7

could cause the wood to sPlit.

3 The gas system remains in place and does not need to be removed

except for cleaning. If the gas system has been removed, reinstall it

as explained below. Otherwise, proceed to step 5.

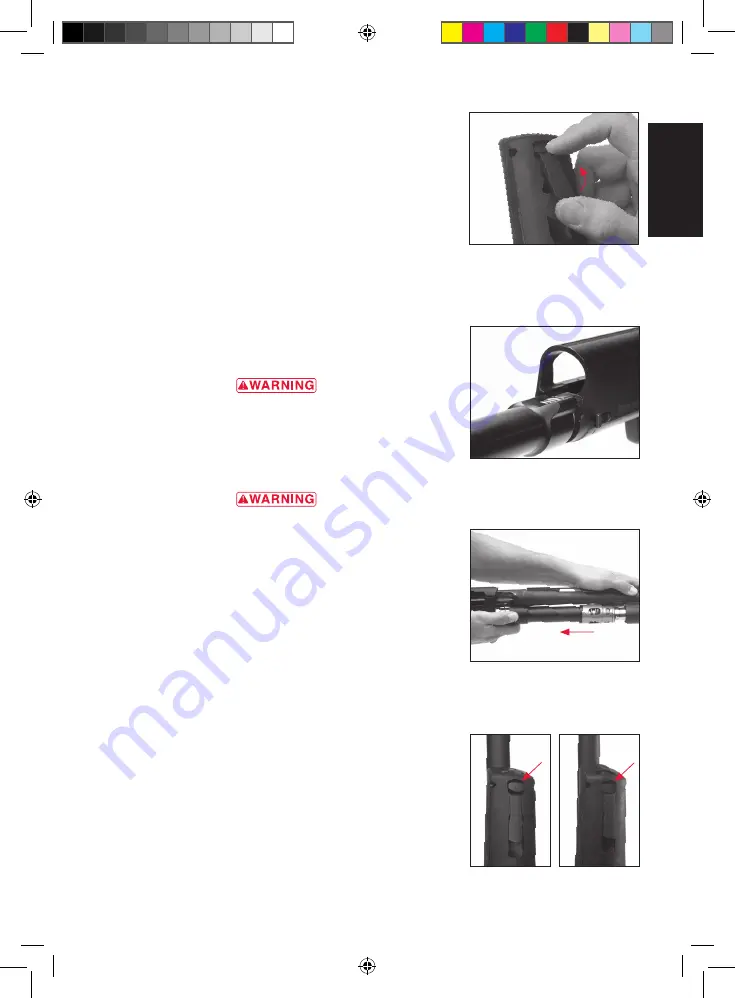

4 Slide the gas system (push rod end first) onto the magazine tube.

Align the push rod with the slot in the left side of the receiver.

(Figure 7). Make sure the gas system spring is properly positioned.

5 Align the barrel extension with the top of the receiver and place

the gas bracket over the magazine tube (Figure 8). The barrel

extension should slip solidly into the receiver. Make sure

the push rod moves freely in its slot in the receiver.

6 Replace the forearm by sliding it onto the magazine tube and over

the gas bracket so it seats securely. Make sure the Speed Lock lever

is fully closed. It may be necessary to push rearward on the

forearm slightly to ensure the forearm is locked in place. When the

forearm is in place and the Speed Lock lever is fully locked, the

release button is flush with the surface of the forearm (Figure 9).

always ensure the ForearM is Fully locKed and the sPeed locK

lever release button is Flush with the surFace oF the ForearM.

Failure to Follow this warning could result in serious injury,

death or daMage to your FirearM.

d i s A s s e m b lY

always KeeP the MuZZle Pointed in a saFe direction. beFore

starting disasseMbly Procedures, oPen the action and visually

insPect the chaMber to be absolutely certain the FirearM is

coMPletely unloaded. Place the ˝saFety” in the on saFe

Position. Failure to Follow this warning could result in

serious injury or death.

1 Lock the bolt rearward by pulling the operating handle fully to

the rear.

NOTICE!

never allow the action to slaM closed by Pressing the

bolt release button without the barrel installed. iF the bolt is

released Forward with the barrel reMoved, the oPerating

handle will striKe the receiver and cause daMage.

2 Remove the forearm as explained previously.

NOTICE!

do not squeeZe hard on the oPen rear end oF a wood

ForearM. too Much Pressure could cause the wood to sPlit.

3 For cleaning, remove the barrel and gas system by sliding

them forward and off the magazine tube. See ˝Cleaning and

Maintenance Suggestions” for cleaning procedures.

For storage, remove the barrel and reinstall the forearm over the

magazine tube. You will then have two compact units: the barrel,

and the action with stock and forearm.

NOTICE!

aFter the barrel has been reMoved, leave the bolt

in the rearward Position. do not Press the bolt release

Figure 7

Align the push rod with the slot in the receiver.

Figure 6

press and hold the release button while lifting

the speed lock lever.

Figure 8

slide the barrel and piston over the magazine

tube and the barrel extension into the receiver.

Figure 9

ensure the forearm is secured correctly, with

the button flush with the forearm, as shown in

the picture on the left.

E

N

BRO5180_Maxus A5_v7.indd 7

02/03/10 13:30

Summary of Contents for MAXUS

Page 6: ...4 E N BRO5180_Maxus A5_v7 indd 4 02 03 10 13 30 ...

Page 26: ...24 E N BRO5180_Maxus A5_v7 indd 24 02 03 10 13 30 ...

Page 27: ...25 Browning maxus Fusils semi automatiques F R BRO5180_Maxus A5_v7 indd 25 02 03 10 13 30 ...

Page 52: ...50 F R BRO5180_Maxus A5_v7 indd 50 02 03 10 13 30 ...

Page 53: ...51 Browning maxus HALBAUTOMATISCHE FLINTE D E BRO5180_Maxus A5_v7 indd 51 02 03 10 13 30 ...

Page 78: ...76 D E BRO5180_Maxus A5_v7 indd 76 02 03 10 13 31 ...

Page 79: ...77 Browning Maxus fucilE semiautomaticO I T BRO5180_Maxus A5_v7 indd 77 02 03 10 13 31 ...

Page 104: ...102 I T BRO5180_Maxus A5_v7 indd 102 02 03 10 13 31 ...

Page 105: ...103 Browning Maxus Escopeta SEMIautomática E S BRO5180_Maxus A5_v7 indd 103 02 03 10 13 31 ...

Page 130: ...128 NOTES E S BRO5180_Maxus A5_v7 indd 128 02 03 10 13 31 ...