7

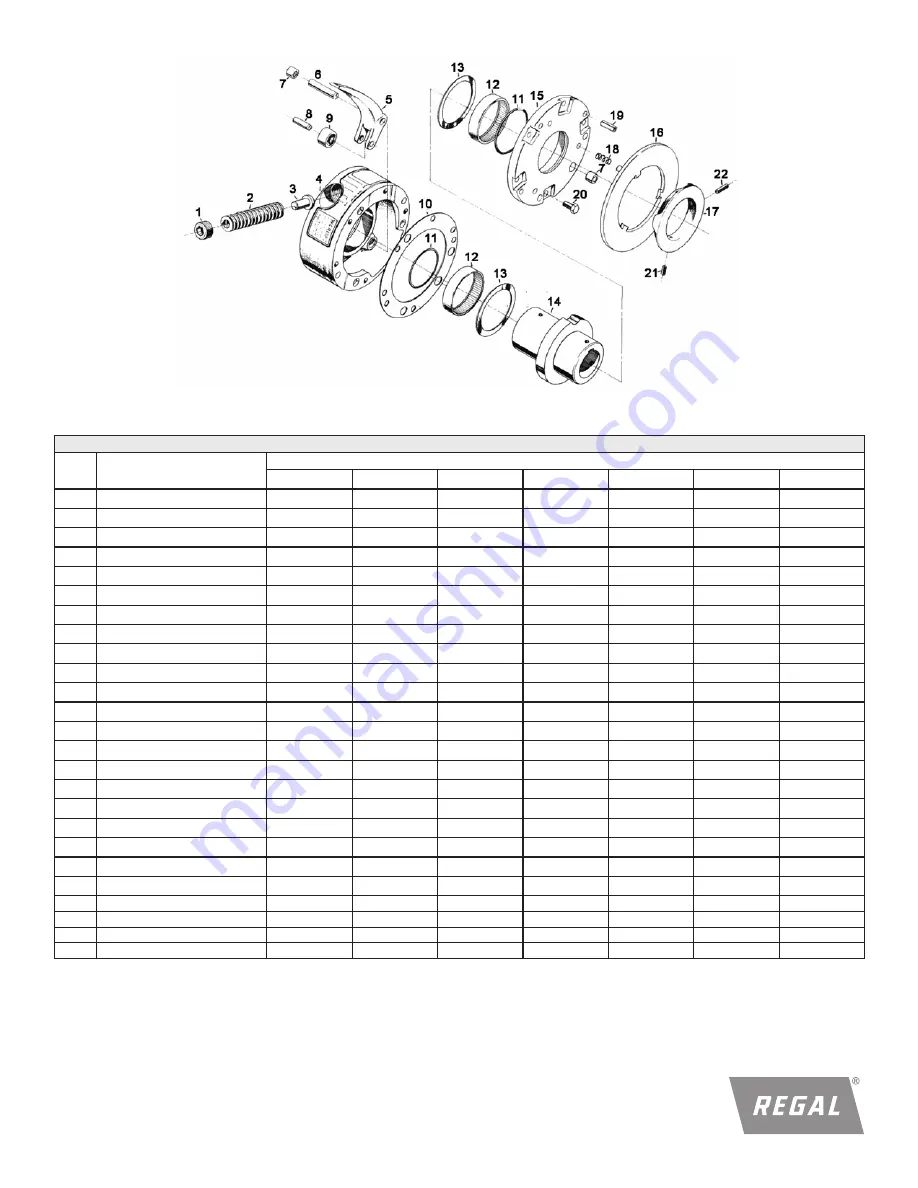

Parts List (Models TG & TGC)

Item Qty

Description

Part Numbers

3

6

20

60

200

400

800

1

1

Adjusting Nut

A-58211

A-58211

A-58238

A-16512

A-16346

B-16680

B-16680

2

1

Spring

A-58255-1

A-58255-2

A-58255-3

A-15731

A-13732

A-16682-1

A-17538-1

2

1

Spring

A-16682-2

A-17538-2

3

1

Button

A-58168

A-58168

A-58171

A-15727

A-13407

A-16685

A-16685

4

1

Body

D-58675

D-58675

C-58695

D-65632

D-65927

D-18715

D-18715

5

1

Lever

B-58202

B-58202

B-58236

B-16510

C-13401

C-16677

C-16677

6

1

Dowel Pin

A-58159

A-58159

A-58165

A-17647

A-17648

A-26007-89

A-26007-89

7

2

Bearing

A-61684

A-61684

A-61687

B-15732-1

A-14407

B-15732-4

B-15732-4

8

1

Dowel Pin

A-58158

A-58158

A-58164

A-17650

A-26007-37

A-26007-65

A-26007-65

9

1

Bearing

A-61685

A-61685

A-61688

A-15730-1

A-14409

A-16683

A-16683

10

1

Gasket

A-58173

A-58173

B-58181

B-73040

C-73044

C-16679

C-16679

11

2

O-Ring

A-58182-1

A-58182-1

A-58182-2

A-15729-2

A-14399

A-15729-3

A-15729-3

12

2

Bearing

A-61683

A-61683

A-61686

B-15732-3

A-14408

B-15732-5

B-15732-5

13

2

Thrust W asher

A-58172

A-58172

A-58174

A-16511

B-13406

B-16681

B-16681

14

1

Drive Hub

B-58609

B-58609

B-58668

B16506

C-76760

D-18719

D-18719

15

1

Cover

B-58250

B-58250

B-58260

C-65649

D-65879

D-16675

D-16675

16

1

Detector Plate

B-58794

B-58794

B-58383

B-17056

C-16927

C-17076

C-17076

16A 1

Prox Detector Plate Assy

B-71122

C-71123

C-71126

C-71126

17

1

Cam-Detect Plate

B-58795

B-58795

B-58385

B-17055

B-76762

C-17077

C-17077

18

3

Spring

A-53740-4

A-53740-4

A-53052-4

A-17059

A-16989

A-17788

A-17788

19

2

Roll Pin

A-26023-35

A-26023-35

A-26023-37

A-73403-1

A-73403-2

A-26023-71

A-26023-71

20

5

Hex HD Cap Screw

A-26015-17

A-26015-17

A-26015-23

A-18874-2

A-26002-15

20

7

Hex HD Cap Screw

A-18876-2

A-18876-2

21

1

Soc HD Set Screw

A-26005-16

A-26005-16

A-26005-16

A-26005-39

A-26005-45

A-26005-77

A-26005-77

22

2

Soc HD Set Screw

A-26005-17

A-26005-17

A-26005-17

A-26005-40

A-26005-46

A-26005-79

A-26005-79