ELCB

H172203_1_001

57 / 234

8.4.1

Protection

The power amplifier providing the lock current for the H0 coil is protected against short

circuits (limiting the output current) and over temperature.

8.4.2

Lock Software Architecture

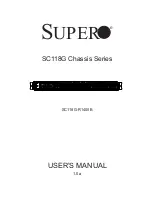

Figure 8.3: Abstract Control Domain and Real Time Domain

One part of the Lock software runs in „real time“ mode: An interrupt service routine is called

every 75 microseconds. This routine reads the Lock receiver data and evaluates the

corresponding Ctrl-DAC and Field-DAC values, which are applied by the Control FPGA to the

hardware. The typical delay time from arrival of the receiver data to the completion of the

DAC write cycle is less than 25 micro seconds.

On the other hand, there is a more abstract part, modelling the Lock behavior and controlling

higher level functions, e. g. locking in, selecting the appropriate set of Regulator Coefficients,

compensating the drift and so on. This part of the software is connected with the CORBA

interface - it handles requests from the TopSpin application and notifies about state changes

(e. g. Lock Hold). It is non-real time and may react with a delay of several milliseconds.

The Lock Hold signal affects directly the regulator, which guarantees extremely short reaction

times. An external Lock Hold Observer examines every 20 milliseconds the Lock Hold state.

If the regulator runs in Lock Hold mode or if a short Lock Hold pulse has been active in the

mean time (Lock Hold Escaped) then the Lock Hold Observer updates the Lock Control State

Machine and notifies the registered clients - even the shortest Lock Hold pulses are indicated

on the keyboard (if connected) and in the TopSpin application.

Summary of Contents for NMR AV4 BSMS System

Page 1: ...BSMS System for AVANCE NEO User Manual Version 001 Innovation with Integrity NMR...

Page 10: ...Contents x H172203_1_001...

Page 22: ...Safety 22 234 H172203_1_001...

Page 26: ...Transport Packaging and Storage 26 234 H172203_1_001...

Page 42: ...Chassis Mainframe 42 234 H172203_1_001...

Page 46: ...Fan Tray 46 234 H172203_1_001...

Page 55: ...ELCB H172203_1_001 55 234 Figure 8 1 ELCB Front Panel with LED s and Connectors...

Page 69: ...ELCB H172203_1_001 69 234 Figure 8 13 Lock RF Boards Diagnostics...

Page 70: ...ELCB 70 234 H172203_1_001...

Page 120: ...L TRX L 19F 120 234 H172203_1_001...

Page 148: ...BSVT Concept 148 234 H172203_1_001...

Page 166: ...SPB 166 234 H172203_1_001...

Page 172: ...VPSB DC and VPSB DC E 172 234 H172203_1_001 Figure 15 3 Block Diagram of the VPSB DC E...

Page 180: ...VPSB DC and VPSB DC E 180 234 H172203_1_001...

Page 187: ...VTA H172203_1_001 187 234 Figure 16 1 VTA Cable Connectors...

Page 193: ...VTA H172203_1_001 193 234 16 7 Ordering Information See Basic BSVT Configuration 124...

Page 194: ...VTA 194 234 H172203_1_001...

Page 200: ...Nitrogen Level Sensor 200 234 H172203_1_001...

Page 204: ...Radiation Shield Temperature Monitoring MAG RS 204 234 H172203_1_001...

Page 208: ...Installation and Initial Commissioning 208 234 H172203_1_001...

Page 210: ...Operation 210 234 H172203_1_001...

Page 216: ...Replacement of Parts 216 234 H172203_1_001...

Page 222: ...Contact 222 234 H172203_1_001...

Page 226: ...List of Figures 226 234 H172203_1_001...

Page 229: ...Glossary H172203_1_001 229 234 Glossary...

Page 230: ...Glossary 230 234 H172203_1_001...

Page 232: ...Index 232 234 H172203_1_001...

Page 233: ...H172203_1_001 233 234...

Page 234: ...Bruker Corporation info bruker com www bruker com Order No H172203...