33

Routine Service

Adjustments

2

Incorrect outboard alignment could cause one or

more of the following:

•

Propeller ventilation

•

Reduction of top speed

•

Improper boat tracking

•

Engine overheat and powerhead damage

Follow the instructions provided by the tie-bar

manufacturer for tie bar installation and adjust-

ment.

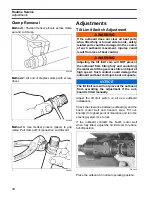

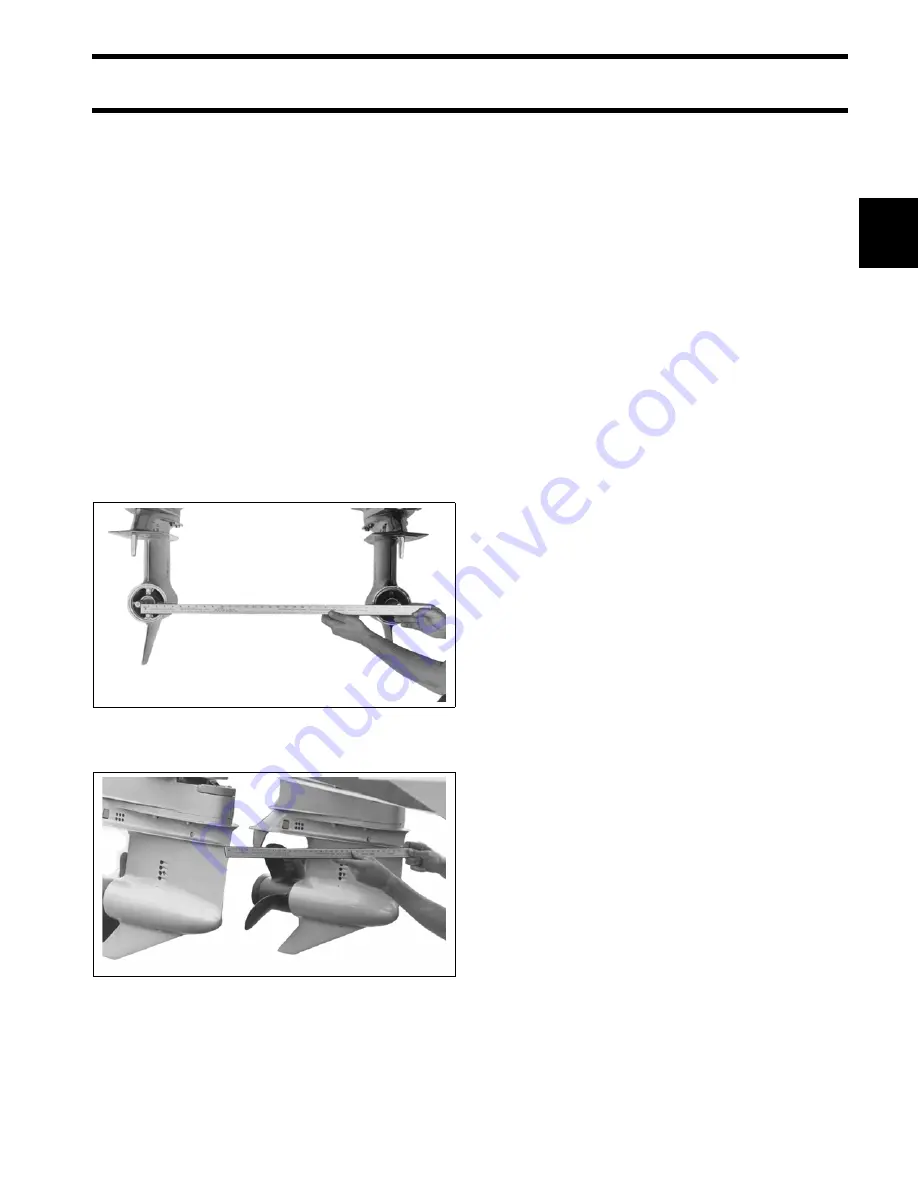

Measure Alignment

The “toe-in” (gearcase leading edges closer

together than propeller shaft centers) or “toe-out”

(gearcase leading edges farther apart than propel-

ler shaft centers) is determined as follows:

•

Position outboards straight with the anti-ventila-

tion plates parallel with the bottom of the boat.

•

Measure between propeller shaft centers.

•

Measure between leading edges of gearcase.

Alignment Adjustment

Various boat/motor combinations respond differ-

ently to dual-outboard alignments. Each applica-

tion must be thoroughly tested until the ideal

combination of performance, steering, and cooling

is found.

A common practice is to set-up the outboards par-

allel, or with a small amount of “toe-out,” and

adjust inward until best results are achieved.

•

A typical set-up with 2-stroke outboards

mounted directly on the transom often runs best

with a slight amount of “toe-in.”

•

Outboards mounted behind the transom on

motor brackets usually require “parallel” align-

ment or “toe-out.”

Adjust the outboard alignments by adjusting tie

bar. Follow the tie bar manufacturer’s adjustment

procedures.

Check steering operation. Make sure that the

steering system operates properly at various trim

angles.

Confirm Alignment

To confirm proper alignment, perform the following

steps:

•

Water test the boat.

•

Monitor the water pressure for both outboards.

•

Run the boat at various trim angles.

•

Perform steering maneuvers and vary the throt-

tle settings.

•

Monitor boat and outboard performance.

A sudden loss of water pressure or excessive pro-

peller ventilation on one or both outboards may

indicate a misalignment of the gearcases. Reset

the outboard alignment and retest.

6365

6340

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...