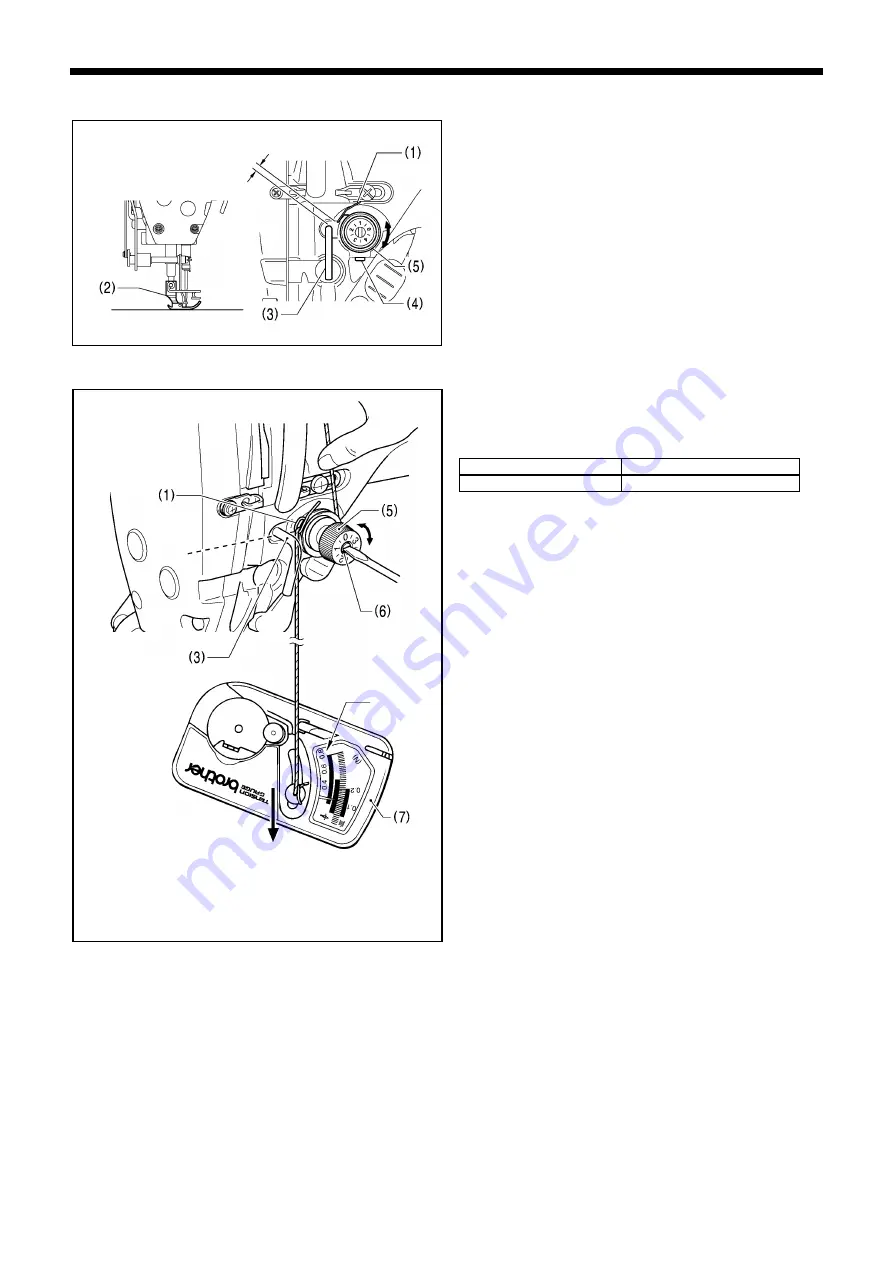

1.

Press the upper thread slightly above the thread tension

bracket (5) with a finger to stop the thread spooling out.

2.

Pull the upper thread downward so that the thread take-up

spring (1) is extended to the same height as the base of

the arm thread guide (3), and then measure the tension of

the thread take-up spring (1).

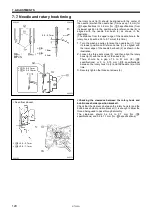

3.

Insert the tip of a screwdriver into the groove in the thread

tension stud (6) and turn it to adjust the tension of the

thread tension spring (1).

NOTE:

If using a tension gauge (7) (part code: 183922-101)

to measure the tension, take the upper thread

reading from the scale [at the red line side].

*

Do not adjust the tension of the thread take-up spring if

the presser foot has been raised by the lifting lever, or if

the thread trimmer solenoid is ON.

0912D

<-[][]3> 6 - 7mm

<-[][]5> 4 - 5mm

0913D

Scale

<-[ ][ ]5>

0.3 - 0.5N

<-[ ][ ]3>

0.25 - 0.35N