35

MAINTENANCE PROCEDURES

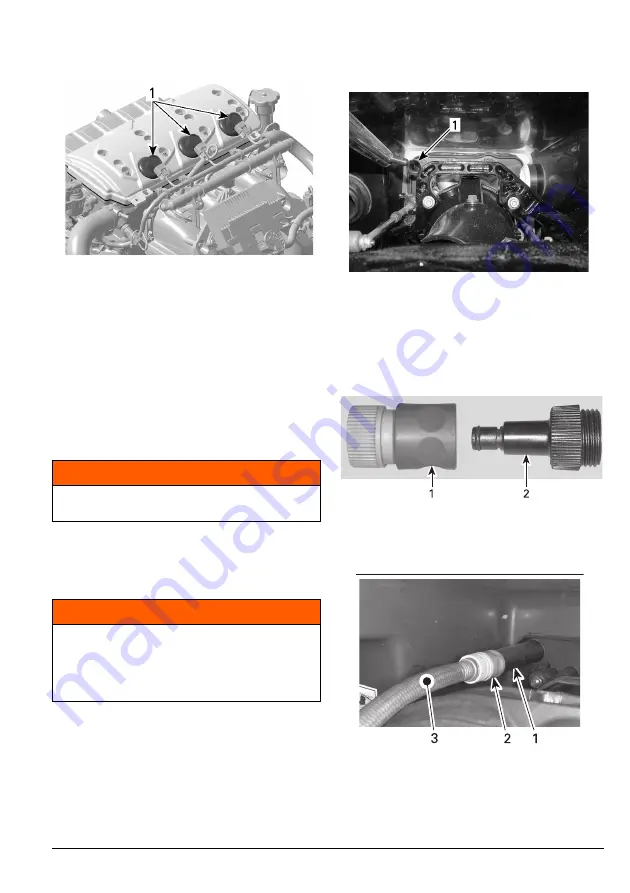

3) Ensure the seal seats properly with top sur-

face of engine valve cover.

EXHAUST SYSTEM

Exhaust System Flushing

Flushing the exhaust system and intercooler

of each engines with fresh water is essential

to neutralize corroding effects of salt or other

chemical products present in water. It will help

to remove sand, salt, shells or other particles

in water jackets and/or hoses.

Proceed as follows:

1) Clean jet pump by spraying water in its inlet

and outlet and then apply a coating of XPS

Lube, P/N 460786, or equivalent.

2) Connect a garden hose to the connector lo-

cated at the rear of boat on jet pump sup-

port. Do not open water tap at this time.

IMPORTANT:

Use optional Flushing Adapter,

P/N 460711, with a quick connect adapter to

ease garden hose installation. A hose pincher

is NOT required to flush engine.

TYPICAL

1. Seal properly seated

smr2009-032-004

WARNING

Perform this operation in a well venti-

lated area.

WARNING

When operating the engine while the

boat is out of the water, the heat

exchanger in the ride plate may become

very hot. Avoid any contact with ride

plate as burns may occur.

TYPICAL

1. Flushing connector

lmo2007-003-030_a4

TYPICAL

1. Quick connect adapter

2. Flushing connector adapter

B00068

TYPICAL

1. Flushing connector

2. Quick connect adapter and flushing

3. Garden hose

B00069

Summary of Contents for Rotax 4-TEC 150

Page 5: ...Safety And Warranty Information ...

Page 28: ...24 Safety And Warranty Information NOTES ...

Page 29: ...25 Inspections and Maintenance ...

Page 45: ...41 Technical Information and Specifications ...

Page 50: ...46 Technical Information and Specifications NOTES ...

Page 51: ...47 Troubleshooting Guidelines ...

Page 59: ...55 Break In and Special Procedures ...

Page 63: ......