-51-

23.

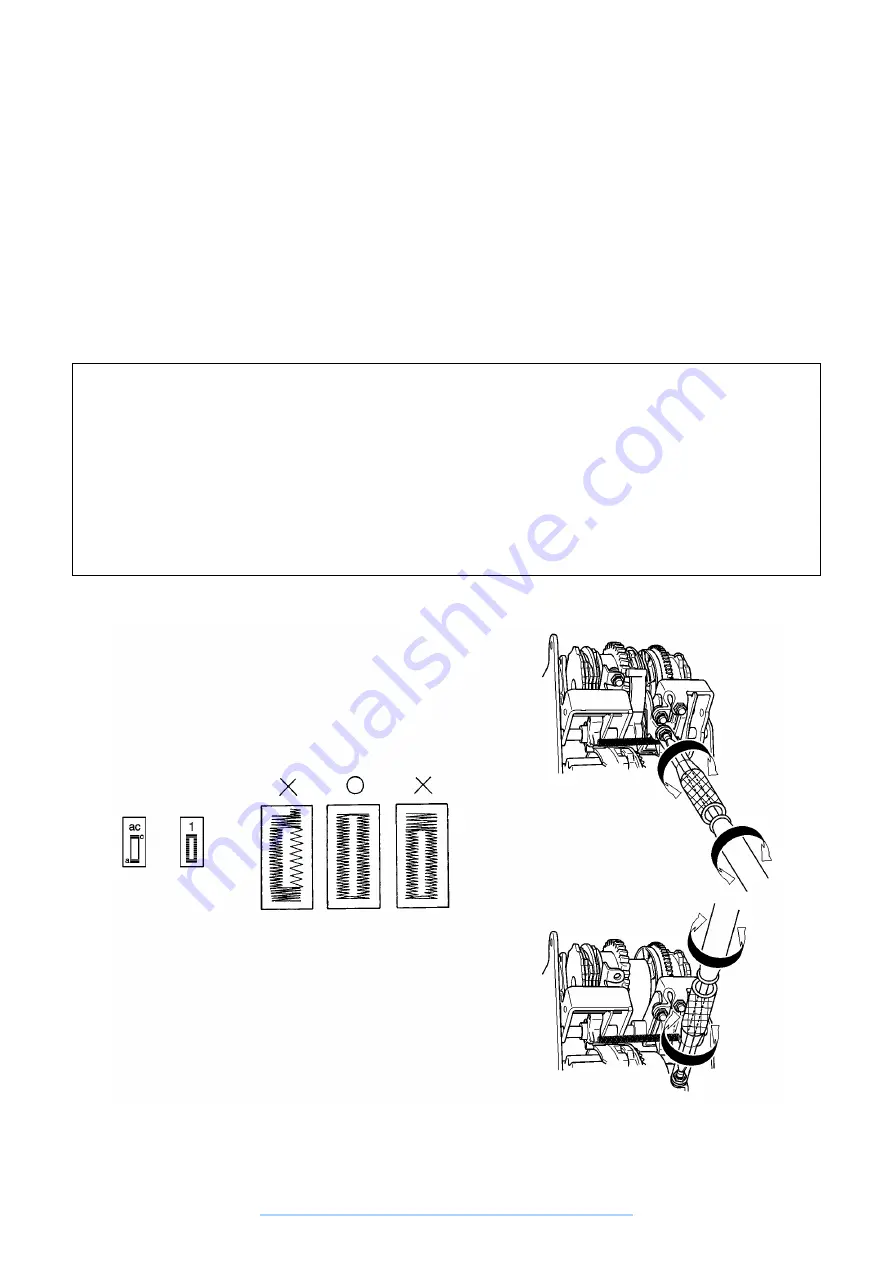

BUTTON HOLE STITCH BAR TACK FEED ADJUSTMENT

STANDARD

The button hole stitch bar tack feed distance should be no greater than 1 mm for 10 pitch.

ADJUSTMENT

1.

Turn the selection dial to BH sewing and execute bar tack sewing.

2.

Loosen the bar tack adjustment screw nut.

3.

Adjust by turning the bar tack adjustment screw.

4.

Tighten the bar tack adjustment screw nut.

Adjustment Points

2.

When adjusting using a box driver as shown in the figure, since the selection dial interferes slightly with

the box driver, remove the selection dial screw and the selection dial beforehand.

3.

To forward the bar tack, turn the adjustment screw to the left. To reverse the bar tack, turn the

adjustment screw to the right.

4.

When fastening the adjustment screw with the nut, in order to maintain the position and prevent deviation,

hold the adjustment screw with the screwdriver while you tighten down the nut.

*

Note that unless the 22. BUTTON HOLE STITCH LEFT REVERSE STITCH AND RIGHT FORWARD

STITCH LENGTH is completed before the button hole stitch bar tack sewing feed adjustment, the button

hole stitch bar tack sewing feed adjustment will need to be repeated.

XL-6060

XL-6050

XL-6040

XL-6060

XL-6050

XL-6040

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...