109

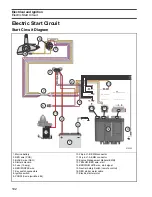

Electrical and Ignition

SystemCheck Circuit Tests

6

SystemCheck

Circuit

Tests

Make sure the

SystemCheck

engine monitor can

alert the operator during a “NO OIL,” “WATER

TEMP” or “HOT,” “CHECK ENGINE,” or “LOW

OIL” condition. Check the condition of the warning

system and associated wiring and connections.

Test the engine monitor regularly and anytime you

suspect an alert situation has been missed.

The instrument harness must be connected to the

outboard before performing the following tests.

Refer to the

Engine Wiring

diagram and the

MWS Instrument Wiring

diagram in the back of

this manual.

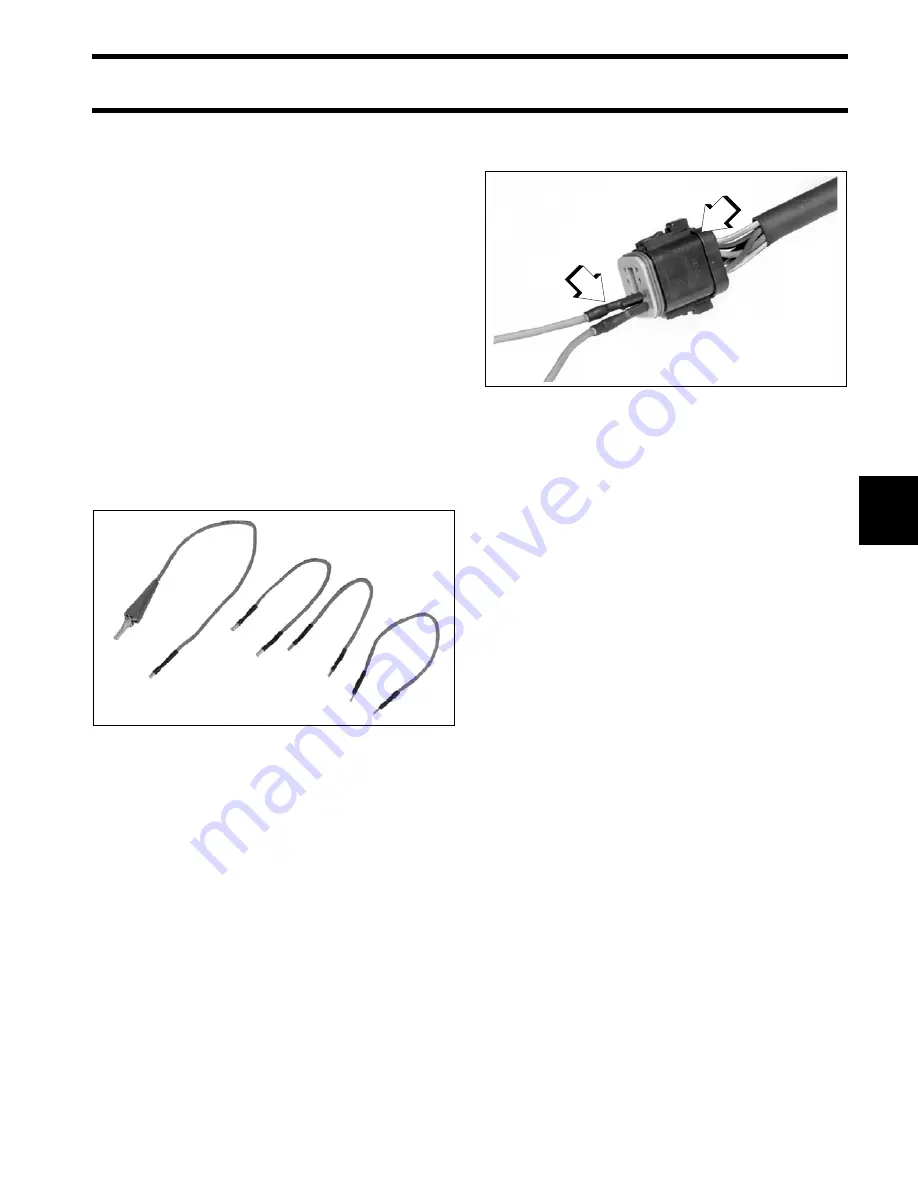

IMPORTANT:

Use jumper wires made with the

appropriate terminals to test the warning circuits.

Gauge Self-Test Check

Turn the key switch to ON with the outboard NOT

running. The gauge warning lights for NO OIL,

WATER TEMP, CHECK ENGINE, and LOW OIL

must all light at once, then turn off in sequence,

and the warning horn must sound for one-half

second.

If the gauge lights do not turn on, turn the key

switch OFF. Disconnect the gauge 8-pin connec-

tor from the back of the gauge and turn the key

switch ON. Test for battery voltage between

instrument harness terminal 1 (purple wire) and

terminal 2 (black wire).

•

If battery voltage is present, replace the gauge.

•

If there is no battery voltage, check that 12 V is

present at terminal “B” of the key switch. Check

condition of the instrument harness, key switch,

and connections.

If the lights worked, but the warning horn did not

sound for one-half second, turn the key switch

OFF. Disconnect the warning horn 2-pin connec-

tor. Substitute a known good warning horn. Turn

the key switch ON.

•

If the substitute horn beeps, the original horn is

defective and must be replaced.

•

If the substitute horn does not beep, check for

battery voltage between instrument harness 2-

pin connector, terminal 2 (purple wire) and

ground with the key switch ON. Also, check the

tan/blue wire for continuity between pin 8 of the

8-pin connector and pin 1 of the 2-pin connec-

tor.

•

If battery voltage is present at the purple wire

and the tan/blue wire has continuity between

42811

1.

Test adapter(s)

2.

Connector,

SystemCheck

gauge

42761

1

2

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...