BRP-Rotax

REPAIR MANUAL

Piston classification “h”

Piston labeling

Tolerance field

(mm)

Minimum dimen-

sion (mm)

Maximum dimen-

sion (mm)

“h” 53.94

+0.015 / -0.015 mm

53.925

53.955

“h” 53.95

+0.015 / -0.015 mm

53.935

53.965

“h” 53.96

+0.015 / -0.015 mm

53.945

53.975

“h” 53.97

+0.015 / -0.015 mm

53.955

53.985

“h” 53.98

+0.015 / -0.015 mm

53.965

53.995

______________________________________________________

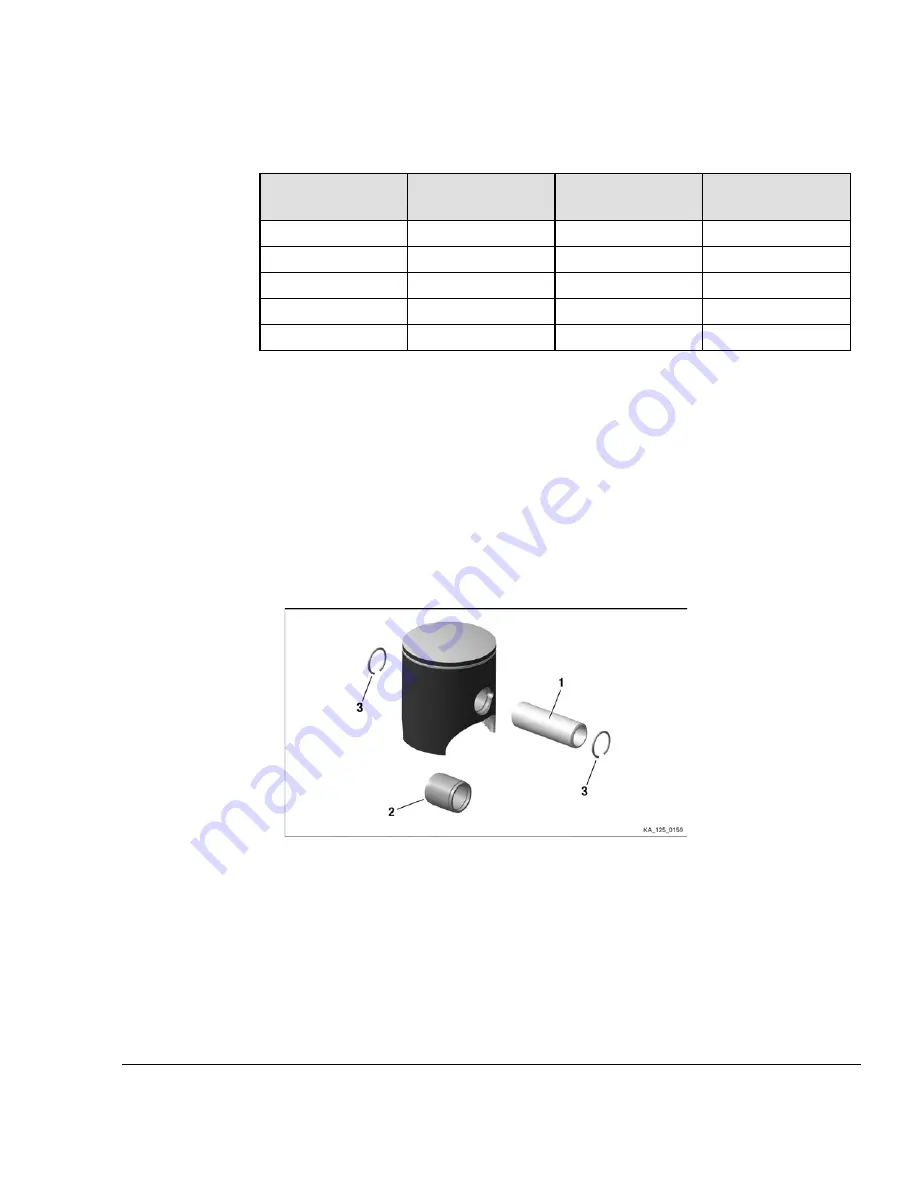

INSPECTION OF THE PISTON PIN, CIRCLIP

Instructions

1.

Inspect the piston pin (1) for wear and discoloration.

2.

Check the needle cage (2) for cracks and abrasion.

3.

The circlips (3) are replaced at every repair. Notice the position of the circlip.

NOTE

Direction of circlips is up or downside direction.

Figure 4.13: Piston pin, circlip

1

Piston pin

2

Needle cage

3

Circlip

______________________________________________________

Effectivity: 125 MAX evo, Junior MAX

evo, Mini MAX evo, Micro MAX evo

Page 15

November 01 2021

Summary of Contents for Rotax 125 JUNIOR MAX evo

Page 174: ......