-54-

26.

FORWARD AND REVERSE STITCH LENGTH

(STRAIGHT LINE STITCH LENGTH)

STANDARD

When the feed dial is to set to 2, there should be no difference between the stitch length for forward and reverse.

ADJUSTMENT

1.

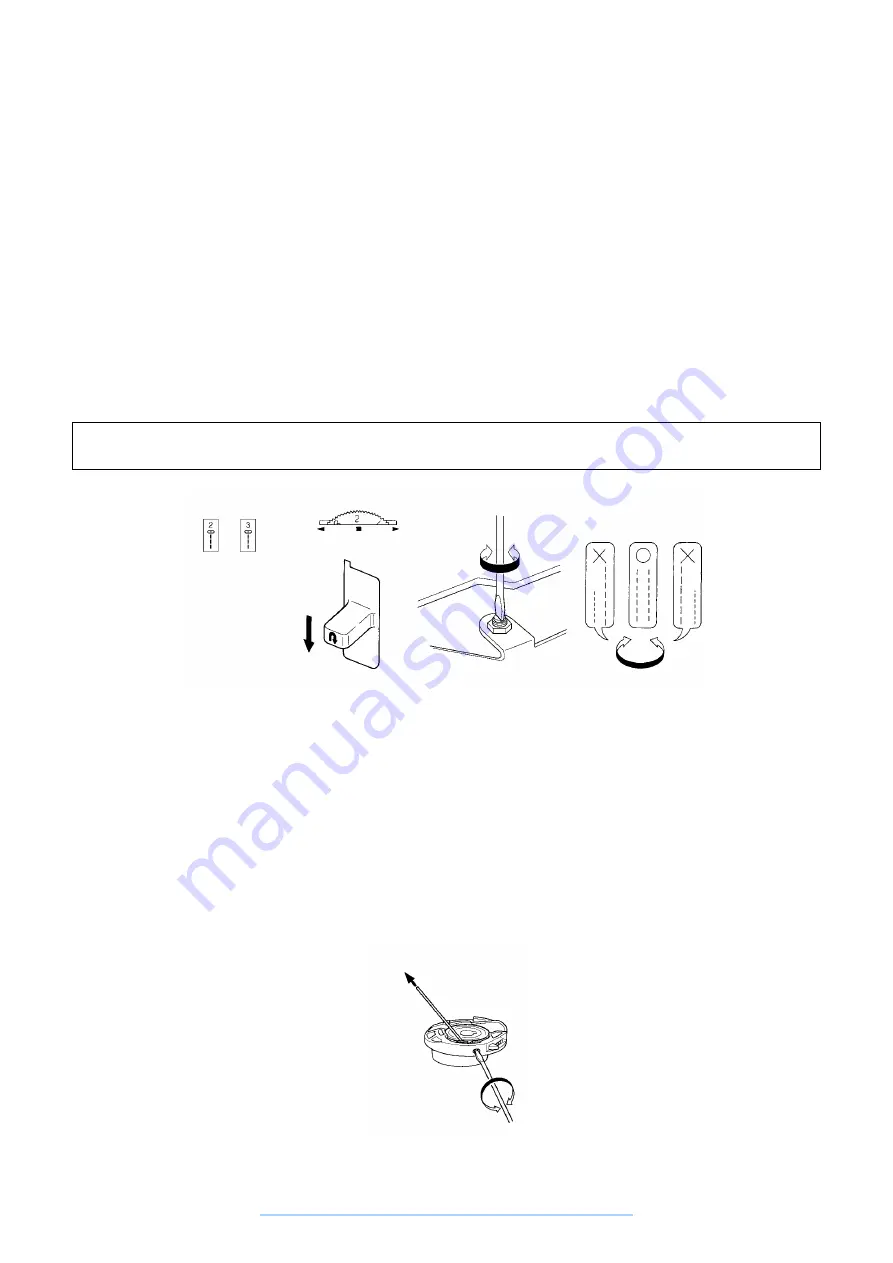

Turn the selection dial to medium straight line sewing.

2.

Set the feed dial to 2.

3.

Lay normal paper under the presser foot, turn the balance wheel, sew in the forward direction, and check

the stitch length then, at another position, while pressing the reverse sewing button, turn the balance wheel,

sew in the reverse direction, and compare the reverse stitch length with the forward stitch length.

4.

Adjust the reverse sewing lever A adjustment screw to match the lengths for forward stitches and reverse

stitches.

Adjustment Point

4.

Turning the adjustment screw to the right increases the length for reverse stitches.

27.

INNER ROTARY HOOK TENSION

STANDARD

The inner rotary hook tension should be 0.1 N - 0.12 N (10-12 gf) when #60 polyester thread is pulled slowly with

the tension gauge.

ADJUSTMENT

1.

Correctly mount a bobbin with polyester thread (#60, green) on the inner rotary hook, then check the tension

by pulling the thread slowly with the tension gauge in the direction shown on the figure.

2.

Turn the spring adjustment screw left and right with the driver to adjust to the inner rotary hook tension.

3.

Check the inner rotary hook tension again with the method in 1.

4.

After the adjustment, paint the adjustment screw with oil-based paint so that the inner rotary hook tension

will not change.

#60 polyester thread

XL-6060

XL-6050

XL-6040

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...