S-7300A

11. TROUBLESHOOTING

177

Problem

Possible cause

Page

10 Upper and lower threads

are breaking.

・

Is the needle tip bent? Is the needle tip blunt?

If the needle tip is bent or blunt, replace the needle.

・

Is the needle properly installed?

If it is incorrect, install the needle correctly.

・

Is the machine properly threaded?

If it is incorrect, thread the thread correctly.

・

Is the rotary hook sufficiently lubricated?

If the oil gauge is down to the lower reference line in the oil

gauge window, add more oil.

・

Is the upper or lower thread tension too weak or too strong?

Adjust the upper thread or lower thread tension.

・

Is the upper thread may be loose because the thread take-up spring

operating range is too small?

Adjust the position of the thread take-up spring.

・

Is the rotary hook, feed dog or other part damaged?

If the thread path is damaged, smooth it with sandpaper or

similar.

Alternatively, replace the damaged part.

・

Is the thread path damaged?

If the thread path is damaged, smooth it with sandpaper.

Alternatively, replace the damaged part.

Instruction

manual

Instruction

manual

Instruction

manual

Instruction

manual

114*

Instruction

manual

Instruction

manual

11 Thread breaks during

backtack sewing.

・

Is the backtack sewing speed too fast?

Use the panel to reduce the backtack sewing speed.

Instruction

manual

12 Backtack sewing pitch

varies depending on the

sewing direction.

Backtack edge is not

aligned.

Adjust using MSW-201.

11*

13 Thread tightening around

X-over seam areas.

・

Is the height of the feed dog correct?

Increase the feed dog height.

122*

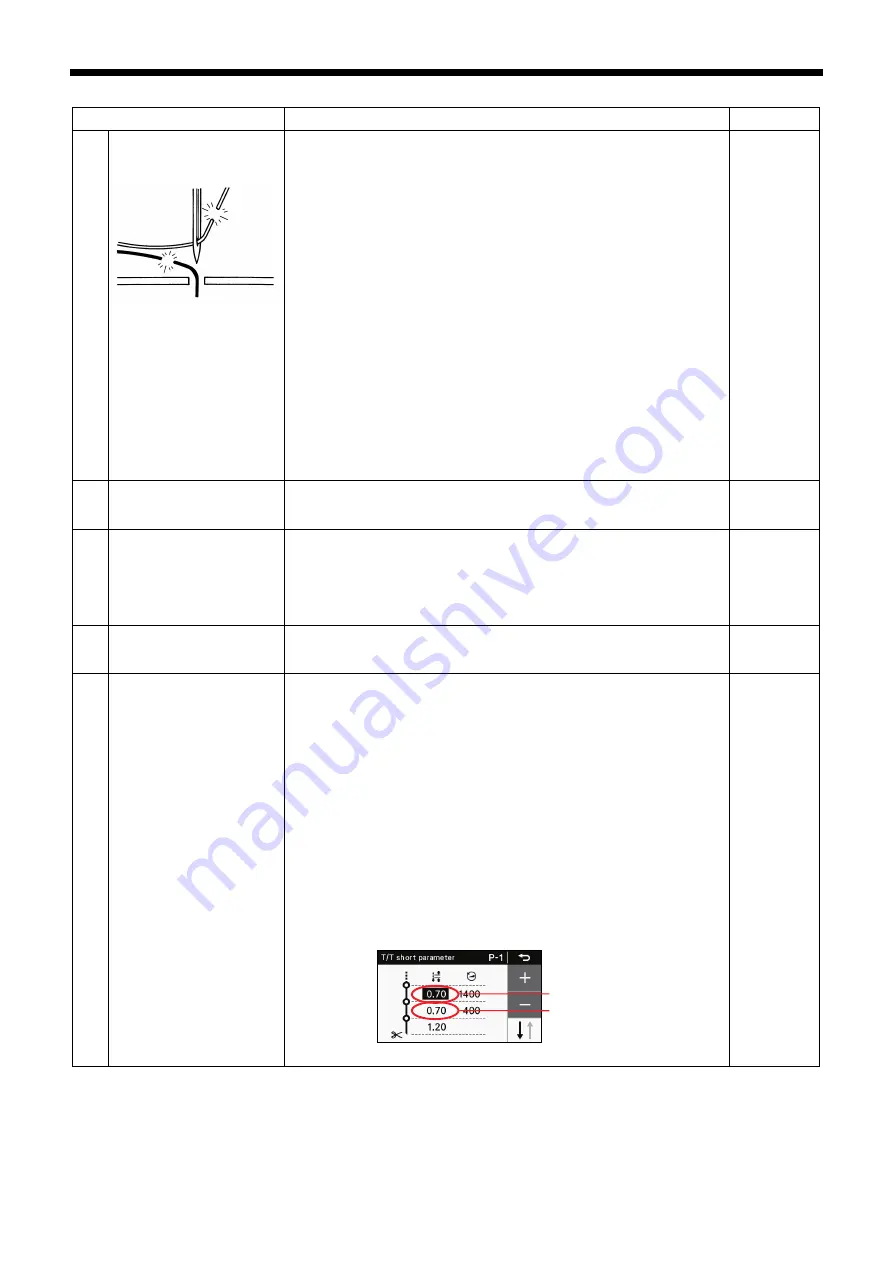

14 Upper thread is pulling out

of the needle after thread

trimming.

・

Is the upper thread trailing length after thread trimming appropriate?

Decrease the tension of the pre-tension.

・

Is the thread path not smooth enough?

Use a file with a fine grain or sandpaper to polish smooth the

thread path.

・

Does the thread being used slip easily?

Turn the needle bar bush thread guide D sideways to increase

the resistance.

・

If the upper thread is pulling out of the needle after thread trimming,

check using the method given below.

1. Check the upper thread trailing length.

2. Re-adjust the upper thread trailing length to make it longer.

3. Keep pressing the best PFM mode key, and then select "T/T

short parameter".

(1) Delete the stitch pitch for the previous stitch.

(2) Decrease the sewing speed for the final stitch and the

stitch before it.

135

・

136

Instruction

manual

Instruction

manual

Stitch pitch for 1st stitch

Stitch pitch for 2nd stitch

0471M