19

c

Touch the “Start” key to start cutting.

Memo

• When the roll feeder is used, half-cutting is automatically

turned on.

When cutting is finished, the following screen appears.

Check the results of trial cutting.

For details, see “Checking the Trial Cutting Results” on page 19.

• To start cutting the pattern for your project, press the “Start”

key.

When cutting is finished, see step

• To perform trial cutting again, press the “Test again” key.

For details, see “Changing the Cut Pressure Setting” on

page 19.

• To perform trial feeding, press

.

For details, see “Trial Feeding” on page 20.

■

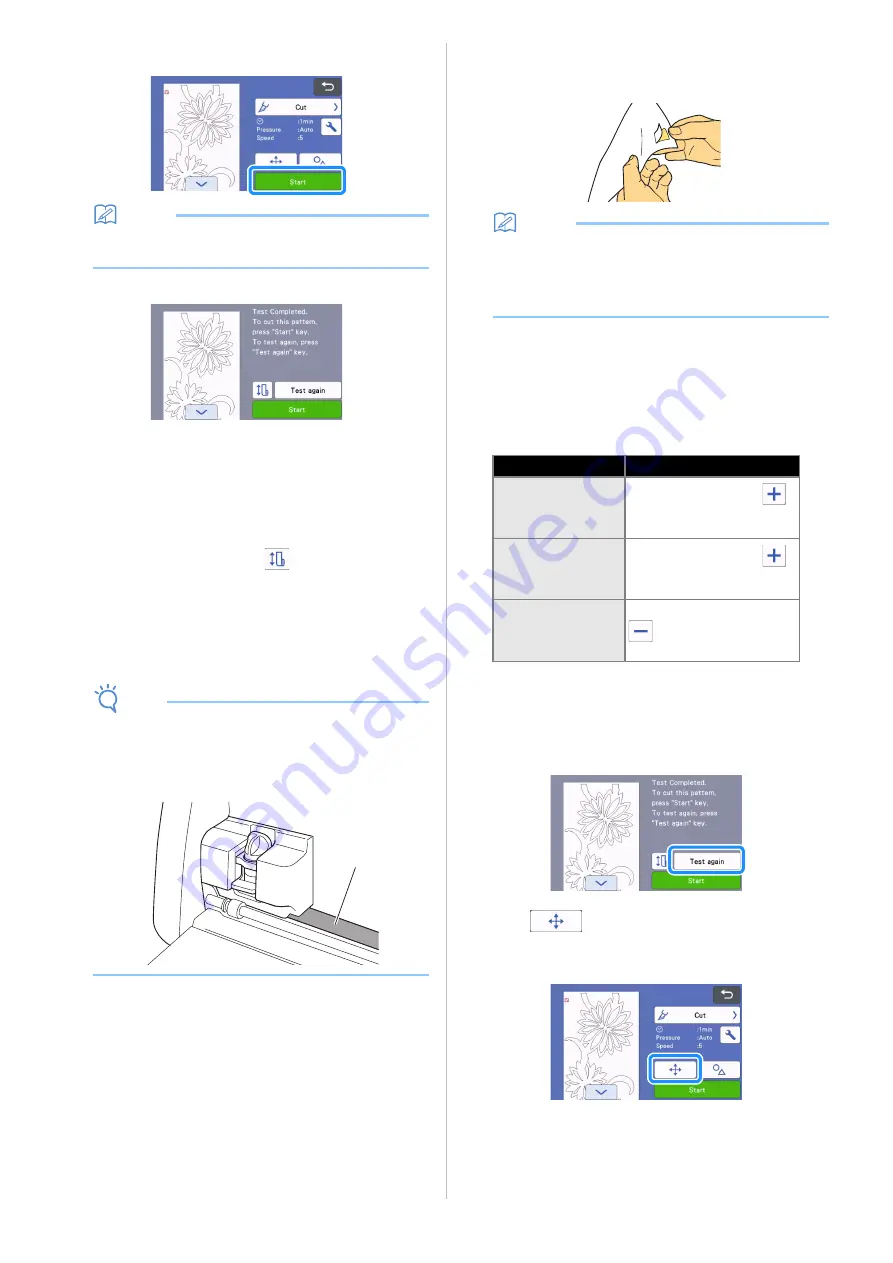

Checking the Trial Cutting Results

Adjust the cutting pressure according to the trial cutting results.

Repeatedly perform trial cutting and adjust the cutting pressure until

the material is cut cleanly.

Note

• If the blade penetrates the material, faint cut marks may

remain on the machine's surface where the blade makes

contact (

1

). In that case, cutting may no longer be

performed correctly. Contact Brother Customer Service or

Brother authorized service center.

Appropriate cutting pressure

The appropriate cutting pressure is when the surface layer of

the material is cut cleanly and the backing paper is not cut.

Memo

•

The hook of the spatula and hook set (CASPHK 1) is useful

for peeling off the half-cut material from the backing paper

or backing film. To purchase the spatula and hook set

(CASPHK 1), contact the retailer where this product was

purchased.

■

Changing the Cut Pressure Setting

The appropriate cutting pressure for half-cuts is automatically set;

however, some types of material may not be cut cleanly.

If the material could not be cut cleanly, refer to the following table,

and adjust the setting for the cutting pressure. Since the blade may

penetrate the material, perform trial cutting after each time that the

setting is increased.

Changing the cut pressure setting

a

When the following screen appears after trial cutting is

finished, touch the “Test again” key to display the test

screen.

b

Touch

to move the test pattern to a different

location. The test pattern can also be moved by dragging

it in the screen.

a

Trial cutting result

Adjustment

Part of the pattern is

not cut.

Pressure too light: Touch

in the settings screen once to

increase the pressure.

The entire pattern is

not cut.

Pressure too light: Touch

in the settings screen once to

increase the pressure.

There are deep cuts

completely through

the backing paper.

Pressure too strong: Touch

in the settings screen once

to decrease the pressure.

Summary of Contents for ScanNCut DX

Page 1: ...Roll Feeder ...

Page 38: ...English Version A ...