-43-

15.

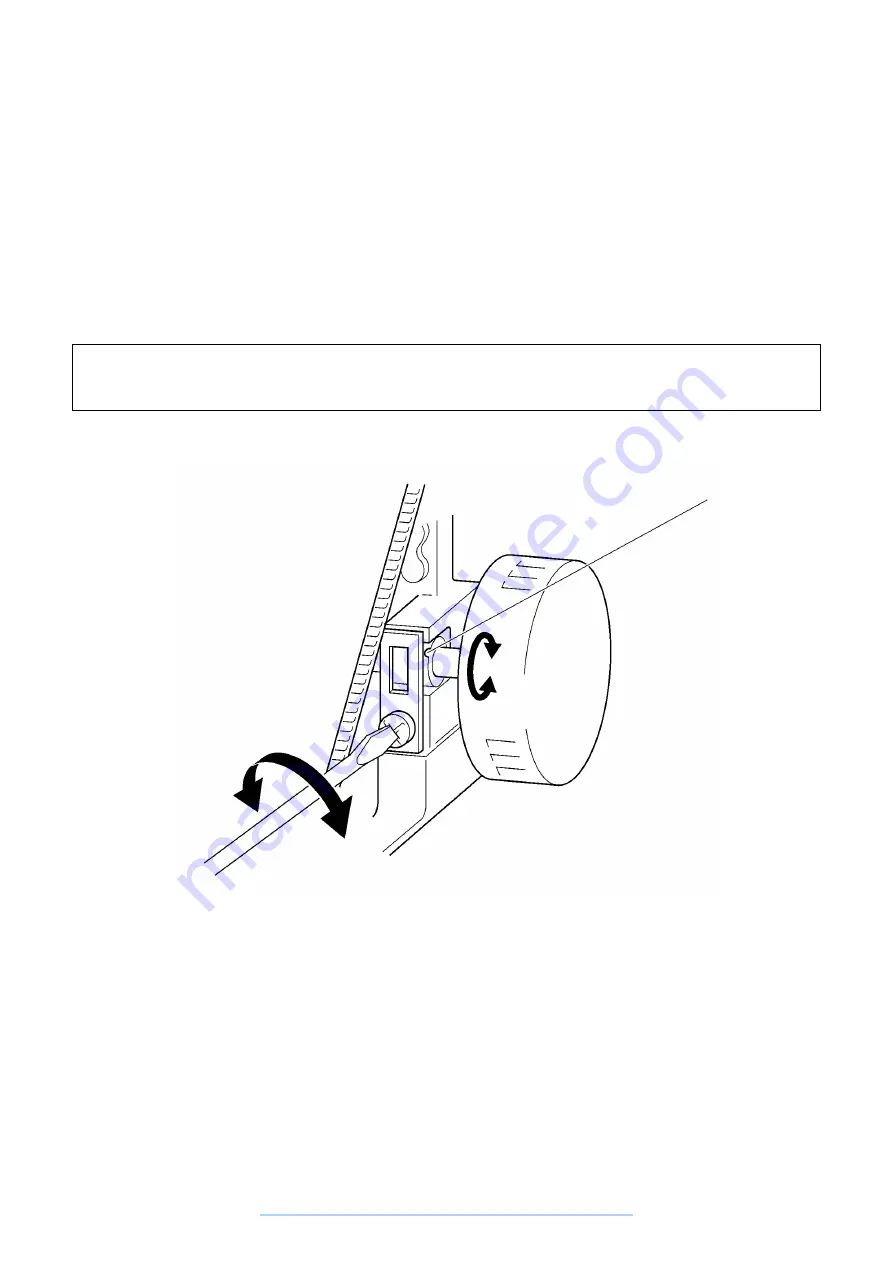

SELECTION DIAL OUTER EDGE PLAY

STANDARD

The selection dial outer edge play should be 0.5-2 mm.

ADJUSTMENT

1.

Loosen the screw securing the presser plate.

2.

Rotate the selection dial bearing to adjust the play.

3.

Tighten the screw securing the presser plate.

Adjustment Points

2.

Turning the selection dial bearing so that the alignment mark is up reduces play; turning it so that it is

down increases play.

Alignment mark

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...