44

INSTALLATION AND PREDELIVERY

PROPELLER SELECTION

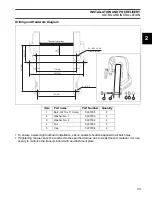

Propeller Hardware Installation

Apply

Triple-Guard

grease to the entire propeller

shaft before installing the propeller.

Install thrust bushing onto propeller shaft with

shoulder of thrust bushing facing aft. Taper of

bushing must match taper of propshaft.

Install propeller on propeller shaft by aligning

splines and pushing until seated on the thrust

bushing.

IMPORTANT:

Depending on propeller style, dif-

ferent thrust bushings, spacers, and cotter pin

keepers are used. See the

Evinrude/Johnson

Genuine Parts

book for a complete listing and

descriptions.

Install the spacer, engaging the propeller shaft

splines.

Wedge a block of wood between propeller blade

and the anti-ventilation plate.

Install the propeller nut and torque to:

•

217 in. lbs. (24.5 N·m)

If cotter pin holes in the propeller nut and propeller

shaft are not aligned, tighten the nut until they are

in line. Do not loosen.

Insert a new cotter pin through the propeller nut

and shaft. Bend its ends over the nut to secure the

assembly.

IMPORTANT:

After fastening propeller nut,

make sure outboard is in NEUTRAL and carefully

spin propeller. Propeller must turn freely and

should not spin off center. If propeller appears to

wobble, check for possible bent propeller shaft.

WARNING

When servicing the propeller, always shift

the outboard to NEUTRAL, turn the key

switch OFF, and twist and remove all spark

plug leads so the engine cannot be started

accidentally.

1.

Thrust bushing

2.

Propeller

3.

Spacer

4.

Washer

5.

Propeller Nut

6.

Cotter pin

004361

DRC3984