-56-

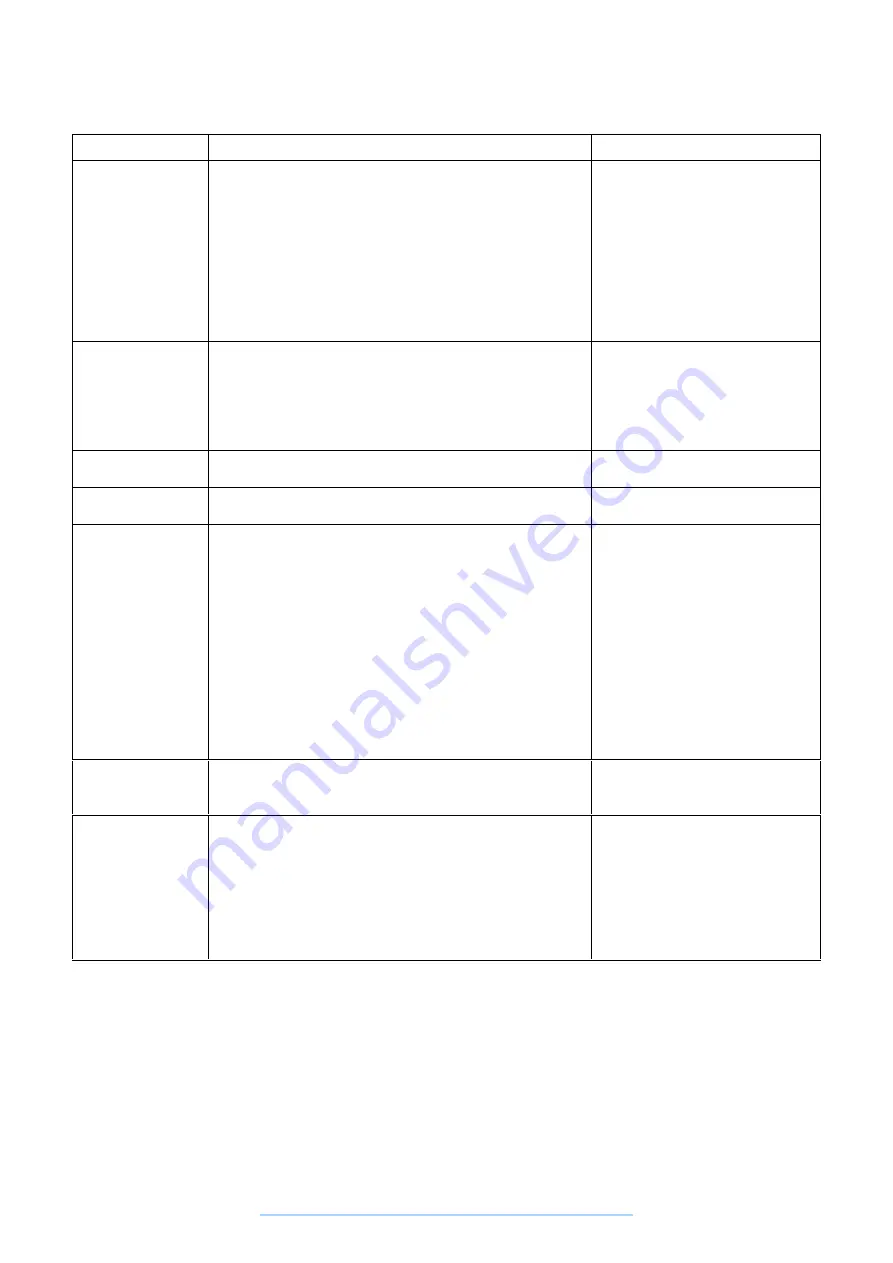

PROBLEM

CAUSE

CORRECTION

1.

Machine skips

stitches.

1. Improper setting of the needle.

2. Bent or blunt needle.

3. Improper threading.

4. Improper combination of needle/ thread/fabric.

5. Stretch fabric is used.

6. Improper timing of the needle and rotary hook.

7. Improper height of the needle bar.

8. Improper clearance between the needle and rotary

hook.

1. Set the needle correctly.

2. Change the needle.

3. Reset threading correctly.

4. Select correct combination of

needle/ thread/fabric.

5. Use stretch fabric needle.

6. Refer to P.35.

7. Refer to P.36.

8. Refer to P.35.

2.

Fabric does not

feed

.

1. Stitch length is set at "0".

2. Improper height of feed dog.

3. Thick fabric.

4. Feed dog is worn out.

5. The feed dog is lowered.

1. Set proper stitch length.

2. Refer to P.40.

3. Change the fabric.

4. Change the feed dog.

5. Raise the feed dog with the

drop lever.

3.

Fabric does not

feed straight.

1. Uneven pressure on right/left side of presser foot.

1. Change the presser foot and

the feed dog.

4.

Upper thread

breaks at start.

1. Improper threading.

1. Thread correctly.

5. Upper thread

breaks during

sewing.

1. Bent or blunt needle.

2. Improper setting of needle.

3. Thread tension is too tight.

4. Thread is tangled.

5. Inferior needle eye.

6. Inferior needle slot of needle plate.

7. Inferior upper thread path.

8. Inferior thread.

9. Needle hits needle plate or rotary hook.

10.There are scratches on inner rotary hook.

1. Change the needle.

2. Set the needle correctly.

3. Adjust tension control dial

correctly.

4. Thread correctly.

5. Change the needle.

6. Change the needle plate.

7. Clean or replace.

8. Check or change the thread.

9. Set the needle bar and rotary

hook correctly.

* Refer to P.35.

10.Change inner rotary hook.

6. Upper thread

breaks during

reverse sewing.

1. Fabric is pulled excessively.

2. Improper use of reverse sewing button.

1. Guide the fabric.

2. Push reverse sewing button

as far as it will allow.

7. Lower thread

breaks.

1. Lower thread tension is too tight.

2. Too much thread is wound on bobbin.

3. Thread is tangled.

4. Bobbin does not turn in inner rotary hook.

5. Inferior thread.

1. Adjust the tension by

loosening the tension spring

screw on inner rotary hook.

2. Change to other bobbin or

adjust bobbin winder.

3. Thread correctly.

4. Change the bobbin.

5. Check or change the thread.

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...