02-2010

17

Place

Symbol

Description

How can I avoid the danger?

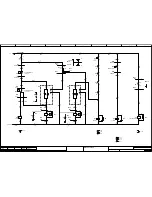

Elektric

Danger through electric current

As with all electrical work, there is the

danger of electric shocks, short-

circuits etc.

All maintenance work, especially electrical work,

may only be carried out by suitably trained and

qualified persons

Isolate the refrigeration aggregate from the

mains supply before staring maintenance work

The main switch is to be fitted with a suitable

padlock

Complete aggregate

Danger through materials and

other substances (or the other

components thereof)

All information about dangers has to be made

easily accessible to the operators and made

available nearby

Only suitable trained personnel

Complete aggregate

Danger through internal/external

contact with liquids

Observance of the danger datasheets

Customer-sided filling of cooling medium is to be

documented

Cooling tank,

cooling system

Danger through burns

e.g. during maintenance, cleaning or

fault corrections

¾

Wait till parts cool down to under 40°C

¾

Use protective gloves:

Maintenance procedures are to be adhered to.

No technical changes to the refrigeration unit on the side of the customer are to be carried

out without agreement with the manufacturer.

Technical documentation for the machine is kept with the manufacturer for at least 10

years.

All changes to the documented technology are to be agreed upon with the manufacturer.

A change is only a change when it is not concerned with a homologous replacement within

the documented technology.

10.1 Maintenance for the operator

At regular intervals, the status of the cooling medium is to be checked and the medium is to

be topped up if so required.

It is recommended to check the tightness of all screw-connections in the circulations of

medium and cold water, resp. the oil circulation regularly 2 times a year.

The air intake of the pump is to be checked at regular weekly intervals for contamination i.e.

for free intake of the cooling air and cleaned if so required.

At certain prescribed time intervals, regular legally-binding leakage tests on the cooling

agent circuit have to be carried out by certified personnel. These persons have to present

their qualifications to the satisafction of the owner/operator. Test intervals are directly

dependant on the cooling agent amount and vary between yearly ( above 3kg i.e. 6kg in the

case of Hermetic systems), half-yearly (above 30kg) and quarter-yearly (above 300kg).

Tests are to be documented in one of the special manuals prepared for the unit. A suitable

operating manual is available from the manufacturer.

Summary of Contents for Typ BR 058-31

Page 23: ......