179

Oiling System

Oiling System Tests

8

Use the

Oil Injector

test of

Evinrude Diagnostic

software

Static Test

screen to activate the oil

pump.

Observe voltage at pin 2.

•

Voltage at pin 2 should drop as the oil pump

cycles.

Check the control signal while the

Oil Injector

test

is running. Set the digital multimeter to the Hertz

(Hz) scale.

•

Meter should read approximately 10 Hz.

Results:

•

If voltage and control signal readings at pin 2

are within range, the

EMM

and wiring are not at

fault.

•

If voltage at pin 2 is not within range, check volt-

age at pin 1 (white/red wire) of oil pump electri-

cal connector.

Connect positive meter lead to pin 1 (white/red

wire) of oil injection pump electrical connector.

Observe voltage at pin 1.

•

Voltage at pin 1 should be approximately 30 V.

Start the engine. Observe voltage at pin 1.

•

The voltage at pin 1 should be approximately

55 V.

•

If voltage is not within range, refer to

tion Pump Circuit Resistance Test

•

No voltage reading, refer to

Oil Injection Pump Circuit

Resistance Test

IMPORTANT:

The complete oil injection pump

electrical circuit includes

EMM

alternator output,

the engine wire harness, the injection pump wind-

ing and connectors, and the oil injector control cir-

cuit of the

EMM

. Check continuity of all wiring and

connections.

Disconnect the battery cables at the battery.

Disconnect J1-B connector from

EMM

. Use a digi-

tal multimeter with appropriate adapter leads to

measure the resistance between pin 23 (blue) of

the

EMM

J1-B connector and pin 1 (white/red) of

the oil injection pump connector. Calibrate the

meter to the LOW OHMS scale.

•

An infinite reading (

∞

) indicates an open circuit.

Isolate the faulty component. Check continuity

of wiring, connections, or injection pump wind-

ing. Repair faulty wiring or replace faulty pump.

•

For a higher than expected reading, test resis-

tance of the injection pump. If injection pump

resistance reading is within range, injection

pump winding is good. Isolate faulty compo-

nent. Repair faulty wiring or replace faulty com-

ponent and retest.

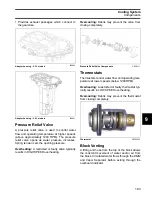

Static Tests Screen

1.

Oil injector test button

008579

1

Oil Injection Pump Circuit Resistance

2 to 3

Ω

1.

EMM

J1-B connector (pin 23)

2.

Oil injection pump connector (pin 1)

004343

2

1

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

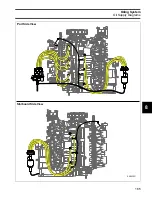

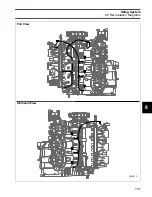

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

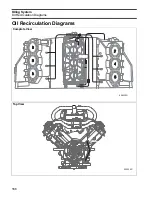

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...