INTRODUCTION

TYPICAL PAGE

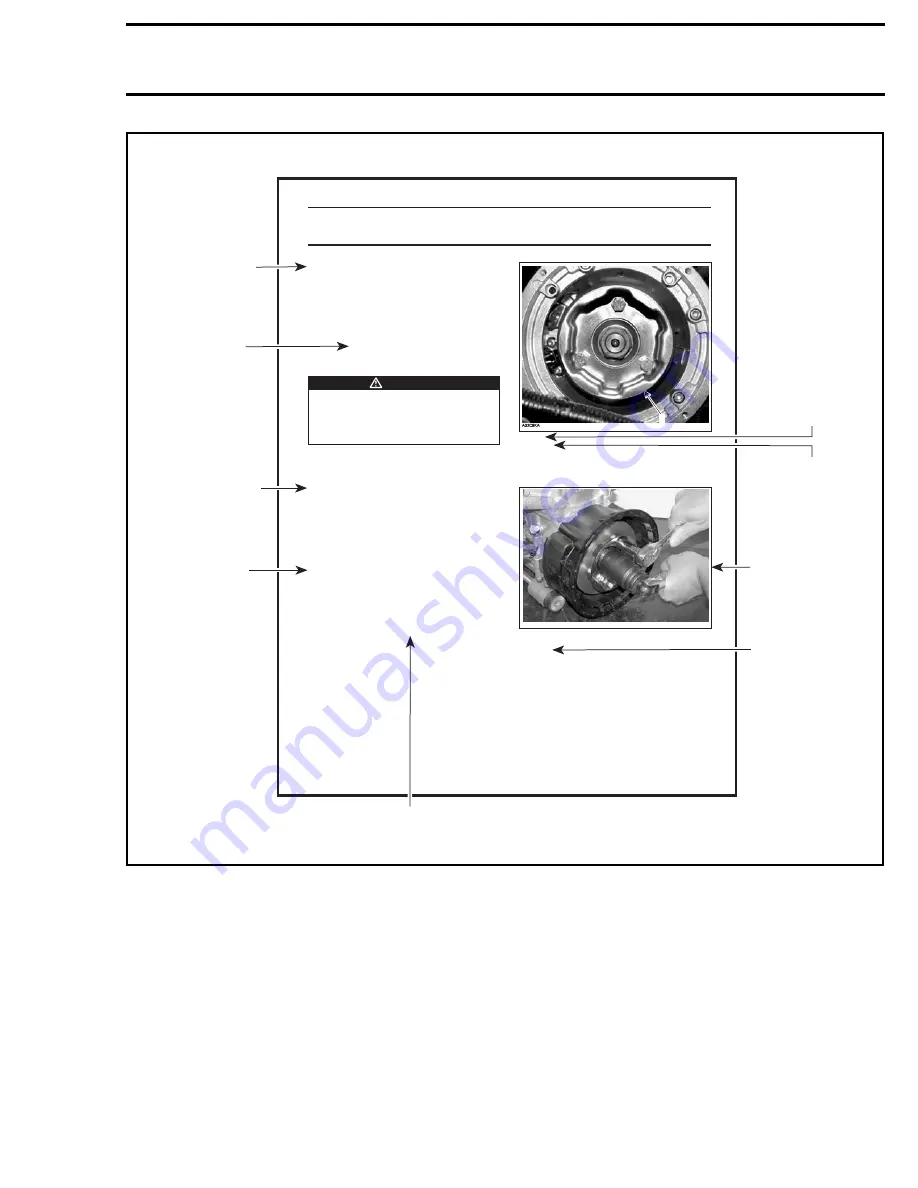

Subsection 09 (MAGNETO SYSTEM)

GENERAL

NOTE:

The following procedures can be done

without removing the engine.

During assembly/installation, use the torque val-

ues and service products as in the exploded

views.

Clean threads before applying a threadlocker. Re-

fer to the

SELF-LOCKING FASTENERS

and

LOC-

TITE APPLICATION

sections at the beginning of

this manual for complete procedure.

WARNING

Torque wrench tightening specifications

must be strictly adhered to.

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

be replaced with new ones.

PROCEDURES

MAGNETO FLYWHEEL

Magneto Flywheel Cleaning

Clean all metal components in a non-ferrous metal

cleaner.

CAUTION:

Clean magneto flywheel using only

a clean cloth.

Magneto Flywheel Removal

Remove muffler, refer to the

EXHAUSTSYSTEM

section.

Remove acoustic panel.

Remove rewind starter.

Remove starting pulley

no. 2

.

TYPICAL

NOTE:

To remove starting pulley bolts, hold mag-

neto flywheel with a socket as shown.

TYPICAL

Models

Remove the connecting flange retaining the

rewind starter to the engine housing.

Section 03 ENGINE

1. Starting pulley

1

Subsection 09 (MAGNETO SYSTEM)

GENERAL

NOTE:

The following procedures can be done

without removing the engine.

During assembly/installation, use the torque val-

ues and service products as in the exploded

views.

Clean threads before applying a threadlocker. Re-

fer to the

SELF-LOCKING FASTENERS

and

LOC-

TITE APPLICATION

sections at the beginning of

this manual for complete procedure.

WARNING

Torque wrench tightening specifications

must be strictly adhered to.

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

be replaced with new ones.

PROCEDURES

MAGNETO FLYWHEEL

Magneto Flywheel Cleaning

Clean all metal components in a non-ferrous metal

cleaner.

CAUTION:

Clean magneto flywheel using only

a clean cloth.

Magneto Flywheel Removal

Remove muffler, refer to the

EXHAUSTSYSTEM

section.

Remove acoustic panel.

Remove rewind starter.

Remove starting pulley

no. 2

.

TYPICAL

NOTE:

To remove starting pulley bolts, hold mag-

neto flywheel with a socket as shown.

TYPICAL

Models

Remove the connecting flange retaining the

rewind starter to the engine housing.

Section 03 ENGINE

1. Starting pulley

1

Indicates component

procedures apply to.

Reference to a

specific section

or subsection.

Call-outs pertaining

to above illustration.

Italic bold face type-

setting indicates a

procedure applicable

to a specific

model(s).

TYPICAL

indicates a general

view which may

not represent exact

details.

Illustration always

follows text to which

it applies.

Indicates specific

procedure to be

carried out.

Bold face number following part

name refers to exploded view

at beginning of subsection.

mmr2007-016-002

Tittle in bold

indicates category

of information to be

carried out.

mmr2008-001

57

typical_txt_2008_en

tmr2013-002

XV

www.MilitaryAtv.com