143

Fuel System

Fuel System Tests

7

Fuel System Tests

Fuel System Pressure Test

Relieve fuel system pressure. See

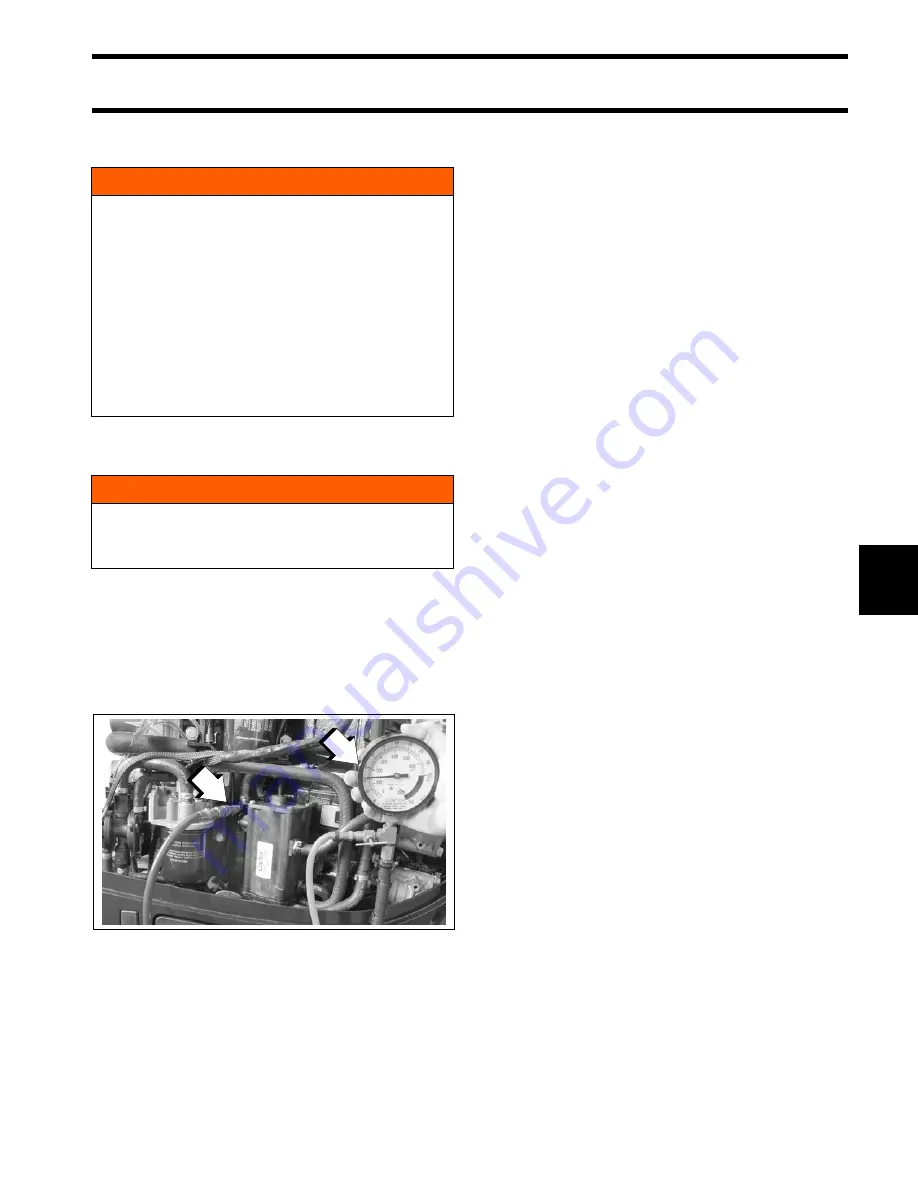

After relieving fuel system pressure, install a 0 to

60 psi (0 to 415 kPa) Fuel Pressure Gauge,

P/N 5007100 or equivalent, to the upper fuel pres-

sure test fitting.

START outboard and check pressure. System

pressure should be 20 to 35 psi (138 to 241 kPa).

Shut OFF outboard. Monitor pressure gauge.

Pressure should not drop below 15 psi (103 kPa).

IMPORTANT:

If outboard does not run, prime

fuel system and crank outboard; check circulation

pump operation; check fuel system pressure.

Results:

Normal pressure

•

Observe pressure reading after outboard is shut

OFF.

•

Refer to

Pressure drops after outboard is shut OFF:

•

Check for leaking fuel injector.

•

Check for leaking pressure regulator.

•

Check for external fuel system leak.

High pressure:

•

Check for restricted filter or fuel return fitting of

vapor separator, damaged pressure regulator in

vapor separator, or restricted fuel return mani-

fold.

Low pressure

•

Check fuel supply to fuel lift pump. Refer to

on p. 146. Higher vacuum

readings indicate restrictions in the fuel supply.

Repair or replace as needed.

•

Restricted fuel filter/water separator assembly.

•

Lift pump not supplying adequate fuel to vapor

separator. Refer to

•

If the above tests are good and vapor separator

remains full of fuel, check for damaged circula-

tion pump. Replace vapor separator assembly.

No pressure

•

Check electrical circuit and ground connections

for circulation pump.

•

If voltage is present and pump does not run,

repair connection or replace vapor separator

assembly.

Relieve fuel system pressure before removing fuel

pressure gauge. Refer to

Pressure Regulator Test

remove vapor separator.

Make sure filter is not clogged. Clean or replace

as needed.

WARNING

Use caution when working on any pressur-

ized fuel system. Wear safety glasses and

work in a well ventilated area. Extinguish all

smoking materials and make certain no open

flames or ignition sources exist. Before start-

ing any fuel system service, carefully relieve

fuel system pressure. Failure to properly

relieve fuel system pressure can result in

spraying fuel and/or excessive fuel spillage

during servicing. Fuel is flammable and can

be explosive under certain conditions.

WARNING

Protect against hazardous fuel spray. Before

starting any fuel system service, carefully

relieve fuel system pressure.

1.

Fuel pressure gauge

2.

Test fitting

004324

1

2

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...