6-7

Maintenance

Section 6

The damage can range from cosmetic to structural,

although structural damage is a rare occurrence.

Studies point to long-term immersion of a boat in warm

water as a primary cause of hull blisters. Stress

cracks on the hull below the waterline can also contrib-

ute to the formation of blisters.

There are a number of important things that you

can do to avert hull blistering. They include:

Storage

Store your boat out of the water when not in use.

Store your boat on a trailer, in a boatlift, or on a cradle.

Be sure to use a bunk style design that supports the

boat well.

Inspection

Inspect the entire surface of the boat bottom on a fre-

quent basis. Address any structural or cosmetic

issues immediately. Even a minor scratch or scrape

might allow water to enter the hull laminate.

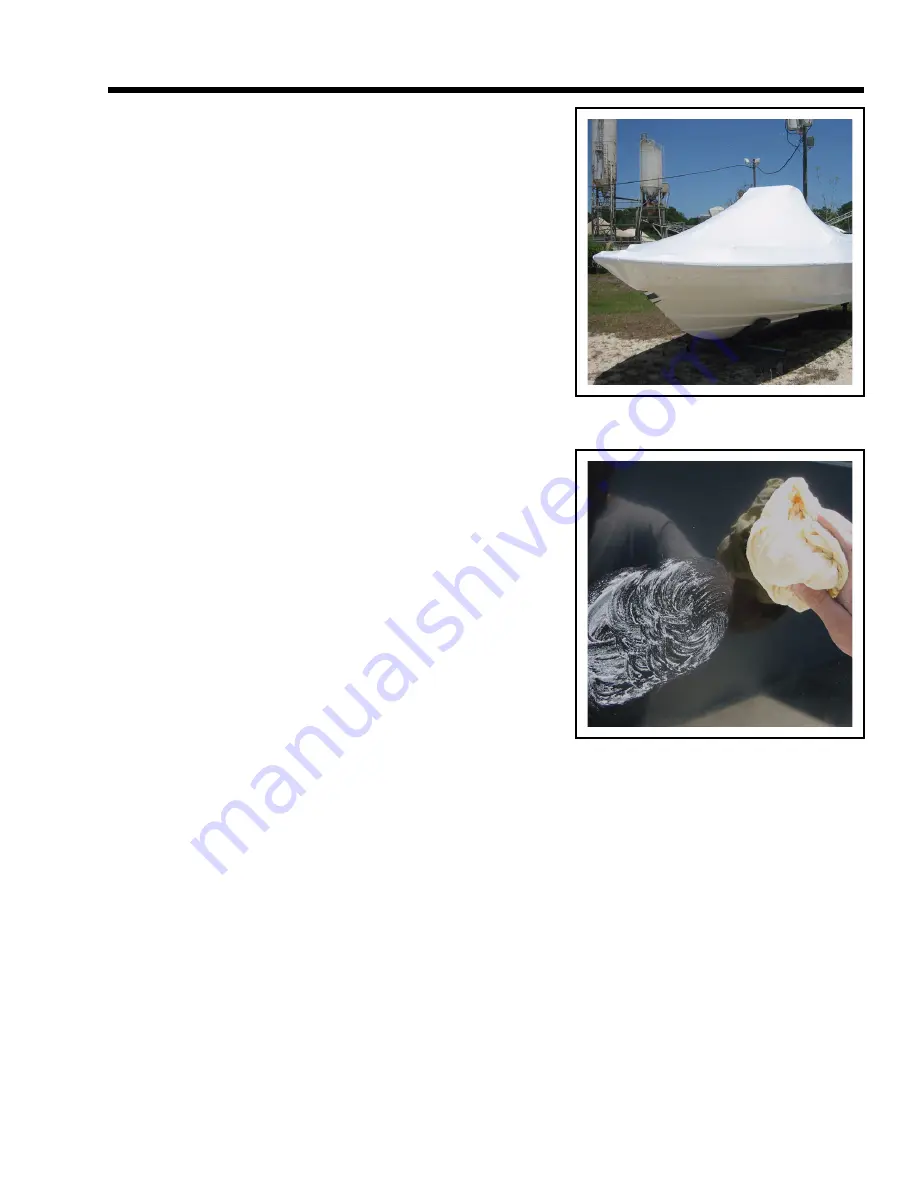

Waxing

Applying a high-quality wax formulated for marine use

can slow the hydrolysis process. Be sure the boat bot-

tom is clean and follow all of the wax manufacturer’s

recommendations.

Bottom Painting

Painting the bottom of your boat slows the formation of

blisters and controls marine growth. Bottom coatings

fall into two general categories, barrier coating and

conventional bottom painting.

Summary of Contents for Boston Whaler 26 Justice Series

Page 14: ...1 10 Operator Notes...

Page 76: ...4 18 Operator Notes...

Page 94: ...5 18 Operator Notes...

Page 111: ......